Why semiconductor teams care about short thermal cycles

In semiconductor process development, thermal budget drives outcomes. Extra time at elevated temperature can increase dopant diffusion, broaden interfaces, and raise defect risk. That is why teams look for rapid thermal workflows that deliver the needed chemistry while limiting time at temperature.

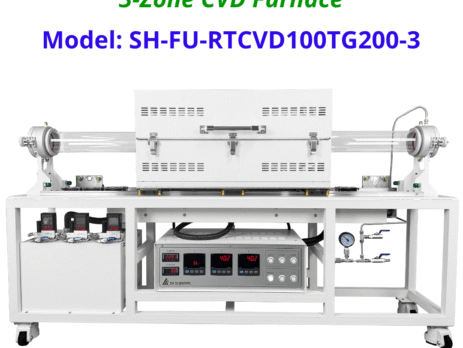

What the RTCVD100TG200-3 provides

RTCVD100TG200-3 combines a 1200 C capability with three independent heating zones (200 mm each, 600 mm total heated length) and a 100 mm tube configuration. This supports repeatable thermal processing for R&D scale devices and test structures.

Rapid thermal behavior by furnace movement

The differentiator is the furnace-movement design used to control when the sample is inside or outside the hot zone as part of the recipe. In automatic mode, the furnace ramps and stabilizes, moves into position for rapid heating, and then moves away to begin rapid cooling at the end of the hold time. This helps reduce variability caused by manual timing and inconsistent handling.

Where 3-zone control helps

Three independent zones can support longer samples and fixtures, and can also be used to shape axial profiles when a process benefits from a structured temperature layout. If your team is moving from a short hot zone to a longer one, the 600 mm heated length is an important practical difference.

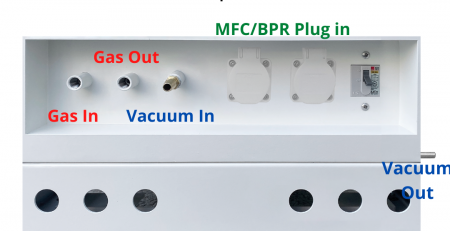

Atmosphere and gas control options to consider

- MFC (optional): improve repeatability of gas recipes and enable programmable flow setpoints

- BPR (optional): help maintain controlled backpressure or overpressure conditions

- Quartz diffuser and wafer carrier (optional): improve gas distribution and sample placement consistency

Operational note: ramp guidance

The operation guidance recommends avoiding sharp, rapid increases in temperature and suggests about 15 C per minute as an ideal ramp-up rate for durability. When planning recipes, use movement-based exposure for rapid thermal effect and keep heater ramp behavior within manufacturer guidance.