Tube Furnaces for Laboratories

SH Scientific’s laboratory tube furnaces are the choice of research, engineering, medical, and specialty manufacturing facilities.

We’re proud to offer exceptionally uniform hot-zone temperature distribution, inside one of the most compact sliding tube designs on the market.

What Is a Tube Furnace?

A tube furnace applies extremely high heat to a small, cylindrical chamber. It’s a mainstay of labs that perform thermal testing, treatment, and processing.

The basic design dates back more than a century, but today’s models make extensive use of proprietary ceramics and alloys, digital controllers, and precise instrumentation.

Why Use a Tube Furnace?

Tube furnaces are used to treat small samples at ultra-high temperatures. They’re common for complex but low-volume processes in both industrial and academic settings.

Tube Furnace vs. Muffle Furnace

Both are capable of similar temperatures, and can be equipped with vacuums and inert gas management systems. They’re equally suited to delicate applications, like graphene production by CVD.

The key difference is muffle furnaces heat a relatively large chamber—ideal for samples that don’t readily fit in a tube furnace.

However, the cylindrical nature of a tube allows more precise and immediate control of temperature and gas flow. Its exposed ends are also conducive to managing temperature gradients, especially with the help of multiple controllers.

Common Uses

In both commercial and research facilities, tube furnaces often facilitate or produce:

- Semiconductors and batteries

- Thermocouples & mineral-insulated cables

- Vacuum brazing and heat treatment

- Vacuum curing and sintering

- Water, waste, and soil testing

- Aerospace ceramic and metals testing

- Oil and gas analysis

- Solid oxide fuel cells

- Polymer composites and graphene

Types of Tubes

Our furnaces are available with one of three temperature-specific tube materials.

Quartz tubes are suitable up to 1200°C. They’re the most cost-effective option, and their transparency is helpful for some applications. However, quartz generally can’t withstand as many heat-cool cycles as other materials.

Alumina tubes can handle temperatures up to 1800°C. They’re much longer-lived and more durable than quartz, but are not transparent.

Finally, superalloy tubes like Inconel are available as a custom option. These are recommended for even more extreme temperatures, e.g., in the range of jet and rocket engines.

SH Scientific Tube Furnace Features

As an all-in-one system, your SH furnace ensures simple purchasing and administration, efficient service, and highly competitive pricing.

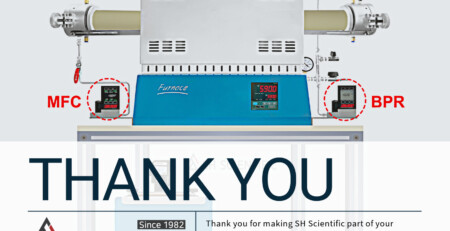

Unlike most other tube furnaces, ours include more than just a furnace body. We can supply a professionally pre-assembled gas management system including:

- The furnace itself

- Ball type gas flow meter or digital mass flow controller

- Back pressure regulator

- Gas flow line with valves

- Aluminum sealing mask

- Quartz or alumina tube

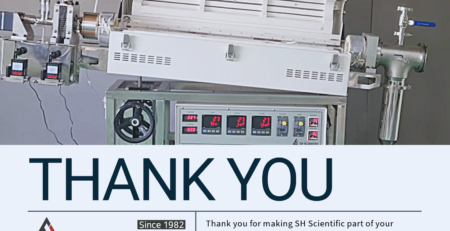

Unique among furnace suppliers, we can also configure a turn-key vacuum tube furnace package, including:

- Recirculating chiller to protect silicone seals from hardening (and eventually leaking gas) due to high temperatures

- Low-noise vacuum pump for quiet, focused working conditions

This distinctive and creative system enables scientists and researchers to experiment in a zero-oxidation atmosphere and under a changing atmosphere as needed (e.g., air → vacuum purging → gas filling).

Furthermore, all SH tube furnaces emphasize safety and usability.

Our uniquely compact sliding tube design facilitates rapid cooling and convenient loading/unloading, while saving space in tight quarters. Double housing ensures a low surface temperature of about 29-30°C while operating at 800°C.

All configurations offer some of the most uniform temperature distribution currently possible. Standard options include a tube size (i.e., diameter) of 50, 80, 100, or 120mm with a hot zone of 300 or 600mm. (Hot zones up to 900mm are available as a custom option.)

Our furnaces can use up to three programmable, digital controllers for exceptional uniformity and/or more precise gradients. This is particularly helpful for larger hot zones of 600mm and up.

Maximum temperatures are either 1200, 1500, or 1800°C—all produced by long-lasting heating elements made of Kanthal, SiC, or MoSi2.

Pricing & Customization

Our standard tube furnace configurations suit most facilities without modification. However, several customizations are possible for dimensions, materials, power, and controls.

We encourage you to explore the line, or to contact us directly for technical inquiries or customization requests.