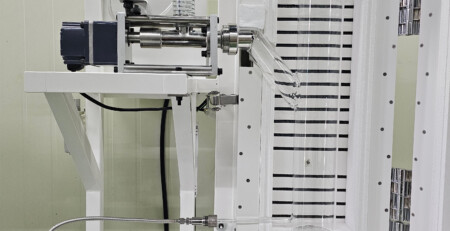

Advanced Tube Furnace Door

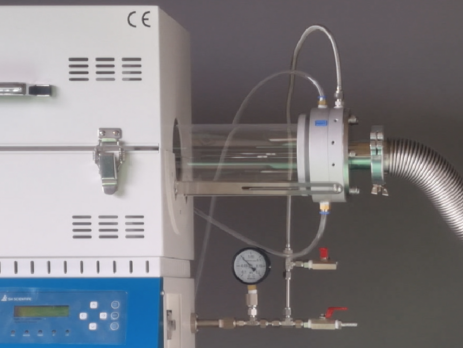

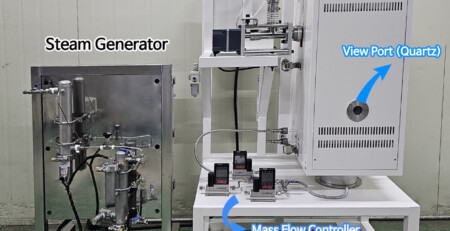

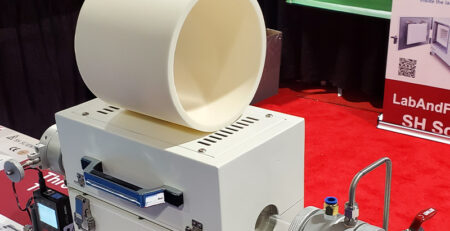

Our water cooling system keeps sealing gaskets supple for trustworthy vacuum performance and inert-gas management.

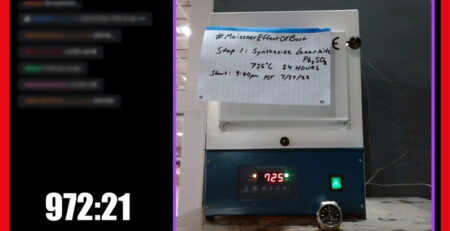

Tube furnaces use silicone gaskets to seal off each end of the tube from its door assembly. Unfortunately, silicone hardens after frequent and prolonged heat exposure.

As the gaskets become less pliable, their sealing ability deteriorates. Little by little, they cease to maintain a vacuum and to control inert gas saturation.

The bad news is that such gradual performance loss can be hard to detect.

The good news is that simple, active cooling technology can largely prevent it.

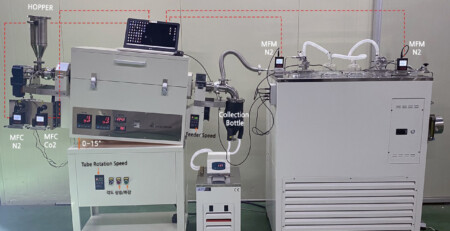

Our water-cooled sealing assembly is the first of its kind, with a recirculating chiller that reduces the gaskets’ heat exposure through continuous cooling. Why water, and not a specialized coolant?

- Coolants are typically viscous, resulting in a low flow rate. Water lends itself to a higher flow rate, resulting in less demand on the recirculating chiller.

- The elevated flow rate allows for a cost- and energy-efficient temperature of just 20° C, compared to the usual -10° to -20° C.

Efficient cooling plus our signature easy-access hinged door add up to the most convenient, dependable tube furnaces on the market.