Why 3-zone control matters for CVT and crystal growth

Many crystal growth and transport experiments depend on a defined axial profile. Multi-zone control provides flexibility to shape temperature along the tube and to keep a profile stable during long holds.

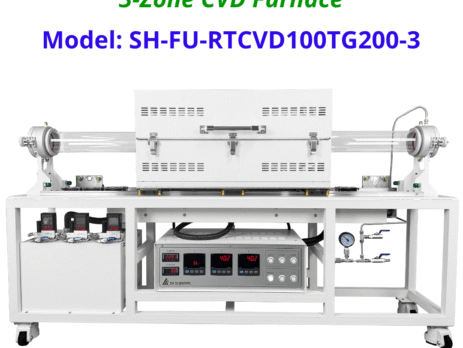

What the RTCVD100TG200-3 provides for gradient-driven workflows

RTCVD100TG200-3 provides three independent 200 mm zones for a 600 mm heated region, with programmable control. This geometry can be used to define a source region, gradient region, and growth region along the tube axis.

What RTCVD adds beyond multi-zone heating

In static setups, the end of an experiment often involves turning power off and waiting while reactions continue under changing conditions. RTCVD adds movement-based transitions so sample exposure can be changed as part of the recipe.

In automatic mode, the system ramps and stabilizes, moves into position for rapid heating, and moves away to begin rapid cooling at the end of the hold. For many labs, that makes termination behavior more consistent than a long passive cool-down.

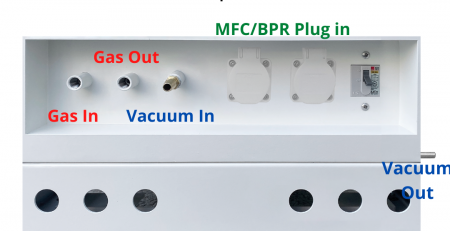

Atmosphere and pressure options that match transport workflows

Vacuum and inert atmosphere operation are supported, and MFC and BPR are listed as optional components. For gradient-based experiments, stable gas delivery and controlled pressure can be as important as temperature setpoints.

Operational note: ramp guidance

For heater durability, the operation guidance recommends avoiding sharp, rapid increases in temperature and suggests about 15 C per minute as an ideal ramp-up rate.