Why gas control options matter

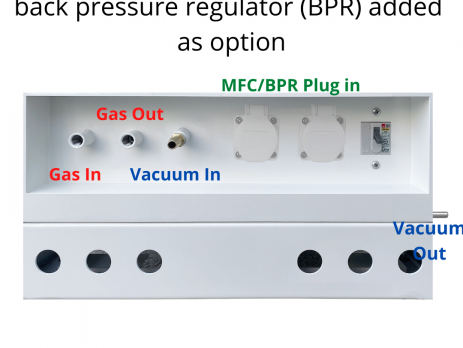

If your experiment relies on a controlled atmosphere, gas control often determines repeatability. Two options commonly requested on advanced tube furnaces are MFC and BPR. Both are listed as available options for this series.

What an MFC helps you do

A mass flow controller helps you set and reproduce gas flow rates programmatically. This is useful when gas ratios matter, when you want recipe automation, and when multiple users need to reproduce the same gas conditions.

What a BPR helps you do

A back pressure regulator helps you maintain a controlled pressure condition. This is useful when you need stable backpressure during gas flow or when you operate under controlled overpressure conditions.

Quick selection checklist

- Choose MFC if you need reproducible flow setpoints, gas ratios, and automated recipes

- Choose BPR if pressure stability matters or if you need controlled backpressure or overpressure

- Choose both if you need both reproducible flows and stable pressure

- Confirm all gas and vacuum requirements with your lab safety and facilities team

Related quartz hardware options

Quartz gas diffuser and quartz wafer carrier are also listed as options. A diffuser can support more uniform distribution, and a wafer carrier improves repeatable placement for wafer or fixture-based work.