Vacuum Muffle Furnace for Biomass Decomposition

Our vacuum muffle furnace gives biomass decomposition researchers a more space-efficient alternative to tube furnaces.

Tube chambers excel at inert gas management, making them a standard choice for pyrolysis work.

But they have one significant drawback: extremely limited chamber size. Cylindrical chambers are challenging with large or bulky samples.

That means more cycles, more energy use, and more opportunities for error.

Our customers simply needed more capacity for biomass pyrolysis, but without the staggering cost or energy consumption of the largest tube furnaces.

Based on feedback from real-world labs, including USDA facilities, we developed one of the only vacuum muffle furnaces on the market.

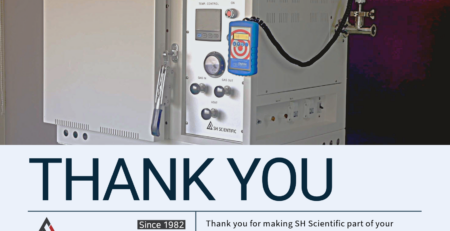

The SH Scientific Vacuum Muffle Furnace

Standard muffle furnaces aren’t suitable when oxidation is a concern.

They make great use of space, but struggle with inert gas saturation. Since streamlines don’t cross, there’s no way to fully saturate near corners at atmospheric pressure.

Our vacuum muffle furnace overcomes this limitation thanks to a vacuum pump, mass flow controller, and back pressure regulator. The result is full saturation, with all the capacity and flexibility of a muffle chamber.

This enables:

- Essentially oxygen-free environments for biomass pyrolysis

- Precise temperature control for optimal yield (e.g., of bio-oils)

- Fewer cycles compared to standard tube furnaces

- Multiple environments or stages of gas saturation

- All the programmability and precision of our trusted, standard muffle furnaces

Our line includes maximum temperatures of 1200° C or 1500° C and volumes from 1.5 L to 31 L.

These are appropriate for most of our customers’ sites and use cases, but we can modify virtually any specification to meet unique needs.

Vacuum Muffle Furnace Customization

As a manufacturer, we have the engineers and equipment to customize your vacuum muffle furnace.

We’re also small enough to do this at a more compelling price—even for a single unit—than huge, multinational firms can offer.

For instance, the USDA contacted us in need of a voluminous 137 L furnace. (For comparison, our largest stock furnace measures 31 L.) The team also required an integrated cold trap bath to protect the vacuum pump and to keep any oil vapors out of the chamber.

Our team designed and delivered this highly customized furnace which now enables cutting-edge research on biomass yields and byproducts.

The Role of Furnaces in Pyrolysis

Controlled pyrolysis is a standard means of decomposing waste and residual biomass into energy sources.

This process, by definition, requires an environment devoid of oxygen. It also requires precise and consistent temperature control, since heating parameters determine the actual yields of oil, char, and gases.

Our vacuum muffle furnaces deliver this through three technologies:

- A digital mass flow controller is the most precise, responsive, and stable way to control the flow of inert gases.

- A back pressure regulator maintains positive pressure inside the chamber to prevent oxygen ingress.

- Optionally (but highly recommended), a condenser/cold trap bath operates at ~40° C to capture moisture and solvents that may otherwise contaminate the vacuum pump.

Building the Future of Bioenergy

We’re honored to supply bioenergy innovators with a range of Korea-made, USA-supported furnaces.

Customers trust our intuitive and reliable equipment for repeatable results, a straightforward user experience, and unmatched value.

If you’re looking to equip or upgrade your facility, then please reach out to discuss your needs and learn more about our purchase and customization processes.