Our Clients

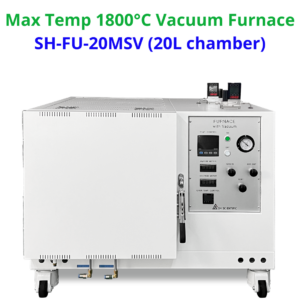

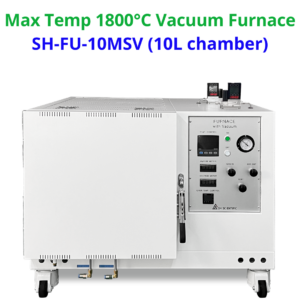

18.7MHV – 1500°C – SH Vacuum Muffle Furnace

$31,560

- Harmful gas & fume removal protects laboratory air quality

- Three-stage filtration system. Pre-filter, HEPA filter and VOC filter

- Adjustable airflow. 10 levels of air intake and exhaust volume adjustment

- Ductless operation

- (Optional) Testo 300 Combustion Gas Analyzer for Monitoring Oxygen-free atmosphere inside the chamber or tube and measure combustion gas and synthetic gas components – Contact us for available options

- (Optional) Laboratory Gas-Drying Unit by Drierite™ with Connector

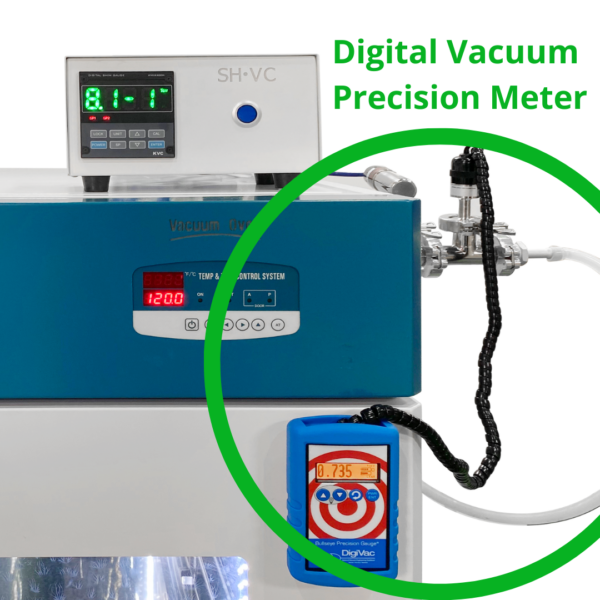

- (Optional) Digital Vacuum Precision Meter by DigiVac

Also available in 4.5 liter capacity.

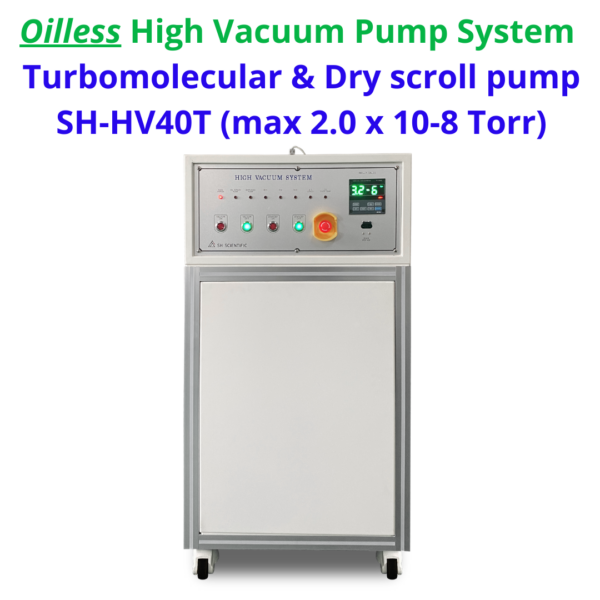

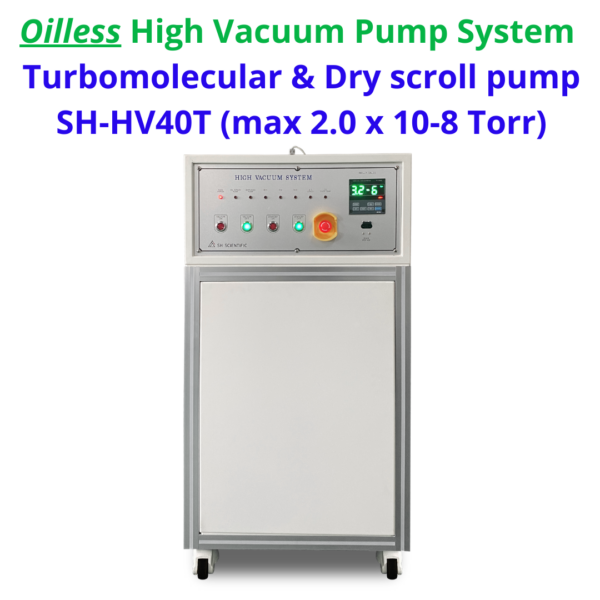

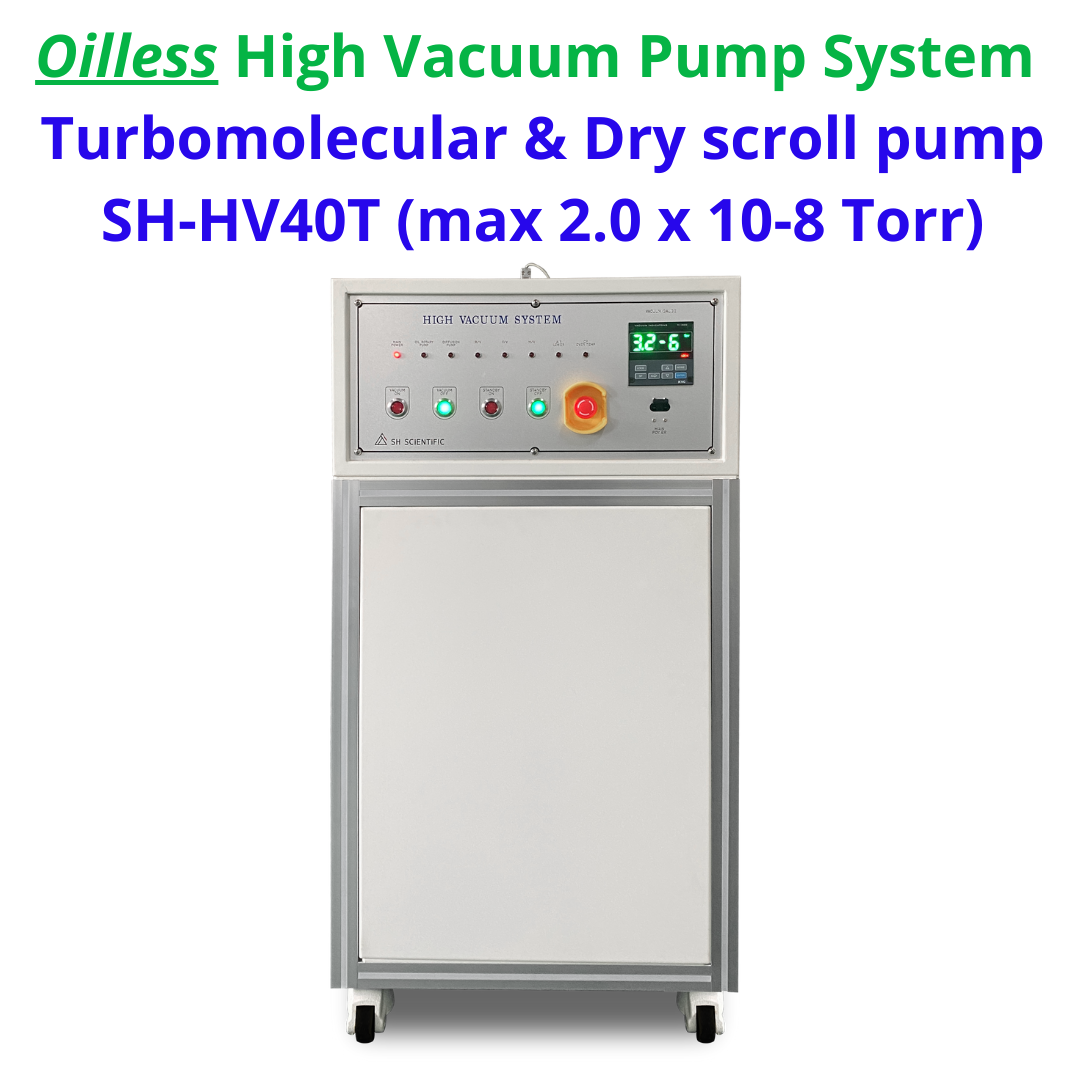

- Creating non-oxidation atmosphere thanks to inert gas full saturation with vacuum. LOW NOISE vacuum pump is available as option.

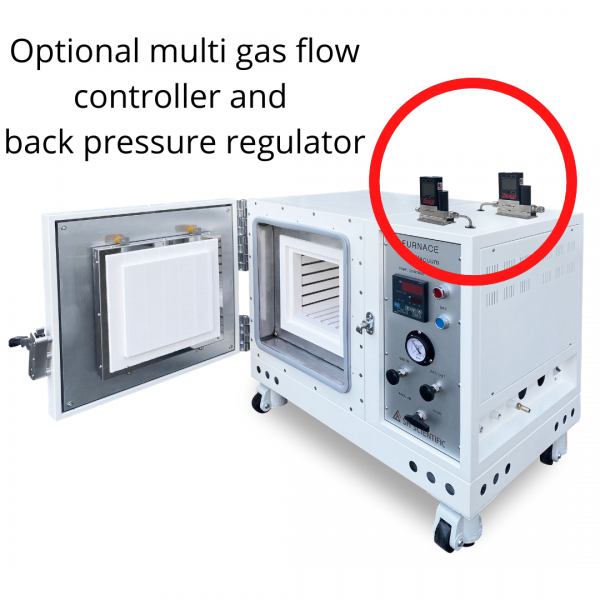

- Adding optional digital mass flow controller and back pressure regulator will produce the purest result with zero oxidation. SH Scientific’s unique innovative configuration!

- Creating your multiple atmospheric environment (burning in air, purging air and pulling vacuum, flowing inert gas and sintering)

- No limitation on materials sizes compared to the ones with tube furnace

- Support hardening, annealing, tempering, brazing and sintering with or without vacuum

- Vacuum heat treating and vacuum brazing

- Recommended ideal running temperature is below 1350°C

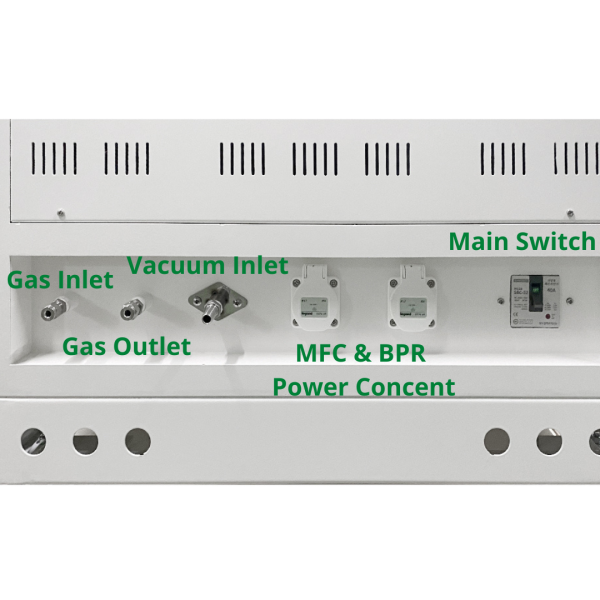

- Vacuum close and vent valve

- Gas inlet/outlet ports

- Mass flow controller for 98 kinds of various gases including Argon, Nitrogen and Hydrogen. Option

- Back pressure regulator. Option

- Preventing the non-crossing streamlines phenomenon inside chamber

- Description

- Specification

- Documents

- Reviews (0)

- FAQ

Description

Description

SH Scientific’s benchtop vacuum muffle furnace ensures an oxygen-free environment for thermal treatment. It also facilitates a carbon-free atmosphere for applications like battery anode material development, metal injection molding, metallization, and sintering.

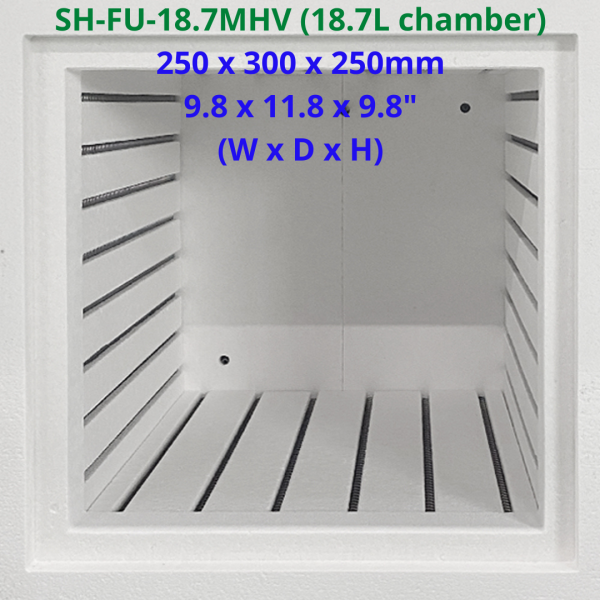

Unlike narrower tube furnaces, the muffle chamber design accommodates bulky samples for more efficient, cost-effective processing.

Key Advantages

Total environmental control: An optional digital mass flow controller and back pressure regulator ensure zero oxidation for material purity.

Innovative design: Vacuum pump overcomes the non-crossing streamlines phenomenon for full inert gas saturation—even in the corners of the chamber.

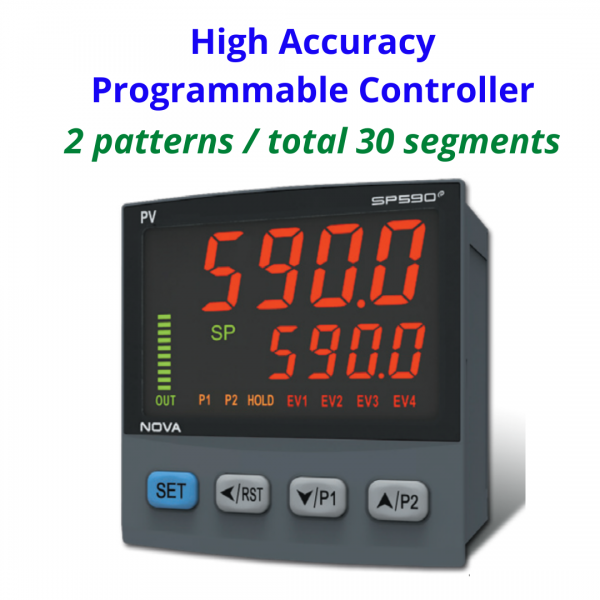

Versatile atmospheric control: Custom and pre-programmed settings allow multiple inert gas environments within a single treatment cycle (e.g., burning in air, purging air and pulling a vacuum, introducing inert gas, and then sintering).

Product Series

Each of these convenient benchtop models is built and rigorously tested in South Korea, then delivered and supported from the US.

Low-noise vacuum pumps are also available for a quieter, more pleasant, and more focused working environment.

Need something we haven’t listed here? Reach out to share your requirements and talk through more customized offerings.

Specification

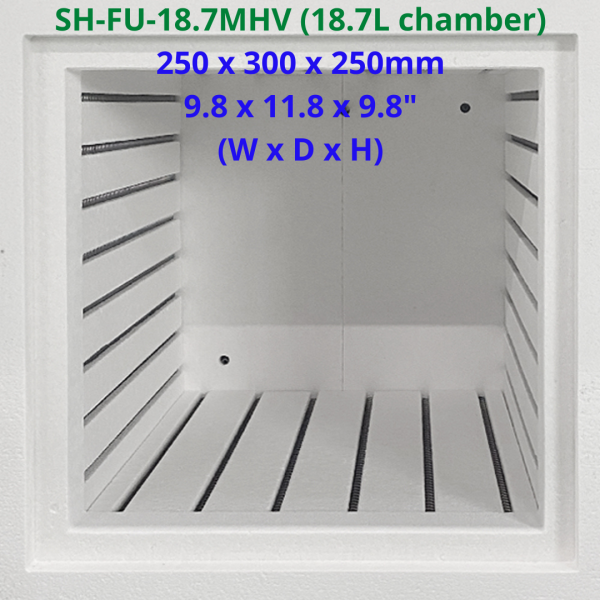

| Model | SH-FU-4.5MHV | SH-FU-18.7MHV |

|---|---|---|

| Max temperature | 1500°C | 1500°C |

| Continuous running temperature | 1350°C | 1350°C |

| Chamber volume | 4.5liters | 18.7liters |

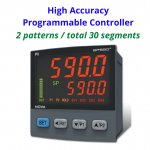

| Controller | SP590 programmable controller | SP590 programmable controller |

| Heater | 3.3kW | 10.0kW |

| Sensor | R type | R type |

| Heating element | SIC | SIC |

| Insulation | Ceramic board & wool (ceramic fiber) | Ceramic board & wool (ceramic fiber) |

| Chamber size | 150x200x150mm | 250x300x250mm |

| External size | 630x590x830mm | 1050x900x940mm |

| Option | Digital vacuum meter | Digital vacuum meter |

| Mass flow controller | Mass flow controller | |

| Back pressure regulator | Back pressure regulator | |

| Power supply | 220V, 50/60Hz, 1p, 15A | 220V, 50/60Hz, 3p, 25A

380V, 50/60Hz, 3p, 15A |

Documents

Reviews (0)

Only logged in customers who have purchased this product may leave a review.

FAQ

Content missing

Reviews

There are no reviews yet.