High Vacuum Pumps for the Future of Metals Manufacturing

SH Scientific’s high vacuum pump system helps 3DP and MIM manufacturers deliver superb finished products from oxidation-prone materials.

Rapid advancements in 3D printing (3DP) and metal injection molding (MIM) technology have turned the manufacturing world on its head.

Heat treatment addresses the structural shortcomings of 3DP titanium alloy parts, and removes the binders and release agents used in MIM.

However, these materials are especially sensitive to oxidation, so thermal treatment requires high-vacuum conditions.

Our high vacuum pumps are at the core of our world-class vacuum tube and muffle furnaces. They ensure reliable and uniquely cost-effective treatment of oxidation-prone materials.

Additive Manufacturing & Titanium Alloy 3DP

From outer space to inside our bodies, titanium alloys have become critical materials.

3D printing allows for endlessly complex geometries and custom designs, even at scale. That’s especially true of techniques like powder bed fusion (PBF) and selective laser melting (SLM).

But these advantages come with one enormous challenge: reduced fatigue strength.

According to internal tests at one medical device manufacturer (and SH Scientific customer), 3D-printed titanium parts showed about 90% less fatigue resistance than their milled counterparts (based on 5 million cycles at 25% of a static load over two weeks).

There’s also the matter of oxidation, which poses both mechanical and health risks.

The good news is that one well-established process can address both issues.

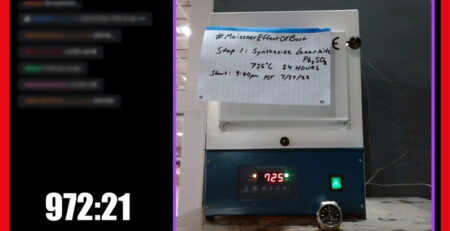

Heat Treatment for 3D-Printed Titanium Parts

Heat treatment strengthens bonds within 3DP titanium products. This renders them resilient, oxidation-free, and fit for delicate applications. (It also improves thermal efficiency and prevents carburization.)

Like all metal powders, titanium is highly prone to oxidation, so heat treatment requires a high-vacuum environment of 10-5 torr. It’s impossible to overstate the importance of consistent vacuum conditions, since virtually any oxygen presence will lead to oxidation.

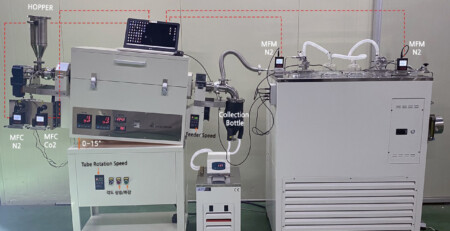

Metal Injection Molding

MIM involves a polymer binder (to render the feedstock injectable) and a release agent (to prevent the sample from adhering to its mold).

But finished goods shouldn’t contain either one.

To that end, “green” parts fresh out of the mold are debinded at temperatures up to 1100° C.

The resulting “brown” part is free of binders, but still coated in the residue of the release agent. This is removed through sintering at up to 1500° C.

Debinding and sintering are both sensitive to oxidation, so they require a controlled atmosphere (typically argon or nitrogen) and vacuum conditions.

SH Scientific’s High Vacuum Pump System

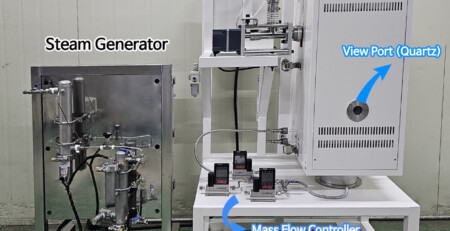

SH Scientific’s high vacuum system uses a two-stage pump to achieve pressures on the order of 10-3 to 10-7 torr.

A stage-one oil pump acts as a pre-vacuum for a stage-two diffusion pump, all coordinated by a programmable-logic controller (PLC). Oil-free alternatives are also available, but not generally needed for 3DP or MIM products.

Our pump system facilitates total atmospheric control even at extreme temperatures. Most customers purchase it as part of a turn-key furnace package, but it’s easily connected to other equipment (like certain SH tube furnaces, muffle furnaces, and drying ovens).

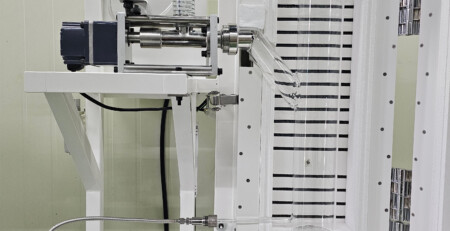

High vacuum tube furnaces

A tube furnace is the most precise and highest-heat option for smaller samples. Turn-key packages include:

- Tube furnace (choice of 1200°–1800° C max temp., ø 300–600 mm, 1–3 hot zones, and quartz or other tube)

- High vacuum pump (low-noise option available)

- Dedicated cold trap bath (condenser/chiller) and air compressor

- Gas flow package (digital mass flow controller and back pressure regulator)

Performance is equal to that of well-known manufacturers, but at a significantly lower price.

High vacuum muffle furnaces

Muffle furnaces offer terrific capacity for their price. They’re often the only choice for bulkier items.

However, their shape limits atmospheric control. Due to the non-crossing streamlines phenomenon, it’s impossible to completely flush oxygen out of a muffle chamber.

We’ve added a high vacuum pump to provide the non-oxidizing environment that previously required a tube furnace.

The result is our first-of-its-kind vacuum muffle furnace: a cost-effective solution for large yet delicate samples.

Our turn-key packages include:

- Muffle furnace (choice of 1200°–1800° C max temp., 1.5–31 L capacity, and quartz or other chamber)

- High vacuum pump (low-noise option available)

- Dedicated cold trap bath (condenser/chiller) and air compressor

- Gas flow package (digital mass flow controller and back pressure regulator)

Common questions about high vacuum furnaces

Is a vacuum tube furnace or vacuum muffle furnace appropriate for my lab?

Vacuum tube furnaces offer the absolute highest operating temperatures and atmospheric control. However, sample size is limited. Tube diameters greater than 600 mm are available, but they’re cost-prohibitive for some facilities.

Vacuum muffle furnaces allow for bulky samples. They’re technically simpler to build, which means greater capacity at a lower price. With our high vacuum pump system, atmospheric control rivals that of a tube furnace for most applications.

What are the applications of high vacuum tube furnaces?

High vacuum tube furnaces are ideal for thermal treatment of small samples that oxidize easily. That includes not only 3D printing and metal injection molding (as discussed here), but exceedingly delicate scenarios like semiconductor manufacturing and battery research.

High vacuum tube furnaces are also appropriate for organic materials analysis, medical research, materials science, general-purpose academic use, etc.

What are some other types of furnaces?

Other types of furnaces in the SH Scientific line include:

- Tube furnace: for relatively small samples that require extreme heat and/or the most exacting atmospheric control.

- Muffle furnace: more cost-effective choice for general use, especially with bulky samples.

- Vacuum muffle furnace: an alternative to vacuum tube furnaces for oxygen-free treatment of larger items (unique to SH Scientific).

- Quartz-chamber vacuum muffle furnace: provides cleanroom-like conditions for large, oxidation-prone samples.

All the above are used in both R&D and manufacturing/production settings.

Why Choose SH Scientific?

Every SH Scientific product is built in Korea and sold and supported from the US. Thanks to in-house engineering and design teams, customization is virtually unlimited—and often more cost-effective than expected.

We’re proud to equip teams that are using 3DP and MIM to redefine possibilities in aerospace, medical equipment, and beyond.

Through years of iteration and close collaboration with customers, we’ve earned the trust of institutions like the NIST, the USDA, prominent research universities, and a plethora of regional and local agencies.

Please reach out to our US sales office for help with more technical information, custom requests, or further details on our company and purchasing process.