What lab managers need that papers do not mention

In shared labs, the cost is not only purchase price. It includes training, repeatability across users, downtime, and avoidable damage from inconsistent operation.

A good platform makes it easier to standardize recipes and reduces user-dependent variability.

Automation and recipe discipline

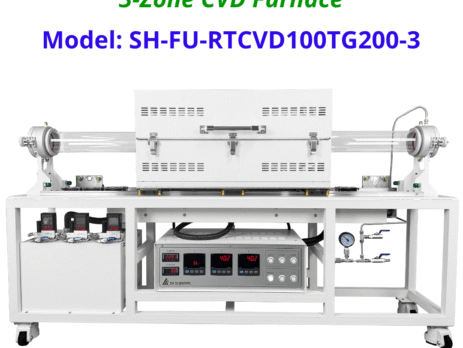

The platform supports dual modes: automatic mode for rapid thermal RTCVD cycles and manual mode for conventional CVD operation. This is useful when a facility supports both rapid recipes and longer steady holds.

A programmable preheating stage is intended to establish the desired atmosphere before rapid heating begins. This helps facilities standardize purge and atmosphere conditioning steps.

Safety devices and facility planning basics

- Safety devices listed include: electric leakage circuit breaker and over temperature controller

- Electrical requirements (100TG200-3): 220V, 50/60Hz, 1 phase, 26A

- Heater capacity: 2.0 kW x 3 zones (6.0 kW total)

Option planning: decide early

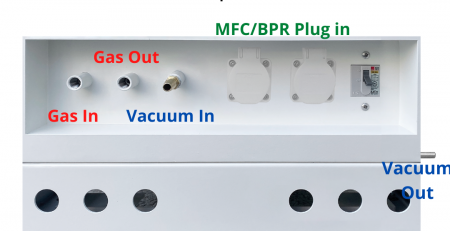

MFC, BPR, quartz gas diffuser, and quartz wafer carrier are listed as options. When deciding on a configuration, align options to user needs:

If multiple groups will share gas recipes, MFC helps. If experiments require controlled backpressure or overpressure, BPR helps. If users run wafers or fixtures, a wafer carrier improves consistent placement. If gas distribution is a known variable, a quartz diffuser can help.

Ramp guidance to include in training

The operation guidance recommends avoiding sharp, rapid increases in temperature and suggests about 15 C per minute as an ideal ramp-up rate. Including this as a rule in SOPs helps protect heating elements and reduces unplanned downtime.