The Geometry of Quenching: Why SH Scientific RTCVD Unlocks “Real” Rapid Thermal Processing

In the fabrication of silicon microelectronics and MEMS devices, thermal management is not merely about reaching a temperature; it is about strictly controlling the time at temperature. This concept, known as the “thermal budget,” dictates the performance of every transistor and contact. Whether activating dopants or sintering metal contacts, the goal is often the same: get heat into the wafer to trigger a specific reaction, and then remove it instantly to stop unwanted diffusion.

For decades, researchers have faced a hardware gap. Standard diffusion furnaces provide uniformity but are too slow, leading to “smeared” dopant profiles. Industrial lamp-based Rapid Thermal Processing (RTP) tools offer speed but are notoriously expensive and difficult to calibrate for different wafer emissivities.

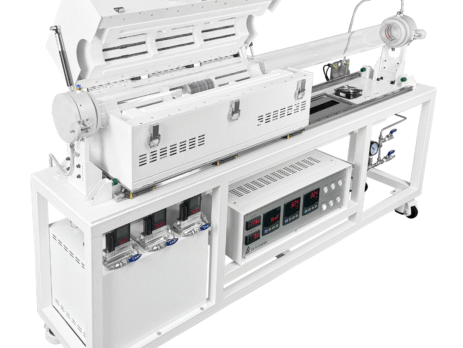

The SH Scientific Sliding Tube Furnace bridges this gap. It delivers the kinetic control required for semiconductor R&D not through complex lamp arrays, but through “Reasonable Design”: a calculated combination of a sliding furnace architecture and an extended tube geometry that enables “Real” Rapid Thermal Processing.

The Engineering of “Real” Rapid Cooling

To understand why this system succeeds where standard furnaces fail, one must look at the physical footprint. In many lab furnaces, “rapid cooling” is a marketing term that simply means turning off the power and opening a vent. This is insufficient for semiconductor work because the sample remains trapped inside a hot ceramic chamber that acts as a thermal battery, radiating heat for hours.

The Geometric Necessity of Space This system is designed around a fundamental physical truth: to stop a thermal reaction instantly, you must physically separate the sample from the heat source.

This requires space. The system features an extended rail mechanism and a quartz tube significantly longer than the heating element itself.

- The Heated Zone: The furnace body typically contains three independent heating zones.

- The Cooling Zone (Parking Area): The rail system allows the furnace to travel a distance greater than its own length.

This Reasonable Design ensures that when the furnace slides away, it completely clears the sample position. The wafer is not left in the “shadow” of the hot zone. Instead, it is left suspended in the center of the quartz tube, surrounded only by ambient air. This physical decoupling allows for cooling rates that effectively “freeze” the state of the silicon device, preserving the atomic structure engineered at peak temperature. This is the core mechanism that makes Rapid Thermal Processing possible in a tube furnace format.

Flash Annealing for Dopant Activation

This geometric advantage allows for precise control over dopant activation. After ion implantation, atoms like Boron or Phosphorus sit in interstitial sites where they are electrically inactive. To activate them, the lattice must be healed at high temperatures, typically between 900 and 1100 degrees Celsius. However, if the heating ramp is slow, the dopants will diffuse vertically and laterally before the lattice heals, destroying the shallow junctions required for high-speed devices.

The extended rail design allows the Parking Area to serve as a “Pre-Heat Staging Zone.” The furnace heats to the target temperature while parked away from the sample, leaving the wafer safely in the cold zone. Once stable, the automation slides the pre-heated furnace over the wafer, creating a near-instantaneous step-function in temperature. The lattice heals and dopants activate within seconds before the furnace slides away immediately. This “Step-and-Slide” capability mimics the performance of industrial Rapid Thermal Processing tools, creating sharp, highly activated junctions without the complexity of flash lamps.

Silicide Contact Formation

The same kinetic control applies to the formation of low-resistance contacts. Reacting metals like Titanium or Nickel with silicon to form silicides is highly phase-sensitive. For example, forming the low-resistance C54 phase of Titanium Disilicide requires a precise thermal soak followed by a rapid exit to prevent agglomeration.

The system’s 3-zone control ensures that the temperature is perfectly flat across the entire wafer surface, ensuring phase transformation happens uniformly from the center to the edge. Simultaneously, the sliding mechanism allows for the “Instant Termination” of the sintering process. By sliding the furnace to the Parking Area, the reaction stops dead, preventing the over-growth of the silicide or the formation of unwanted high-resistance islands.

Oxide Interface Control

The value of this kinetic control extends to dielectric growth as well. Growing ultra-thin thermal oxides or annealing Atomic Layer Deposition (ALD) dielectrics requires strict control over interface quality. In a static furnace, the cooling phase acts as an uncontrolled growth period, adding unpredictable thickness to the oxide layer. By utilizing the “Real” rapid cooling provided by the decoupled design, researchers can achieve digital control over oxide thickness. The reaction ends exactly when the dwell time expires, ensuring that the final film thickness matches the calculated target.

Geometry is Performance

This level of digital control over thin films highlights a broader truth about equipment design in this sector: geometry is performance. The SH Scientific Sliding Tube Furnace demonstrates that meeting the strict thermal budgets of modern silicon devices does not always require the complexity and maintenance costs of lamp-based systems.

By implementing a “Reasonable Design”, specifically, an extended tube and rail system that provides the necessary space for total thermal decoupling, the system transforms the humble tube furnace into a precision kinetic instrument. For the semiconductor researcher, this geometric advantage is what finally bridges the gap between basic laboratory equipment and industrial precision, unlocking the benefits of Rapid Thermal Processing for the R&D environment.