Innovative Turn-Key Tube Furnace Systems for Doping, Annealing, Oxidation, and CVD in Semiconductor Research

Established in 1982, SH Scientific, a leading manufacturer of laboratory equipment, has recently introduced advanced tube furnace turn-key systems that seamlessly integrate various semiconductor manufacturing processes, including doping, oxidation, annealing, and chemical vapor deposition.

Simplifying Semiconductor Research

Typically, conducting experiments for semiconductor research and development requires four separate tube furnaces, each dedicated to a specific wafer processing step: doping, oxidation, annealing, and chemical vapor deposition. Each of these furnaces needs its own set of sealing masks, tubes, and a gas flow system. Our Gas Flow Package model, such as SH-FU-100STG-WG, meets these requirements.

However, many laboratories struggle with space constraints, making the installation of four Gas Flow Packages challenging.

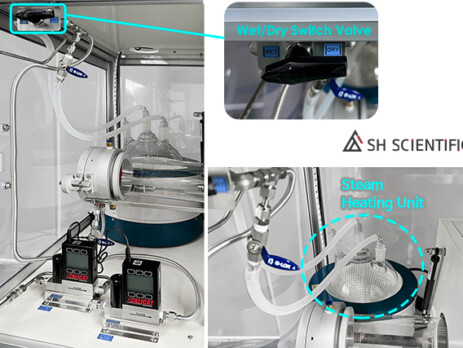

Our innovative turn-key system addresses this issue by incorporating two Gas Flow Packages into a single safety frame (cabinet). This design prevents tube damage and external contamination during experiments while conserving valuable laboratory space.

User-Friendly Design

The cabinet is designed with doors that fully open on the front, left, and right sides, providing researchers with excellent accessibility and ease of use. Additionally, a 200mm exhaust port is installed on the top of the cabinet to effectively reduce heat buildup and prevent contamination from fumes. This exhaust port can be easily connected to the laboratory’s existing exhaust system, ensuring a safe and controlled environment during high-temperature experiments.

Custom-Made for Your Needs

Our tube furnace turn-key systems are custom-made to meet the specific requirements and conditions of each laboratory. The system includes four Gas Flow Packages: one for n-type doping, one for p-type doping, one for oxidation, and one for annealing and chemical vapor deposition.

Detailed Process Descriptions

Doping

Doping involves adding impurities to the silicon crystal in the wafer, conducted in an inert gas environment (mainly nitrogen or argon) using the diffusion method. Depending on the type of impurity, doping is classified into n-type (phosphorus, arsenic) and p-type (boron, aluminum).

Oxidation

The oxidation process can be performed using two methods:

- Wet Oxidation: This method is fast but produces a thicker oxide layer.

- Dry Oxidation: This method is slower but results in a more precise oxide layer.

Our oxidation tube furnace is designed to handle both methods. In the Wet Oxidation process, a steam generation unit is installed within the oxidation furnace, allowing carrier gas to transport generated steam into the reaction tube. In the Dry Oxidation process, oxygen gas flows directly into the reaction tube without passing through the steam-generating unit. Both methods can be selected and operated through simple valve manipulation.

Annealing and Chemical Vapor Deposition (CVD)

The annealing and CVD processes share a single gas flow package, streamlining operations and optimizing space.

Advanced Control and Customization

Our turn-key system features precise gas flow control, including inert gases (nitrogen, argon) and oxygen used in the oxidation process, through a Mass Flow Controller (MFC). A Back Pressure Regulator (BPR) ensures positive gas pressure within the reaction tube, maintaining an oxygen-free environment and enabling accurate oxide layer formation.

For example, if a researcher inputs +40mmHg into the BPR, it maintains the tube pressure precisely at 40mmHg above the laboratory atmospheric pressure. Assuming the atmospheric pressure is 760mmHg, the tube pressure would be set to 800mmHg. The system allows pressure units to be set to 20 different options, enabling researchers to use their preferred units.

Additional Features

In addition to wet and dry oxidation, the oxidation process can also be performed in a vacuum environment without injecting oxygen gas. For high vacuum requirements (below 0.0005 Torr), additional vacuum pumps, either oil rotary or oil-less types such as dry scroll or dry screw, can be purchased.

Positive Reception and Global Supply

Our turn-key system for semiconductor process experiments has received positive feedback from research laboratories and is currently being supplied to many universities worldwide. SH Scientific remains committed to providing innovative solutions that enhance the efficiency and accuracy of semiconductor research and development.