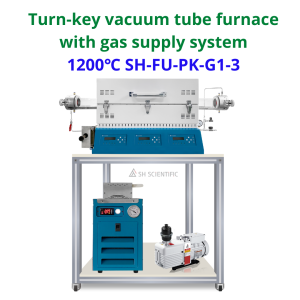

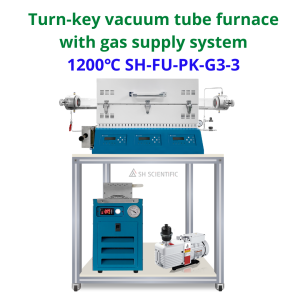

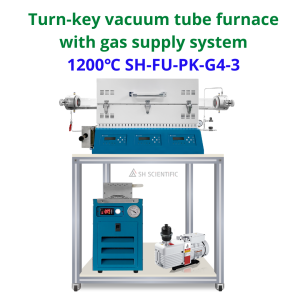

G2-3-S – 1200°C – SH Vacuum Tube Furnace Turnkey System

$15,321

- Harmful gas & fume removal protects laboratory air quality

- Three-stage filtration system. Pre-filter, HEPA filter and VOC filter

- Adjustable airflow. 10 levels of air intake and exhaust volume adjustment

- Ductless operation

- (Optional) Testo 300 Combustion Gas Analyzer for Monitoring Oxygen-free atmosphere inside the chamber or tube and measure combustion gas and synthetic gas components – Contact us for available options

- (Optional) Laboratory Gas-Drying Unit by Drierite™ with Connector

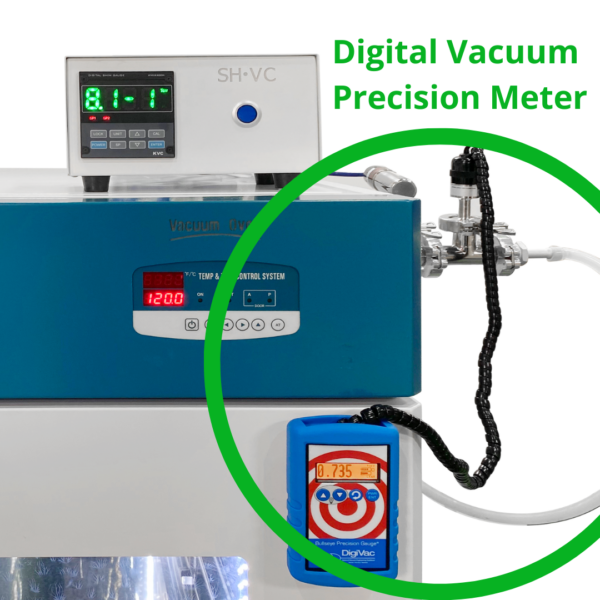

- (Optional) Digital Vacuum Precision Meter by DigiVac

Also available in 80mm tube size, 100mm tube size and 120mm tube size.

- Vacuum tube furnace with recirculating chiller and vacuum pump *Moving cart is just for an image and not included

- 80mm (3″) diameter

- 3 independent hot zones with 3 controllers. 3 x 200mm (8″) hot zones. Total 600mm (24″) hot zone

- Max temp 1200°C and recommended ideal running temp below 1000°C

- Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

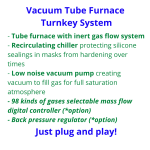

- Inert gas flow management system including ball type gas flow meter, aluminum sealing masks and stainless steel 316 valves and pipes. Quartz tube included

- Perfect turnkey system for non-oxidation atmosphere experiment and treatment after pulling vacuum

- Fast cool down with inert gas flow

- Nearly assembled for your plug and play

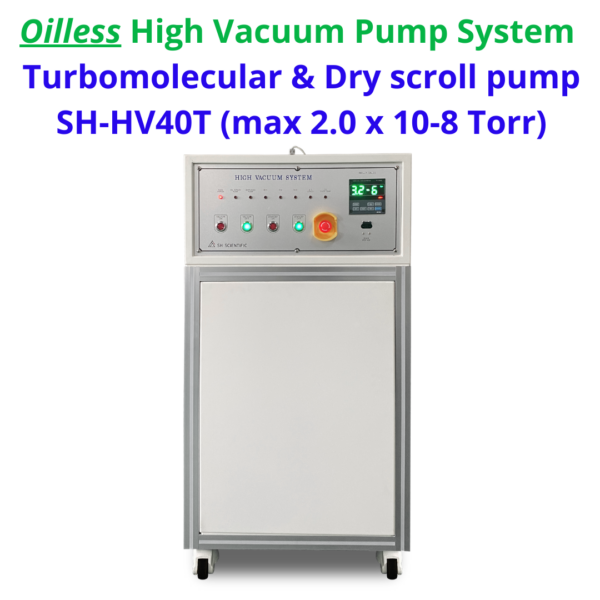

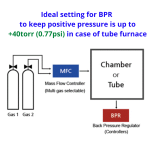

- Optional 98 multi gases selectable mass flow controller and back pressure regulator

- 50/80/100/120mm tube available.

- Great durability thanks to Kanthal heating element

- Light weight and prompt heat up thanks to ceramic insulation

- Convenient design for sample loading

- Built in over temp protector

- SSR operation and built in programmable controller provides low noise operation and precise temp control (+/-1°C)

- Description

- Specification

- Customer Photos

- Documents

- FAQ

Description

Description

Built in South Korea, our tube furnaces offer unparalleled efficiency and versatility. Every model delivers industry-standard performance and endless customization, all at surprisingly accessible prices.

- Standalone tube furnace (STG/LTG series): Ideal for basic applications requiring precise heating.

- Tube furnace with gas flow management (WG series): Enhances control over atmospheric conditions, perfect for sensitive experiments.

- Turn-key vacuum tube furnace system (PK-G series): A comprehensive solution including a gas flow management system, vacuum pump, and chiller for advanced research needs.

Technical Excellence

SH Scientific’s tube furnaces are increasingly used in cutting-edge fields, including secondary and graphene battery research, polymer composites, and 3D printing material treatment.

Whatever configuration you choose, you and your team can expect:

- Wide temperature range: PK-G series operates at up to 1200° C with optimal performance at 1000° C.

- Programmable heating zones: Built-in 45-step controller for complex cyclic treatments, with heating zones of 1 x 300 mm (PK-G) or 1 x 600 mm (PK-G-L).

- Extensive tube size options: Standard diameters are 50mm(G1)/80mm(G2)/100mm(G3)/120mm(G4). Significantly larger diameters are available upon request.

- Rapid heating & cooling: Minimize wait times with efficient thermal management.

- Economical sample treatment: A cost-effective choice for processing small samples, especially with volatile materials or special atmospheric requirements.

- Advanced features: Digital programmable controllers, single or three hot zones, double-shell construction for stability, and customizable tube diameters.

Customization & Accessories

We specialize in gas flow management systems. Our turn-key vacuum tube furnace system (with recirculating chillers and low-noise vacuum pumps) is a popular upgrade for more seamless set-up and use.

This particular configuration features a seamless stainless steel 316 flow line; valve and connector; gas-tight sealing mask; and quartz, ceramic, or alumina tube.

Need something we haven’t listed here? Reach out to share your requirements and talk through more customized offerings.

Specification

|

Model |

SH-FU-80LTG-3-WG |

|

Max temperature |

1200℃ |

|

Continuous running temperature |

1000℃ |

|

Tube diameter |

80mm, 3″ |

|

Controller |

Programmable controller FC-1000 |

|

Sensor |

K type |

|

Heater |

1.8kW x 3 zones, total 5.4kW |

|

Hot zone |

200mm (8″) x 3 zones, total 600mm (24″) |

|

Heating element |

Kanthal A-1 with ceramic molding |

|

Insulation |

Ceramic |

|

External size |

850x400x570mm |

|

Weight |

56kg (furnace only) |

|

Power supply |

220V, 50/60Hz, 1p, 24A |

| Model | SH-WB-5CDR(-15) |

| Temp Range | -15°C to ambient |

| Temp Controller | Microprocessor membrane Digital PID Controller |

| Recirculating pump | Max flow 8L/min Max head 3.5meters Water proof IPX4 |

| Reservoir | 5 L |

| Dimension Internal | 200x200x130mm |

| Dimension External | 283x400x565mm |

| Net Weight | 26 Kg |

| Material Internal | Stainless Steel |

| Material External | Steel Plate with Powder Heating Coated |

| Electrical Requirements | 6.5 A

230v ,60Hz, 1Φ |

| Model No. | SH-VDC10 |

| Speed@60hz | 96L/min |

| 3.4 cfm | |

| Ultimate partial pressure gas ballast close |

|

| Ultimate total pressure gas ballast close |

5×10-2 Pa |

| Ultimate total pressure gas ballast open |

10 |

| Power supply | 110V~220V, 1phase |

| Power rating(kW) | 0.4 |

| Inlet/Exhaust flange | KF16/25 |

| Oil volume(L) | 0.6~1.0 |

| Noise level | <48 |

| Weight(kg) | 15 |

Customer Photos

Documents

Tube Furnace Features and Specification

Tube Furnace Turnkey System G Series Manual

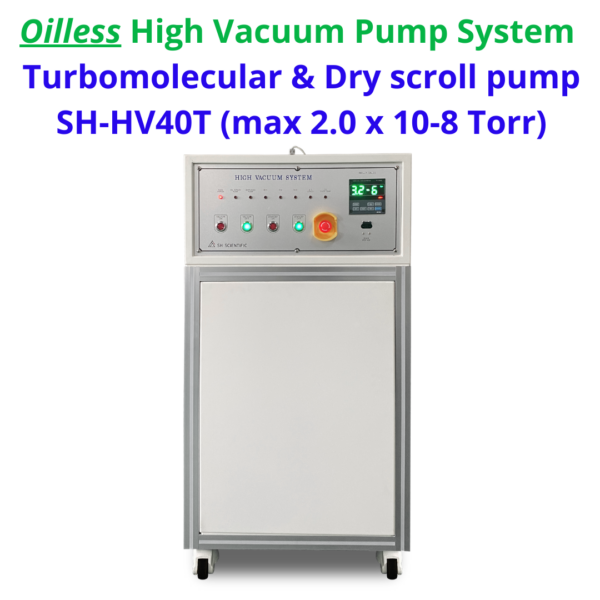

SH Scientific High-Vacuum System Manual

FAQ

Content missing