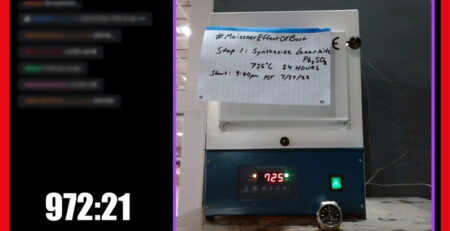

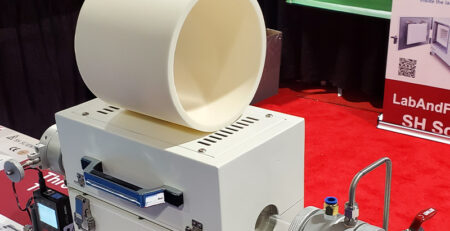

2023 Tube Furnace Performance Comparison

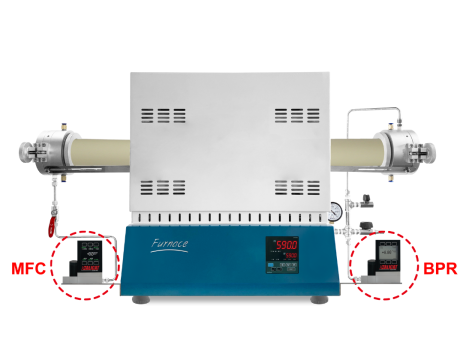

Stable and uniform temperature control is essential, but high-performance tube furnaces need to offer more.

A non-oxidizing atmosphere, vacuum retention, and maintenance of positive pressure are every bit as important.

SH Scientific furnaces excel in both respects—and at a compelling price, too.

What’s more, we’ve channeled years of customer feedback into unique features for safer and more convenient operation in busy labs.

Model comparison

We offer the only tube furnace line that matches the performance of well-known manufacturers and the price of distributor brands.

Let’s take a closer look at how SH furnaces compare to other offerings you may be familiar with.

| SH Scientific 1500° C series | Thermo Fisher Lindberg / Blue MSTF55 series | Across Int’lTF1400 | SH Scientific 1800° C | Carbolite Gero HTRH series | Thermo Fisher Lindberg / Blue MSTH54 series | |

| Max temp. | 1500° C | 1500° C | 1400° C | 1800° C | 1800° C | 1700° C |

| Recommended operating temp. | ≤ 1350° C | Unspecified | 1300° C | ≤ 1650° C | Unspecified | Unspecified |

| Tube diameter | 50 / 80 / 100 / 120 mm | 25 / 50 / 75 mm | 60 / 100 / 120 mm | 50 / 80 / 100 / 120 mm | Up to 100mm | 75 mm |

| Door type | Hinged | Solid | Solid | Solid | Solid | Solid |

| Hot Zone | 300 / 600 mm | 300 mm | 280 mm | 300 / 600 mm | Multiple | 300 mm |

| Casing for low surface temp | Double wall | Double wall | Single wall | Double wall | Double wall | Double wall |

| Heating element | SiC | SiC | SiC | MoSi2 | MoSi2 | MoSi2 |

| Vacuum available | Yes | Yes | Yes | Yes | Yes | Yes |

| Vacuum retention | 24 hours | Unknown | Unknown | 24 hours | Unknown | Unknown |

Specs and components are similar across the board, but SH furnaces deliver distinctive performance, customizability, and usability.

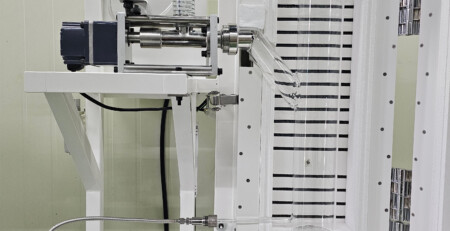

Active cooling for gasket longevity

We offer the first and only water cooling system to preserve gasket integrity.

Long-term heat exposure hardens silicone gaskets. As they lose their ability to seal, their vacuum retention also diminishes, potentially resulting in gas leaks or loss of positive pressure. This sort of performance loss is subtle, gradual, and often hard to detect early.

To maximize gasket longevity and performance, our tube furnaces are available with a chiller that continuously circulates 20° C water through a dedicated port in the door assembly.

This proprietary, water-based design is unique to SH Scientific.

User-friendly door design

Solid doors are common on higher-temperature tube furnaces. They’re certainly effective, but they require a degree of (dis)assembly to load and unload.

Hinged doors are more convenient, and simply a better experience for technicians. That’s why we’ve invested in a hinged design that’s safe and efficient for use on models up to 1500° C.

Even major manufacturers—like Nabertherm, Carbolite, and Thermo Fisher Scientific—still use solid doors on models that operate above 1300° C. To the best of our knowledge, only SH furnaces offer a convenient hinged door in this temperature range.

(As you may have noticed, we do use a solid door on our 1800° C model. So far, no alternative performs up to our standards at extreme temperatures.)

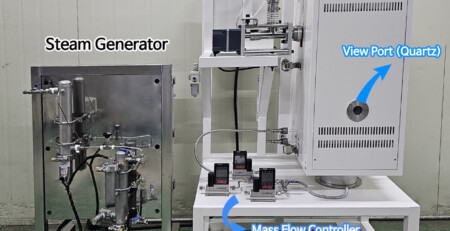

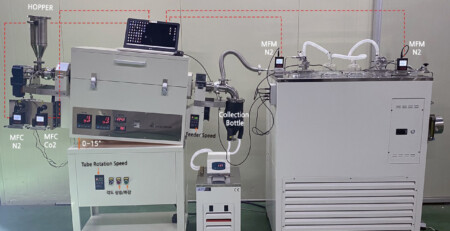

Greater choice in tube diameter & material

We offer a plethora of tube diameter and material combinations to suit your samples and workflows.

For instance, battery researchers often need a quartz tube to ensure cleanroom-like conditions (and more precise temperature control). Other facilities may need a furnace for extremely specific sample sizes in between the typical 50–60 and 120 mm options.

Between standard options and essentially unlimited customization, we can tailor a tube furnace to every aspect of your workflow.

Be wary of cheap alternatives

On marketplaces like AliExpress and Alibaba, you’ll notice some furnaces with striking similarities to ours. Those “bargains” are actually knock-offs of SH designs.

Even if we’re flattered by the imitations, they fall short in nearly every respect. Superficial similarities bely subpar performance, opaque safety and QA standards, and questionable (if any) support.

Vacuum performance

Our furnaces maintain a vacuum state for at least 24 hours without changes in atmospheric pressure. Internal testing found that certain knock-off models lost their vacuum and allowed oxygen into the chamber within about one hour.

Most simply couldn’t maintain positive pressure. Among the few that could, some proved susceptible to shocks, potentially leading to vacuum loss when loading/unloading the sample.

Door design

As mentioned earlier, we developed a hinged door for models rated up to 1500° C.

Imitators struggle to replicate it. For instance, one simply applied our solid 1800° door design to its 1400° model, creating a larger hassle than is really necessary for users.

Exterior temperature reduction

We use a double-wall design to minimize exterior temperature and reduce burn risk during operation. It’s a costly feature, but critical for safety, therefore standard on most name-brand furnaces.

Certain budget alternatives use only a single wall. The burn risk is exponentially higher, as is the burden of care and precautions for users.

End caps & cooling

Our proprietary end caps facilitate thermal management and loading/unloading. They do this equally well over the long term.

Imitations often rely on standalone O-rings. And they work…for a while. Unfortunately, they harden after repeated heat exposure and rapid heating/cooling cycles, resulting in a poor seal that undermines temperature control and jeopardizes atmospheric management.

Ordering an SH Scientific tube furnace

Every SH Scientific tube furnace is the product of extensive, real-world lab use. We’ve proudly equipped research universities, US government labs, and a vast range of private-sector R&D facilities.

Unlike distributor brands (and drop-shipped imitations), our line is built in Korea and supported by a US team during your business hours.

And unlike the largest manufacturers, our in-house engineers are available for highly custom, one-off orders.

To discuss technical specs, customization requests, or order details, please reach out today.