Batch Type Rotary Tube Furnace: Easy and Reliable Handling of Fine Powders and Nanotube Materials

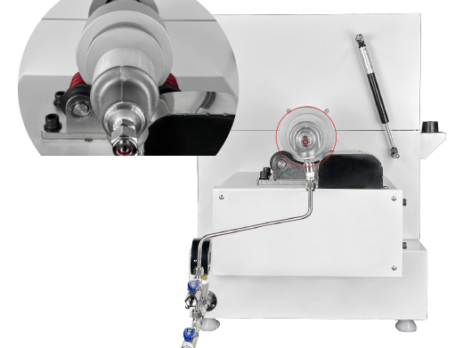

For researchers handling highly dispersible powders, delicate nanotube materials, or other challenging samples, conventional rotary tube furnaces relying on steep tilt angles simply aren’t effective. When working with nanotube materials in particular, removing the samples after each run often becomes extremely difficult—even fully inverting the tube at 90 degrees frequently fails. Many of our clients expressed frustration with this persistent issue, prompting SH Scientific to engineer a more practical, optimized solution. Our batch-type rotary tube furnace eliminates the hassle of steep angles entirely, allowing slow, controlled rotation at 2 rpm to maintain consistent contact between samples and the heated environment. By focusing on exactly what researchers need and discarding outdated design elements, we provide higher quality equipment at a significantly better value.

Removable Stainless Steel Tube for Quick Sample Clearance

A key innovation is our robust stainless steel tube, designed to slide out easily at the end of each run. Researchers can quickly and effortlessly remove samples by simply tapping or firmly banging the tube on the ground over a container, clearing residual powders or granules in seconds—no tedious disassembly or complicated inversion required. Additionally, the stainless steel construction ensures durability and easy cleaning between processes. To further enhance lab productivity, many clients order multiple tubes upfront; while one tube is being cleaned, another can be immediately inserted, ensuring uninterrupted workflow and maximum efficiency. For applications genuinely requiring adjustable tube angles, our dedicated Rotary Kiln line still offers precise angle control, ensuring labs receive exactly the functionality their research demands.

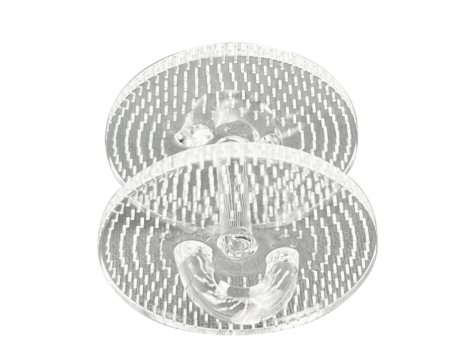

Barrier Options for High-Dispersibility Materials

To address sensitive or drifting materials, the furnace offers several barrier configurations. A stainless steel tube can include a fixed, welded barrier on one end to keep samples contained during rotation. For ultra-fine or nanotube materials, a quartz tube with a built-in barrier on one side and a removable barrier on the other provides extra protection against premature dispersal into the catcher. This arrangement prevents powders from spreading uncontrollably inside the tube while still allowing convenient loading and unloading.

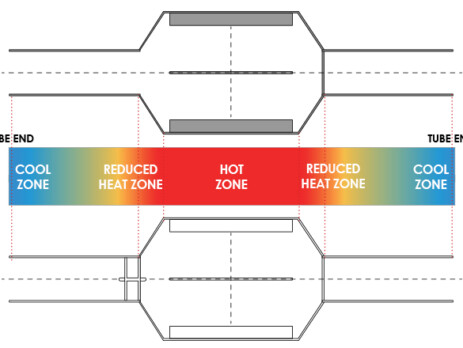

Ultra-Pure Water and Steamer Integration

Many labs performing delicate research rely on ultra-pure water to generate steam and maintain a contaminant-free environment. However, beyond purity control, introducing steam at high temperatures can help facilitate partial thermolysis of H₂O into O₂ and H₂ within the furnace chamber. This controlled release of reactive oxygen and hydrogen species can significantly enhance certain chemical reactions by accelerating oxidation or reduction steps. By carefully managing the steam flow, researchers can optimize the partial pressures of O₂ and H₂, promoting faster and more precise chemical transformations. This furnace is fully tested to maximize performance when connected to a compatible water filtration system and steamer, ensuring that the chamber can be purged or filled with steam as needed. This integration supports specialized applications in material science, semiconductor processes, and any research requiring either high-purity conditions or reactive steam-based environments for O₂/H₂ separation and improved reaction kinetics.

Simplicity That Addresses Real Research Needs

By eliminating unnecessary mechanical complexity and focusing solely on features that genuinely benefit laboratory work, SH Scientific delivers a rotary tube furnace that is both practical and reliable. Every detail, from the slow rotation speed to the removable stainless steel tube and optional barriers, stems from direct feedback gathered from modern labs. The result is a well-rounded solution that meets the demands of researchers handling sensitive, high-dispersibility materials—providing stable heating and straightforward operation without the complications of traditional tilt designs.