Real-World Performance: SH Scientific’s Large-Capacity High-Vacuum Muffle Furnace

At SH Scientific, we recognize that for materials science researchers, process control and repeatability are paramount. To provide the scientific community with reliable, real-world benchmarks, this report presents internal test data on the performance of our SH-HV40T turbo-molecular pump system. This data is intended to help researchers select equipment that ensures process integrity and consistent results, especially when working with large-volume vacuum furnaces.

This report details the validated performance of our SH-HV40T turbo-molecular pump system when paired with our 31-liter SH-FU-31MGV vacuum muffle furnace (315 x 315 x 315 mm chamber), highlighting its capabilities for advanced research applications.

The Challenge: Achieving a Stable High Vacuum in Large Chambers

A stable, high vacuum environment is crucial for developing advanced materials, as it prevents unwanted reactions with atmospheric gases. While small quartz tube furnaces work well for reaching a deep vacuum quickly, their size limits sample throughput and geometry. Large chamber muffle furnaces are necessary for processing bulky components or larger batches, but their significant internal surface area, particularly porous ceramic insulation, presents a major outgassing challenge, making it difficult to achieve and maintain a stable high vacuum.

Our Protocol for Validated Data

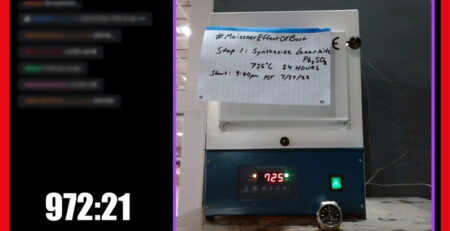

To generate data that researchers can rely on, we followed a thorough, step-by-step protocol.

- System Configuration: The test utilized an SH-FU-31MGV furnace with an upgraded ISO 100 vacuum port to ensure maximum pumping efficiency. The primary system was the SH-HV40T, a 6-inch turbo-molecular pump paired with a 312 L/min oil rotary vane pump, valued for its clean and rapid high-vacuum performance. For comparison, an SH-HV100, an 8-inch diffusion pump with a 960 L/min oil rotary vane pump, was also tested.

- Furnace Bakeout: To minimize outgassing, the furnace underwent a critical 48-hour bakeout at 600°C under continuous vacuum. This process is vital for removing adsorbed moisture and other volatile contaminants from the porous ceramic, enabling the system to reach a deeper and more stable ultimate vacuum.

- Test Conditions: After the bakeout, the chamber was purged with dry nitrogen. The pump-down test was then conducted at room temperature with no load or heating to isolate and measure the performance of the vacuum system itself. Pump warm-up times were excluded from the measurements.

Validated Performance Results

Our tests produced clear, quantitative data on the system’s real-world capabilities. The data below summarizes the key performance milestones for both the turbo-molecular and diffusion pump systems.

SH-HV40T (6” Turbo-Molecular Pump + 312 L/min Rotary Pump)

- Atmospheric Pressure to 2.0×10−4 Torr: 90 minutes

- 2.0×10−4 Torr to 7.5×10−5 Torr: 90 minutes

- Total Time to Ultimate Pressure: 3 hours

- Note: The system was unable to reach the 10−6 Torr range.

SH-HV100 (8” Diffusion Pump + 960 L/min Rotary Pump)

- Atmospheric Pressure to 5.0×10−4 Torr: 100 minutes

- Note: The system was unable to reach the 10−5 Torr range.

The results confirm the SH-HV40T turbo-molecular pump achieves a significantly deeper vacuum, a critical factor for providing the stable environment required for sensitive research applications.

Applications for the Modern Research Laboratory

A furnace system that can reliably achieve a validated vacuum in the mid-10−5 Torr range is an essential tool for innovation. This level of performance enables stable and repeatable processing for:

- Novel Alloy and Metallurgy Research: In processes like sintering, annealing, and brazing of reactive metals (e.g., titanium), a stable high-vacuum environment is non-negotiable. It prevents oxidation and nitridation, ensuring the final material achieves its desired mechanical properties and microstructure without contamination.

- Advanced Battery Development: The development of next-generation battery technologies requires strictly controlled processing environments. This furnace system provides the stable, inert atmosphere needed for drying electrode plates, sintering high-nickel cathode materials without oxidation, and preparing solid-state electrolytes in a moisture-free vacuum.

- Ceramics and Composite Synthesis: When synthesizing high-performance technical ceramics, a controlled atmosphere is essential for preventing defects like porosity, which compromise material strength. The clean, stable vacuum of this system minimizes reactions with residual gases, ensuring uniform densification and predictable material properties.

- Professional Recommendations for Researchers

This data confirms that the SH-HV40T turbo-molecular pump system can reliably produce a stable high-vacuum environment in the mid-10−5 Torr range, even in a large, outgassing-limited furnace.

- For Processes Requiring a Stable High Vacuum: For applications where preventing oxidation and ensuring process repeatability are critical, the SH-HV40T is the superior choice. Its clean, hydrocarbon-free operation and ability to achieve a deeper ultimate vacuum deliver the stable environment necessary for advanced materials research.

- For Other Vacuum Muffle Furnace Models (1500°C 18.7MHV, 1800°C MSV series): For larger furnaces, we recommend the SH-HV40T for processes requiring the 10−5 Torr range. Expect pump-down times to be approximately 30 to 50 minutes longer than those recorded here.

We understand that researchers often face unique challenges. Based on our extensive internal data, the engineering team at SH Scientific can provide expert recommendations to ensure you select the optimal system configuration for your specific experimental needs.