Why cooling matters as much as heating

In advanced materials synthesis and thin film processing, most labs focus on the heat-up and dwell steps. But the cooling step often becomes the uncontrolled part of the experiment.

That matters because outcomes can be set during cool-down, including phase stability, dopant distribution, defect evolution, and interfacial reactions. If cool-down varies with load size, tube condition, ambient airflow, and operator behavior, reproducibility suffers.

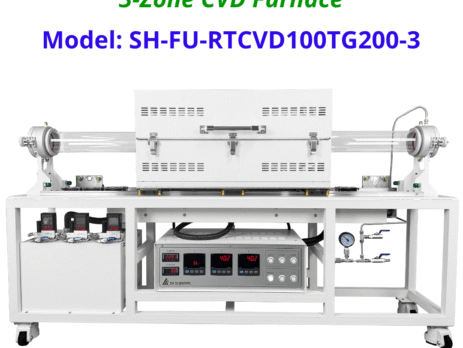

What the RTCVD100TG200-3 is

RTCVD100TG200-3 is a rapid thermal CVD tube furnace platform built around a movable furnace body. The key idea is simple: change sample exposure to the hot zone as part of a programmed recipe, instead of relying only on passive cooling after power-off.

How the furnace moves to control heating and cooling

Traditional tube furnaces have a fixed hot zone. Even after heater power is reduced, the sample still sees a large thermal mass and radiative heat.

In the RTCVD approach, the furnace body moves relative to the process tube. The automatic mode sequence is designed so the furnace ramps and stabilizes, moves into position to begin rapid heating of the material, then moves away to begin rapid cooling at the end of the hold time. This motion is part of the thermal history and can be automated as a repeatable recipe step.

Operating modes: automatic vs manual

- Automatic mode: optimized for rapid thermal RTCVD cycles

- Manual mode: optimized for conventional CVD operation

- Both modes use programmable control so labs can standardize recipes across users.

Verified specification snapshot (manufacturer listing)

- Max temperature: 1200 C

- Tube diameter configuration: 100 mm

- Heating zones: 200 mm x 3 zones (600 mm heated length)

- Controller: programmable controller (SP 570)

- Sensor: K type

- Heater capacity: 2.0 kW x 3 zones (6.0 kW total)

- Heater element: Kanthal A-1

- Insulation: ceramic board and wool

- Electrical requirements: 220V, 50/60Hz, 1 phase, 26A

- Safety devices: electric leakage circuit breaker, over temperature controller

- Options listed: MFC, BPR, quartz gas diffuser, quartz wafer carrier

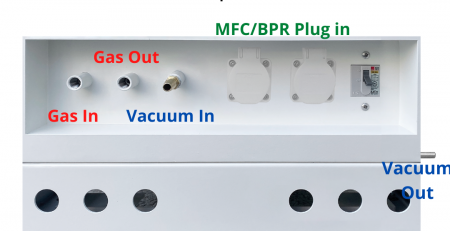

Atmosphere control and option planning

Many experiments require more than temperature. They require repeatable gas delivery and a controlled atmosphere.

Optional components such as MFC (for precise gas flow control) and BPR (for controlled backpressure or overpressure), as well as quartz hardware such as a gas diffuser and wafer carrier, can support more repeatable results. Options vary by configuration, so confirm what is included and what is optional for your quote.

Ramp strategy and heater durability

Rapid thermal behavior does not mean forcing heating elements to ramp aggressively. The operation guidance recommends avoiding sharp, rapid increases in temperature and suggests about 15 C per minute as an ideal ramp-up rate for durability.

Many labs use the movement-based exposure of the sample to achieve rapid thermal processing effects while keeping the furnace ramp profile conservative and repeatable.

Typical application areas

Common application fields include semiconductor thin films, doping processes, oxide and nitride films, advanced materials such as graphene and nanostructures, photovoltaics, display and optoelectronics, and aerospace and energy device coatings.

When this model is a good fit

- You need rapid heating and rapid cooling behavior driven by furnace movement and programmable control

- You need 3-zone control across a 600 mm heated length

- You need a 100 mm tube configuration for larger sample fixtures or multiple samples

- You want a single platform that can support both rapid thermal RTCVD cycles and conventional CVD operation