Tube Furnace for Battery Research

By our industry’s standards, SH Scientific is a small team that delivers big things.

Oftentimes, that includes highly customized equipment that suits ultra-specialized processes, sustains extreme conditions, or provides extraordinary capacity.

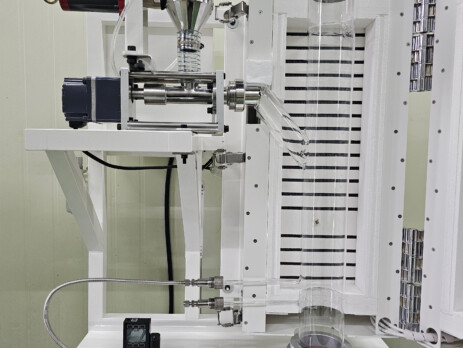

One recent example was a vertical electric tube furnace delivered to Korea Maritime and Ocean University (KMOU). The team knew and trusted the SH name, but required a vertical model to conduct very specific research on rechargeable batteries for marine use.

That was outside our standard line of horizontal models, but well within our customization capabilities.

Now, following successful production and real-world use, we’re excited to offer this vertical tube furnace to other teams conducting similar work on battery technology.

Below, we’ll cover some of the unique purposes that vertical tube furnaces serve, then walk through the design choices that make this model worth offering.

Background: Tube Furnaces in Battery Research

These days, Li–ion batteries power everything from earbuds to grid storage facilities. As surging demand stretches lithium supplies and poses environmental concerns, there’s a profound urgency for more efficient battery design.

Even the smallest improvements reflect extensive and painstaking laboratory work under carefully controlled conditions. To achieve such conditions, researchers often choose tube furnaces for more precise thermal and atmospheric control.

Just within the realm of battery research, some of their key applications are:

Material Synthesis

Most rechargeable batteries utilize materials with complex crystal structures. To synthesize these materials, precursor chemicals are often heated in controlled environments (e.g., a tube furnace) to form compounds with the desired microstructure and behavior for use in an electrode.

Thermal Treatment

Electrode materials often undergo thermal treatments to enhance their electrochemical properties. A tube furnace can be used to anneal these materials under specific atmospheres, which can enhance the material’s conductivity, stability, and overall performance.

Lifecycle Testing

Batteries are prone to “thermal runaway,” wherein overheating leads to still higher temperatures and, eventually, catastrophic failure. Tube furnaces give researchers a safe environment in which to simulate and study these conditions, ultimately leading to safer battery technologies.

Solid Electrolyte Research

Solid-state batteries promise higher energy densities and enhanced safety compared to liquid electrolytes. Solid electrolytes require exceptionally precise thermal management, for which tube furnaces are indispensable.

Diffusion Studies

Battery performance largely reflects the manner in which lithium or other ions diffuse. High-temperature diffusion studies in tube furnaces help researchers understand this phenomenon under both everyday and more extreme conditions.

The Unique Role of Vertical Tube Furnaces for Battery Research

This opens up possibilities for enhanced or entirely different thermal processes, some of which were employed by the team at Korea Maritime and Ocean University.

Liquid Catalyst Spraying

Liquid catalysts may coat substrates more evenly, especially when working with precursors for chemical vapor deposition. By spraying downward in a vertical chamber, gravity can help maximize the uniformity of its coverage, leading to more consistent reactions across the entire material.

High Temperatures

Tube furnaces in general excel at temperature gradient control. Vertical tube furnaces enhance it further by taking advantage of convection currents, which tend to transport heat vertically.

Horizontal and vertical chambers can both distribute heat evenly (when designed well and configured properly) but it’s often easier in the latter.

Gas Substitution

It can be difficult to achieve full, controlled, and replicable gas substitution at atmospheric pressure. Vertical tube furnaces allow introduction of gases from the top, from which they flow downward for more consistent and thorough interaction with the material.

Oxygen-Free Atmosphere

Along those lines, a vertical orientation provides a reliably oxygen-free atmosphere when equipped with a gas mass flow controller and back pressure regulator. (Note that these upgrades are available for all SH Scientific tube furnaces, including our standard horizontal models.)

Powder Accumulation

Powders such as cathode/anode materials have a tendency to settle unevenly and potentially clog portions of horizontal chambers.

In vertical chambers, gravity helps to collect powders in an unobstructive lower pocket. This reduces the risk of clogging or contamination, which in turn helps keep the material pure and consistent.

Adjustable Height

On a more pragmatic note, our vertical tube furnace is easily positioned for the user’s ergonomics and comfort. The full range of height adjustment is usable, with no effect on performance.

Choosing a Vertical Tube Furnace

The right furnace configuration can unlock novel techniques and groundbreaking results.

Developed in conjunction with the team at KMOU, our vertical tube furnace provides world-class performance and support.

It also highlights the degree of customization that we regularly deliver to customers—often at a surprisingly accessible price.

To inquire about our vertical tube furnace, or to discuss further customizations for your own lab, please contact our US sales team.