Healthcare & Medical Applications of Tube Furnaces

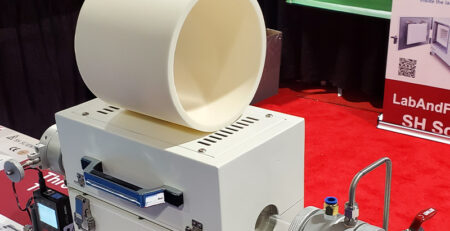

SH Scientific tube furnaces equip healthcare labs for state-of-the-art implants and analyses.

Our design ensures minimal temperature differences from the center to the ends of each heating chamber. This is possible thanks to state-of-the-art ceramic insulation, Kanthal (1200°C), SiC (1500°C) and MoSi2 (1800°C) heating elements.

In addition, programmable digital controllers enables you to perform multiple steps of firing and sintering per your experimental scenario by setting ramp up & holding time.

What’s a Tube Furnace?

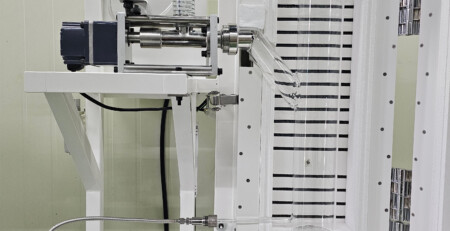

A tube furnace contains a central cylinder (the “tube”) surrounded by electrical heating elements connected to a controller. The tube and heating elements are all made of temperature-specific materials that provide the right balance of cost and longevity for the intended operating conditions.

The horizontal, tubular chamber allows for exceptionally even heat distribution, rapid temperature adjustment, and complete atmospheric control. This is an ideal environment for small samples subject to high yet precise heating, even through multiple stages of treatment.

Healthcare & Medical Applications of Tube Furnaces

3D printing is an emerging and potentially revolutionary technique for some types of implants. It allows for rapid prototyping, exceptional predictability, and minimal adjustment during surgery.

But printed materials—often ceramic or metal powders—may remain brittle and porous unless sintered or annealed. Other materials need to be softened with heat treatment so that a surgeon can gently and safely adjust them during the implant procedure.

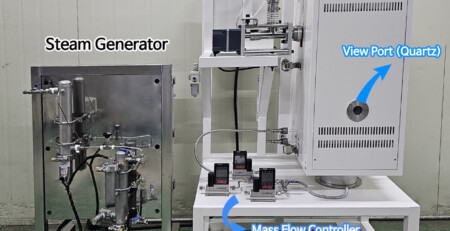

All these cases require precise temperatures, of course, and often inert gases to prevent undesired reactions like oxidation. Tube furnaces are purpose-built to fulfill exactly these needs. They ensure even temperatures, total gas flow control, and programmability for safe, trustworthy thermal treatment.

Tube Furnaces for 3D-Printed Healthcare Products

Today, 3D printing is most widely used for implants or replacements of hard tissues, but its frontiers are continually expanding. Some of the most common uses include:

- Dental restorations and oral/maxillofacial implants

- Spinal implants

- Orthopaedic implants, including complex joints

- Surgical equipment and devices

- Models for training, research, and surgical planning

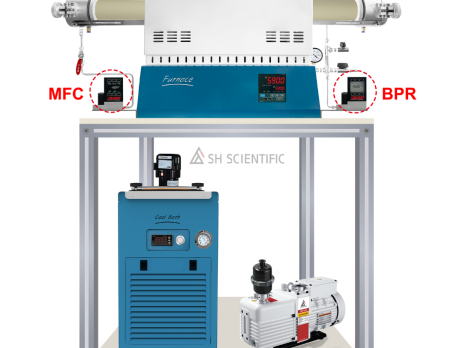

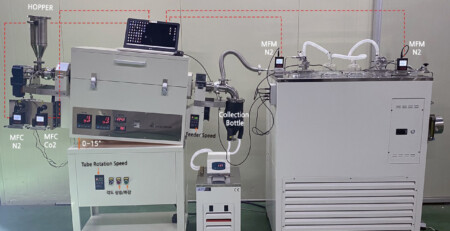

These cases are well suited to tube furnaces, which offer extremely high operating temperatures (up to 1800°C) with uniformity of ±1°C. Our turn-key solutions also include gas flow controls, a vacuum pump, and chiller for consistent treatment at scale.

In case of spinal implants made of titanium alloy powder, annealing is a mandatory step to refine and smooth the rough surface of the medical implants since they are initially produced by powder and it is performed around 800°C or so. During annealing, there is a high possibility that you suffer with oxidation which makes the surface of implants turn blackish unless the heat treatment process is perfectly done under non-oxidizing environment with inert gases filled and positively maintained inside tube.

It is your task to find your own surface treatment protocol with trials and errors whether you like it or not. And our vacuum tube furnace turn-key system will mitigate your burden and greatly help you to find a perfect protocol without failure resulted from furnace’s poor configuration.

Additional Tube Furnace Applications

Some facilities use tube furnaces for entirely different purposes: not to create medical materials, but to break them down.

For example, ashes and waste gases can reveal critical biological and material information. However, these tests are only useful insofar as they follow exacting time and temperature standards.

To that end, a tube furnace is a popular and versatile choice for smaller samples. It offers precise control over multiple phases of heating, cooling, and atmospheric changes. All the above are programmable to ensure consistent, reproducible results.

Why Use an SH Tube Furnace?

We understand that your work affects human lives, regulatory standing, as well as the bottom line. There’s simply no room for ambiguous temperature or atmospheric control.

Every SH tube furnace provides fully programmable temperature management, with rapid heating/cooling and high uniformity you can trust.

We equip medical implant, 3DP, and analysis labs with:

- Programmable digital controller for one-, two-, or three-zone use (up to 1800°C ± 1°C)

- Up to four ball type gas flow meters, upgradeable to a digital mass flow controller and back pressure regulator

- Low-noise vacuum pump for peaceful, focused working conditions

- Optional recirculating chiller

- Several tube and hot-zone sizes to suit your facility

We’re proud to offer Korea-built, USA-supported tube furnaces to today’s healthcare innovators.

Please contact us today for detailed specifications or to request a custom quote.