Our Clients

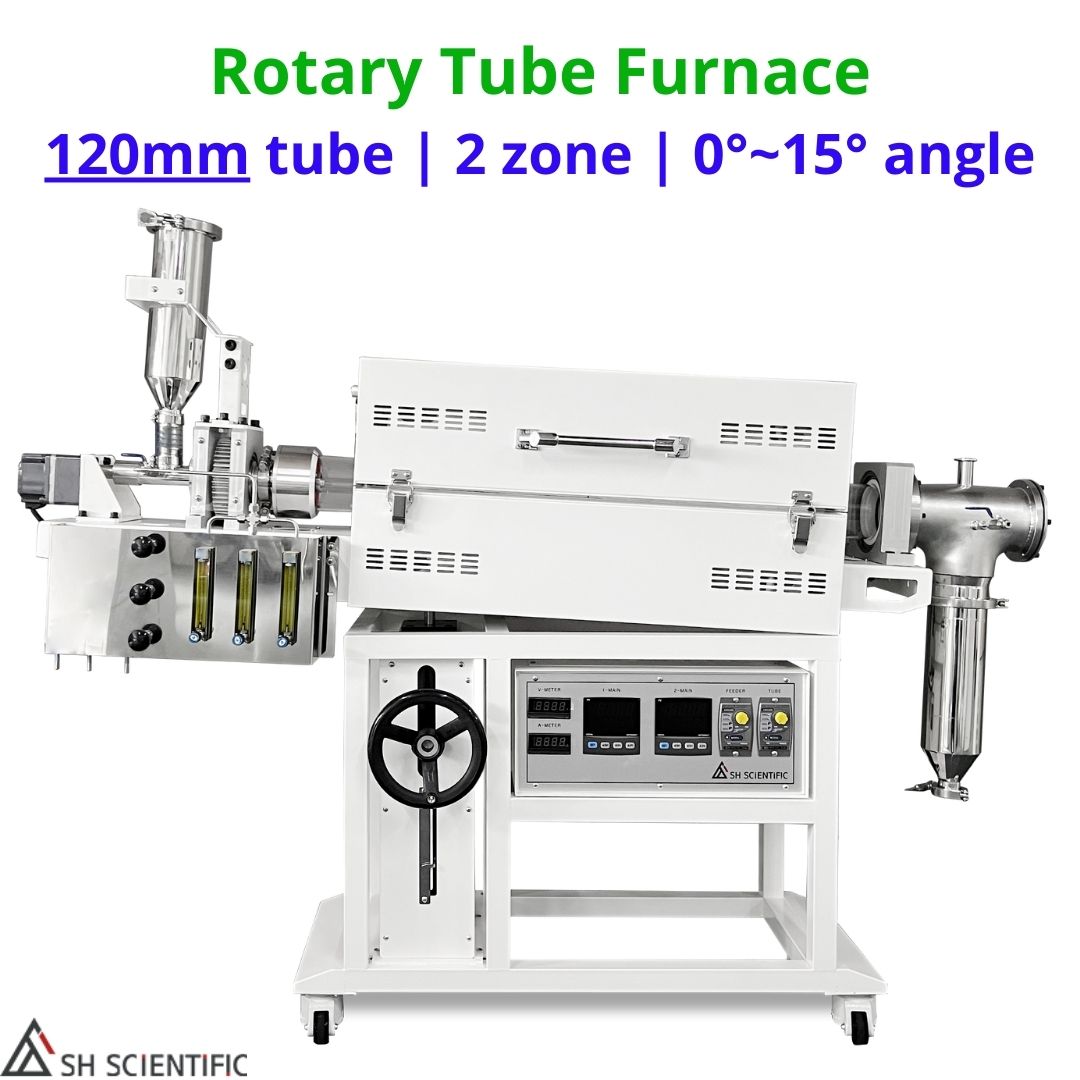

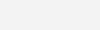

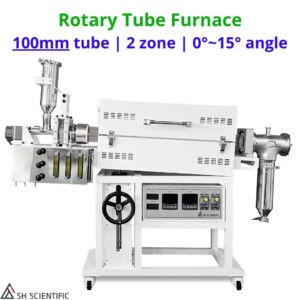

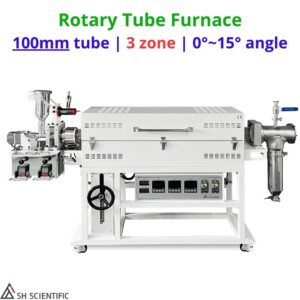

120RTG – 2 zone – 1200°C – SH Rotary Tube Furnace (Lab Scale Rotary Kiln)

$40,100

Looking for a laboratory-scale rotary kiln for continuous pyrolysis and other highly controlled heat processing? SH Scientific offers top-of-the-line rotary tube furnaces designed for a multitude of applications, including food waste processing, biochar production, biomass processing, and more.

- Rotary tube furnace with hinged door. Lab scale rotary kiln

- 120mm (4.7″) tube diameter

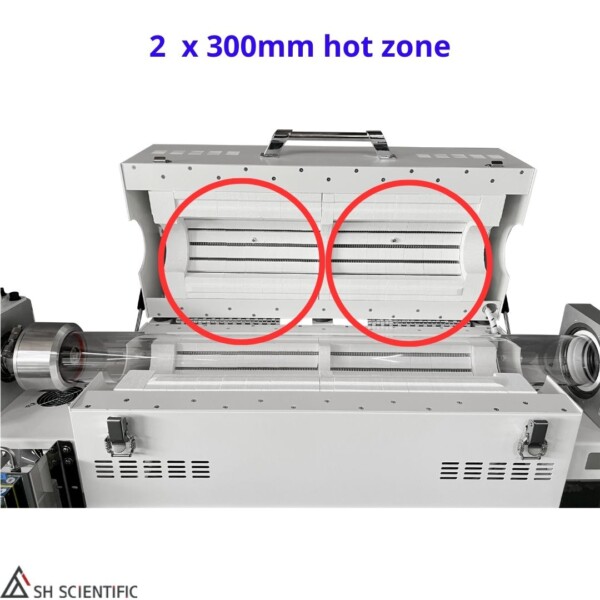

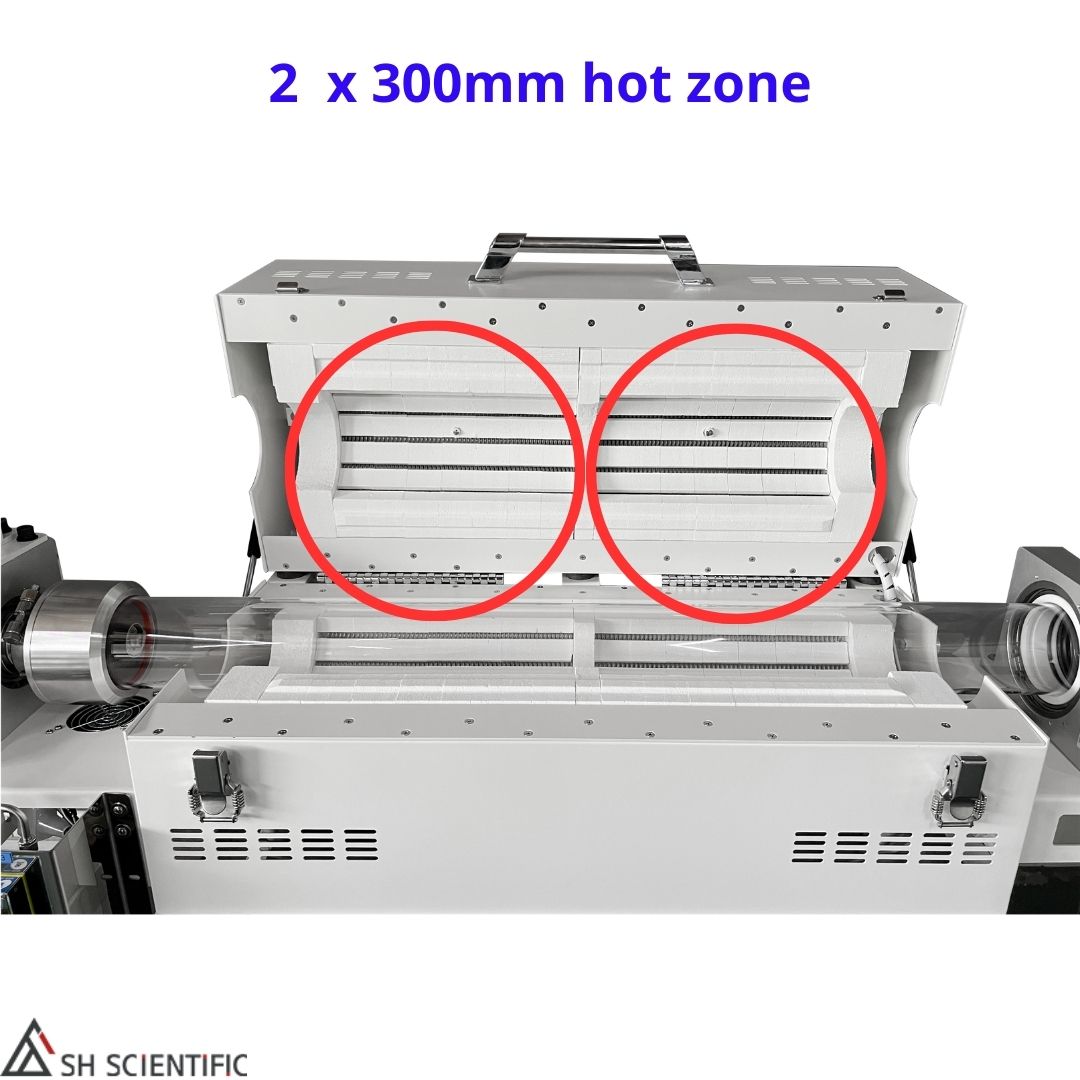

- 2 x 300mm (12″) hot zone, total 600mm (24″) hot zone

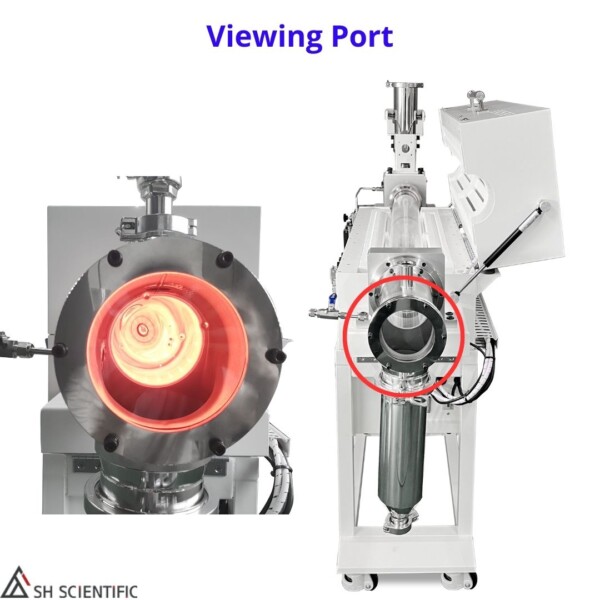

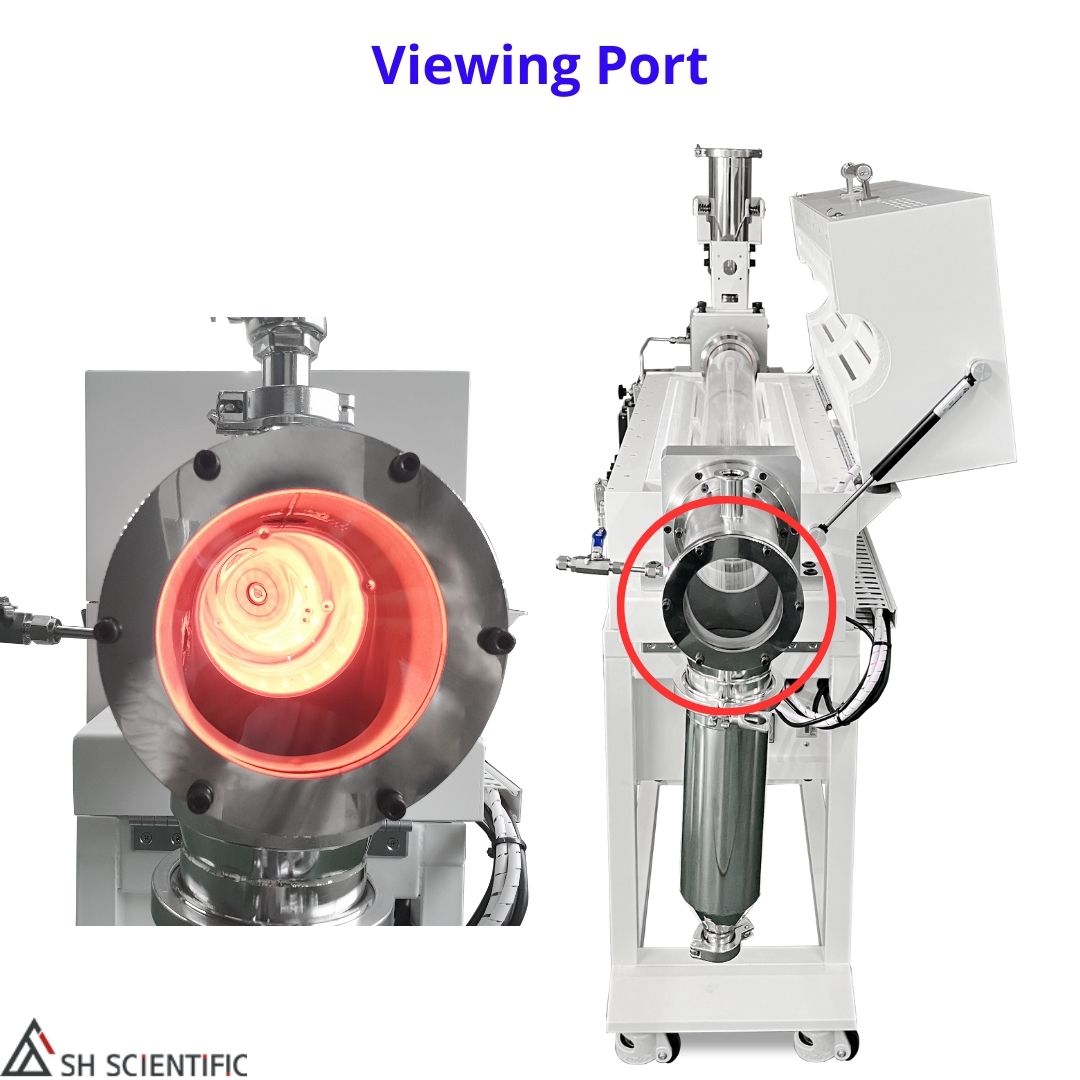

- Monitoring view port (quartz window)

- 1/4″ inert gas in/out port & KF25 outgassing port

- Easy to assemble, easy to replace tube and perfect vacuum sealing

- Optional hopper knocker for high viscosity organic material such as food waste and animal excretions

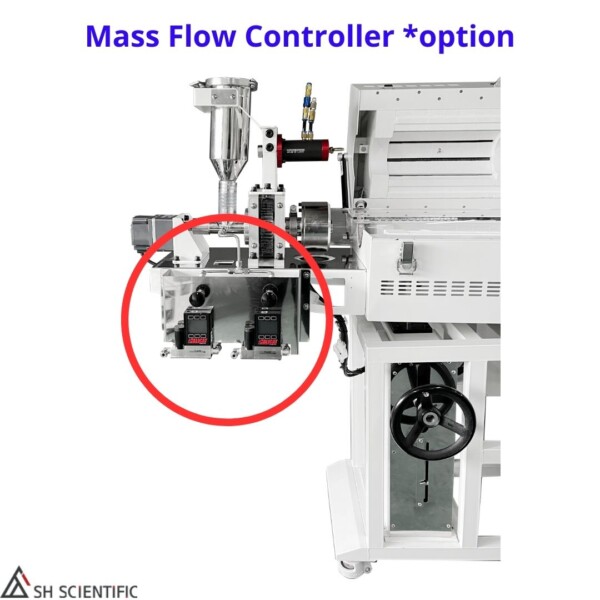

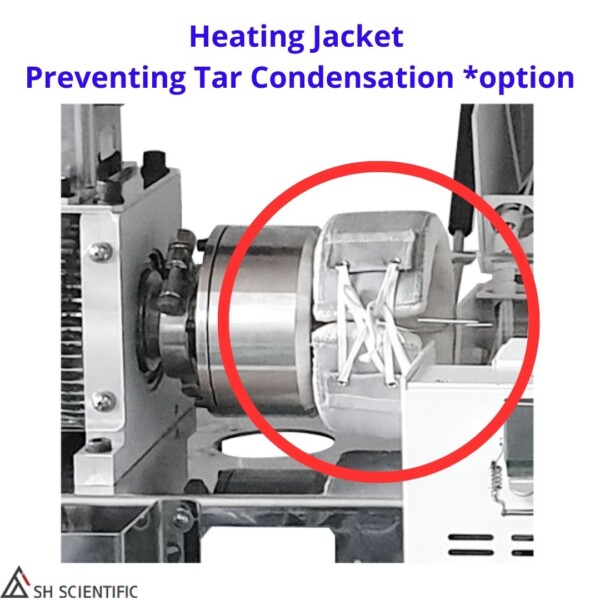

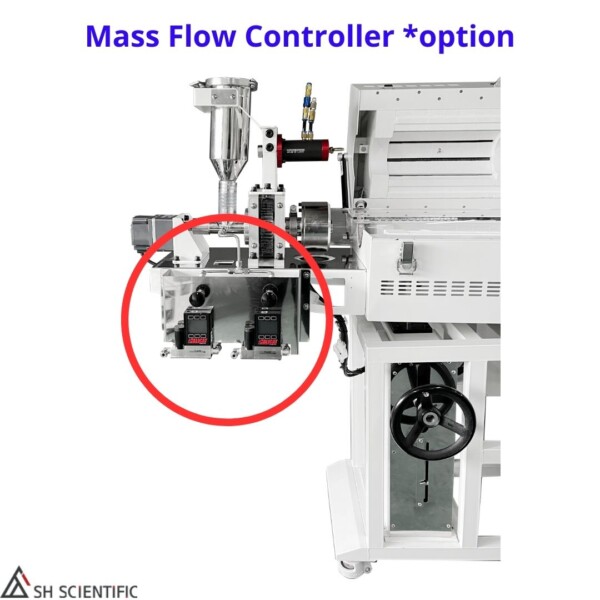

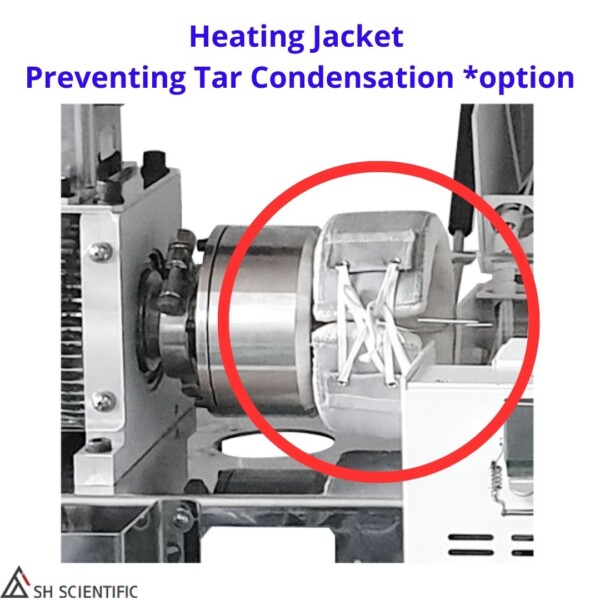

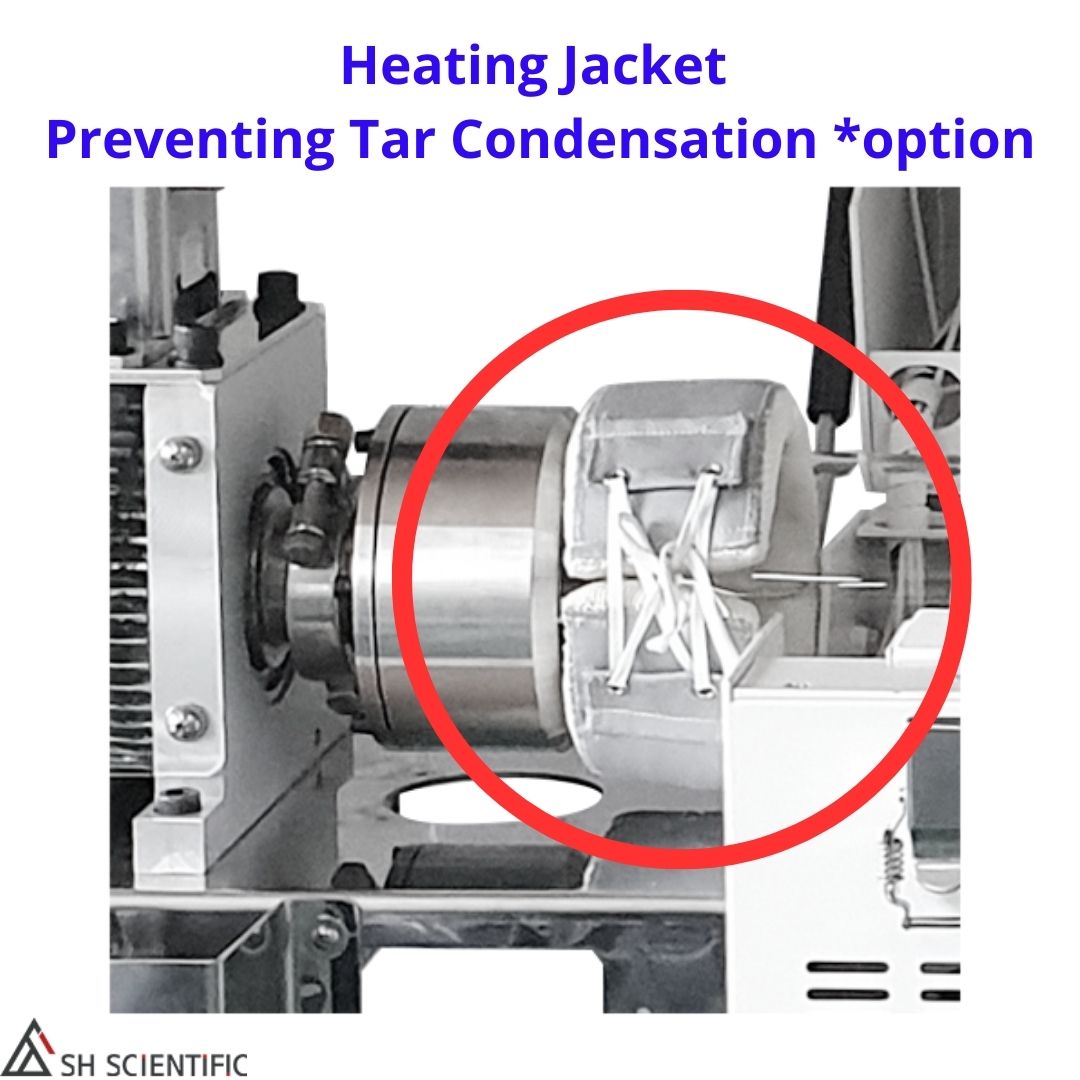

- Optional heating jackets preventing tar condensation

- Double housing and low surface temperature (29~30°C at 800°C)

- Max temperature 1200°C. Recommended ideal running temperature is 1000°C or below.

- Great durability thanks to Kanthal-A heating element

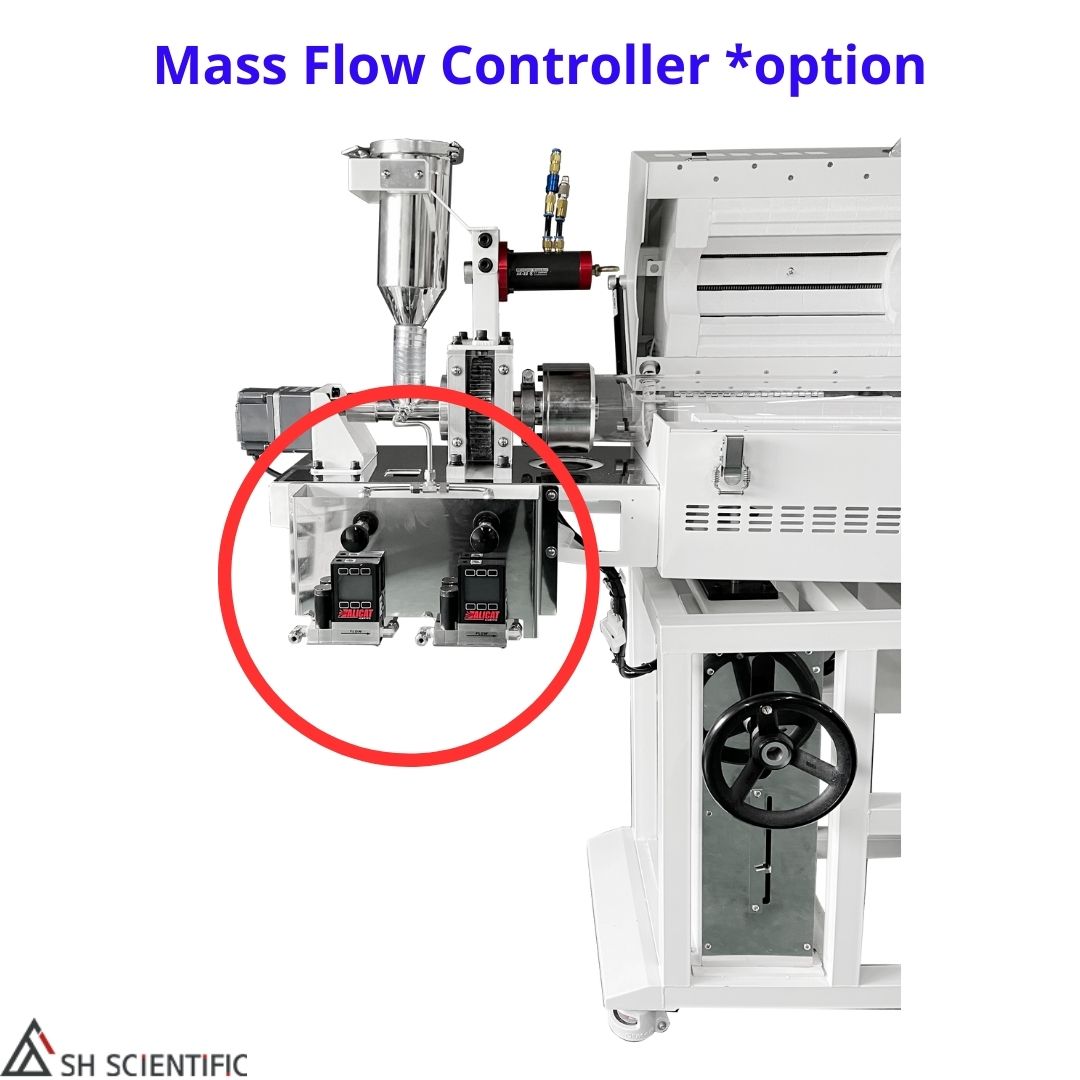

- Suitable for gas exchange experiment

- Light weight and prompt heat up thanks to ceramic insulation

- Convenient design for sample loading

- Built in programmable controller. 2 patterns and 15 segment/pattern. Total 30 segments

- Built in over temp protector

- SSR operation and built in programmable controller provides low noise operation and precise temp control (+/-1°C)

- Description

- Specification

- Documents

- Reviews (0)

- FAQ

Description

Description

SH Scientific’s rotary tube furnaces are the pinnacle of continuous pyrolysis technology.

These laboratory-scale rotary kilns suit a wide range of applications. Every device is engineered in South Korea by our in-house team, offering world-class efficiency and extensive customization at competitive prices.

High Performance for Wide-Ranging Uses

Right now, customers use our rotary tube furnace in scenarios as varied as:

- Food waste, biochar, and biomass processing

- Battery waste recycling

- High-purity battery material processing

- High-capacity silicone carbon production

- Hydrogen fuel battery production

- General oxidation, reduction, and biomass carbonization

Innovative Design for Uniform Processing

Feed powder-type materials continuously with controlled speed for uniform heat treatment under various atmospheres (oxidation and reduction). Our design supports both batch and continuous processes, with the dwelling time adjustable through the incline angle, tube rotation speed, and material flow/agitation properties.

- Feeding and receiving system: Samples flow smoothly from the feeding tank at the upper end into the receiving vessel at the lower end.

- Prevention of tar condensation: Heating jackets at both ends maintain temperature, preventing tar buildup.

- Anti-clogging features: A hopper knocker in the feeder keeps viscous materials flowing steadily.

Standard Models

- 2 heating zones: Max 1200°C with 100 mm tube (SH-FU-100RTG-2) or 120 mm tube (SH-FU-120RTG-2).

- 3 heating zones: Max 1200°C with 100 mm (SH-FU-100RTG-3) or 120 mm tube (SH-FU-100RTG-3).

Tubes from 200 mm to as large as 800 mm in diameter are available for use as an industrial-scale rotary kiln.

Every single furnace—regardless of its specs or customization—undergoes rigorous testing. We verify its rotation, heating, and even vacuum retention with inert gas injection.

SH Scientific is your partner for advanced rotary tube furnaces that deliver years of reliable results. Need something we haven’t listed here? Reach out to share your requirements and talk through more customized offerings.

Specification

| Model | SH-FU-100RTG-2 | SH-FU-120RTG-2 |

| Max Temp | 1200℃ (2192℉) | |

| Temp Controller | Programmable Controller (SP590) | |

| Sensor | K type | |

| Hot Zone | 600mm (24in) 300mm(12in) x 2 Zone |

|

| Applicable Tube Diameter & length | 100 Φ x 1500 mm | 120 Φ x 1500 mm |

| Dimension (W x D x H) | 2025 x 510 x 1345mm | 2025 x 530 x 1545mm |

| 79.7 x 20.1 x 53.0″ | 79.7 x 20.8 x 60.8” | |

| Heater Capa | 4kW | 5kW | |

| Heating Jacking (option) | Max 400℃ | |

| Feeding Vessel | 2L (Stainless Steel) | |

| Receiving Vessel | 2L (Stainless Steel) | |

| Tube Rotation Speed | 0.7 ~ 14 RPM | |

| Feeder speed | 0.5 ~ 10 RPM | |

| Tube Angle | 0 ~ 15˚ | |

| Heater Element | Kanthal A-1 | |

| Insulation | Ceramic Board & Wool | |

| Gas port | ¼” tube lock valve | |

| Gas Exhaust port | KF25 with ball valve | |

| Electrical Requirements | 220V, 50/60Hz, 1p, 18A | 220V, 50/60Hz, 1p, 23A |

Documents

Reviews (0)

Only logged in customers who have purchased this product may leave a review.

FAQ

Content missing

Reviews

There are no reviews yet.