Cooling is part of the recipe in 2D materials

For graphene and many TMDC workflows, cool-down is not just waiting time. It can influence phase behavior, defect evolution, and surface reactions with residual gases. When different users cool differently, results drift and optimization slows.

Why furnace movement helps in real labs

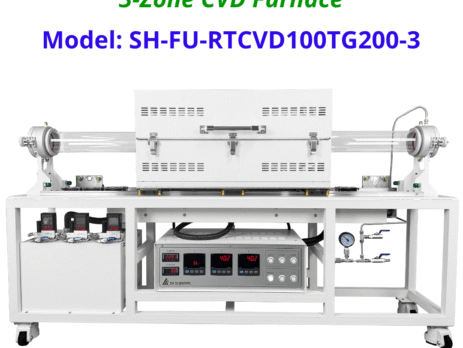

The RTCVD architecture uses a movable furnace body so hot-zone exposure can be programmed and repeated. In automatic mode, the furnace ramps and stabilizes, moves into position to begin rapid heating of the material, then moves away to begin rapid cooling at the end of the hold. This makes recipe timing more consistent and reduces uncontrolled tail reactions during slow cool-down.

Configuration details that matter for 2D workflows

This model supports a 100 mm tube configuration with a 600 mm total heated length (200 mm x 3 zones) and a 1200 C maximum temperature. That combination is useful when you run multiple samples, use larger fixtures, or need a longer controlled region.

Atmosphere conditioning and optional gas control

A programmable preheating stage is intended to establish the desired atmosphere before rapid heating begins. For 2D materials, controlling trace oxygen and moisture can matter.

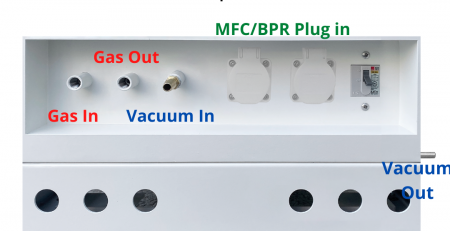

Options such as MFC and BPR can help standardize gas delivery and pressure behavior from run to run. Quartz fixtures such as a diffuser and wafer carrier can also improve consistency.

Operational note: ramp guidance

The operation guidance recommends avoiding sharp, rapid increases in temperature and suggests about 15 C per minute as an ideal ramp-up rate for durability. Use movement-based exposure for rapid thermal effect while keeping heater ramp behavior conservative and repeatable.