SH Scientific Pilot Scale Rotary Kiln

Bridging R&D and Commercial Production

Pilot plant rotary kilns have become a favored choice for laboratories moving beyond lab-scale testing but not yet ready for full commercial-scale equipment. By enabling critical scale-up validation, SH Scientific’s pilot plant scale rotary kiln provides a vital link between research and industrial production.

This kiln delivers industrial-grade precision, reliable performance, and scalable controls designed specifically for transitioning laboratory results to full-scale production.

Key Specifications

- Tube Options:

- Stainless Steel 310S: Maximum heated length of 5200 mm, supporting up to 16 heating zones. Available diameter options include Ø165 mm, Ø267 mm, and Ø318 mm.

- Operating Temperature:

- Continuous operation up to 1000°C

- Thermal Conditioning:

- Dedicated pre-heating & post-heating zones

- Atmosphere Control:

- Gas inlet/outlet ports for inert/reactive gases (N₂, CO₂, steam), dedicated exhaust port

- Pressure Range:

- Exceptional custom sealing allows operation from vacuum to positive pressure.

- Tube Rotation:

- Adjustable RPM, bidirectional rotation capability

- Voltage Options:

- 220V / 380V / 480V (3-phase power compatibility)

- Material Handling:

- Standard single-vessel design (feeding & receiving)

- Optional special double-vessel airlock design with automatic pneumatic butterfly valves (feeding & receiving)

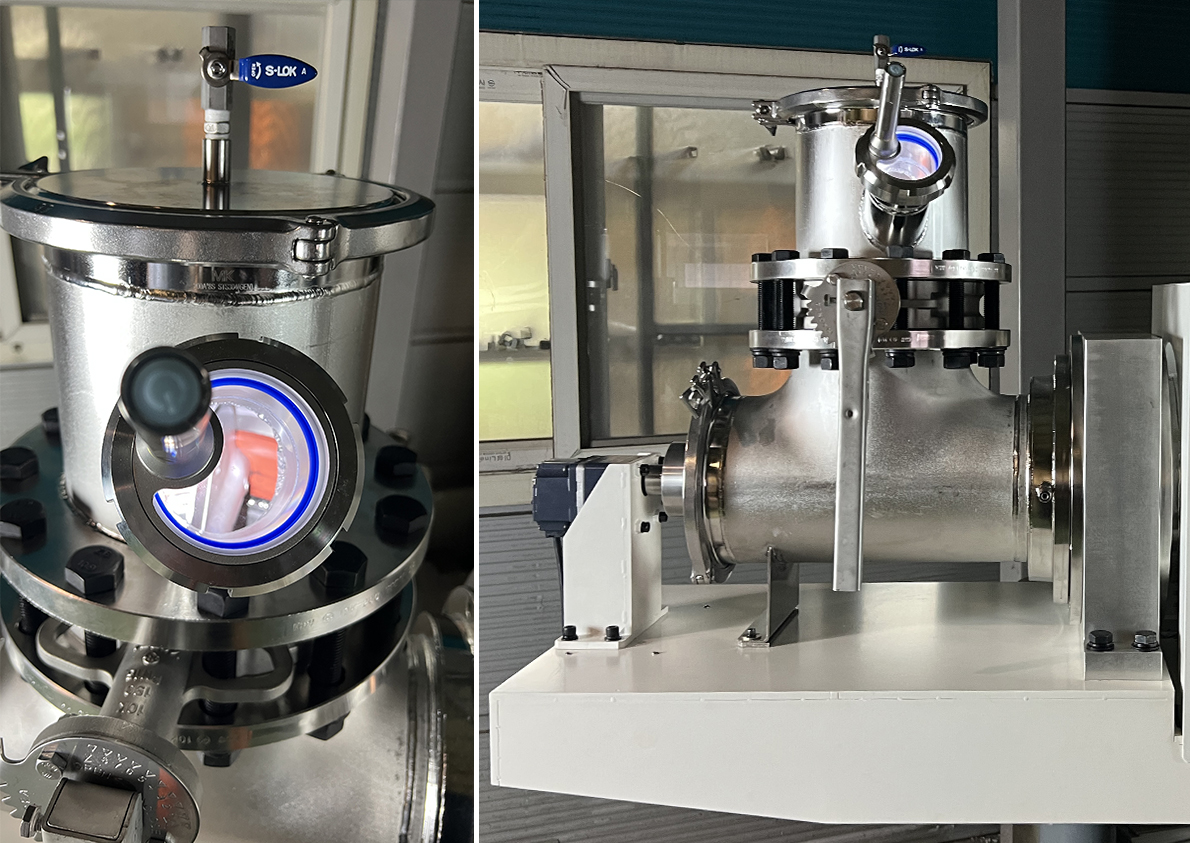

- Observation Windows:

- Quartz sightglass with integrated LED illumination for clear monitoring of samples during operation

- Additional Heating:

- Heating jackets on vessels to prevent condensation and enhance temperature uniformity

(All dimensions and performance values are nominal; custom configurations available upon request.)

Convenience Features:

- Inspection Window at Feeding Port: A robust, heat-shielded viewing port enables operators to monitor material entry without interrupting kiln operation.

- Sightglass for Real-Time Monitoring: Located at the discharge end, the quartz sightglass with internal LED lighting allows operators to directly observe sample processing, enhancing quality assurance and process validation.

Common Industry Applications

- Bioenergy: Biomass torrefaction, pyrolysis, and biochar production

- Advanced Materials: Calcination and precursor phase transformations

- Catalyst Development: Catalyst aging and steam reforming studies

- Circular Economy: CO₂ mineralization and waste valorization

- Specialty Ceramics: Controlled binder burnout and sintering processes

Reasons Pilot Plant Rotary Kilns are Favored in Process Engineering

- True Scale-up Continuity: The kiln employs identical control logic, sensors, and operating principles as SH Scientific’s full-scale equipment, simplifying industrial scale-up.

- Versatile Atmosphere Handling: Integrated gas ports for inert/reactive gases (N₂, CO₂, steam) enable accurate replication of production conditions.

- Precision Thermal Control: Multiple independently controlled heating zones deliver ±1°C uniformity, eliminating thermal gradients.

- Safe & Clean Operation: 310S stainless steel or quartz tubes resist corrosion; double-vessel airlocks and heating jackets ensure safe, contamination-free processing.

- Global Voltage Compatibility: Operable with standard electrical systems (220V, 380V, 480V) for ease of installation in laboratories worldwide.

Comprehensive Support from Lab to Commercial Scale

SH Scientific provides complete assistance from initial validation through full-scale production, including:

- Custom Engineering: Tailored materials, tube dimensions, and heating zone configurations to fit your specific needs.

- Process Optimization: Expert consultation on thermal profiling, PID control optimization, and scale-up methodology.

- Regulatory Documentation: Support with detailed documentation packages for CE, UL, SEMI S-class, and global safety compliance.

- Global After-Sales Support: Worldwide field service, spare parts availability, and remote diagnostic services.

Contact us today for detailed product information, technical consultation, or visit our dedicated product page for technical drawings and data sheets.

Your path from laboratory discovery to commercial reality deserves equipment engineered specifically for growth.