Thin films often fail on repeatability, not temperature

For photovoltaics and optoelectronics, performance is tied to interfaces, defects, and composition. That makes repeatable thermal history a core requirement. In many labs, variability comes from cool-down behavior, atmosphere differences, and user timing rather than from maximum temperature capability.

Why RTCVD architecture fits these workflows

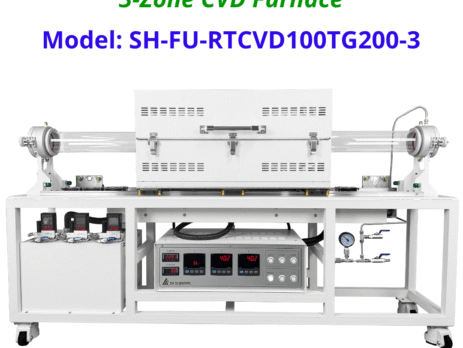

RTCVD is positioned as designed for high-purity thin film deposition using rapid heating technology in controlled atmospheres, and short thermal cycles are described as helpful for minimizing diffusion and defects. The furnace-movement design supports rapid thermal transitions without relying on a lamp-based RTP system.

Core configuration details

RTCVD100TG200-3 supports a 1200 C maximum temperature, a 100 mm tube configuration, and three independent 200 mm zones for a 600 mm heated length. This combination supports R&D workflows where larger fixtures or multiple samples benefit from a longer controlled region.

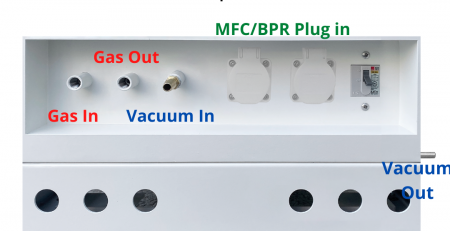

Atmosphere and gas control options to highlight

Photovoltaics and optoelectronics recipes often benefit from stable, documented gas conditions. Vacuum and inert atmosphere operation are highlighted, and MFC and BPR are listed as optional capabilities. If multiple teams will share the furnace, consider options that make recipe conditions repeatable across users.

Operational note: ramp guidance

For heater durability, the operation guidance recommends avoiding sharp, rapid increases in temperature and suggests about 15 C per minute as an ideal ramp-up rate.