100RTH – 2 zone – 1500°C – SH Rotary Tube Furnace (Lab Scale Rotary Kiln)

$55,400

Looking for max 1500°C laboratory-scale rotary kiln for continuous pyrolysis and other highly controlled heat processing? SH Scientific offers top-of-the-line rotary tube furnaces designed for a multitude of applications, including limestone sintering, low carbon cement processing, metal powder processing, biochar production, biomass processing, and more.

- Lab & pilot scale rotary kiln

- Max temperature 1500°C. Recommended ideal running temperature is 1350°C or below.

- OD 100mm (4″) alumina tube

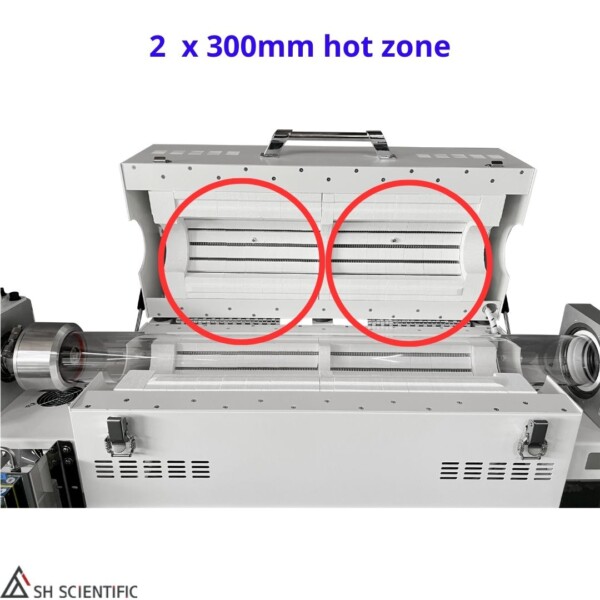

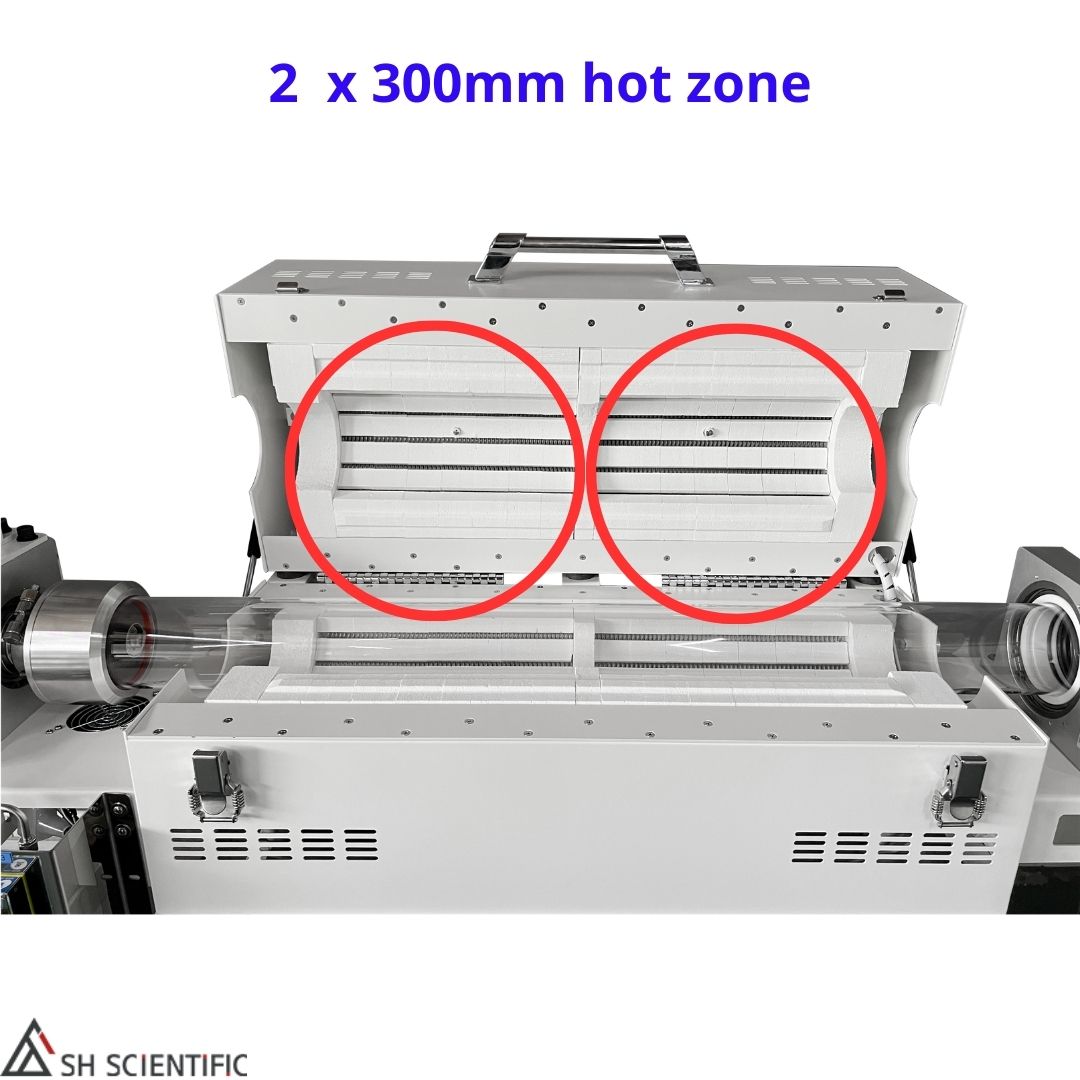

- 2 x 300mm (12″) hot zone, total 600mm (24″) heating length

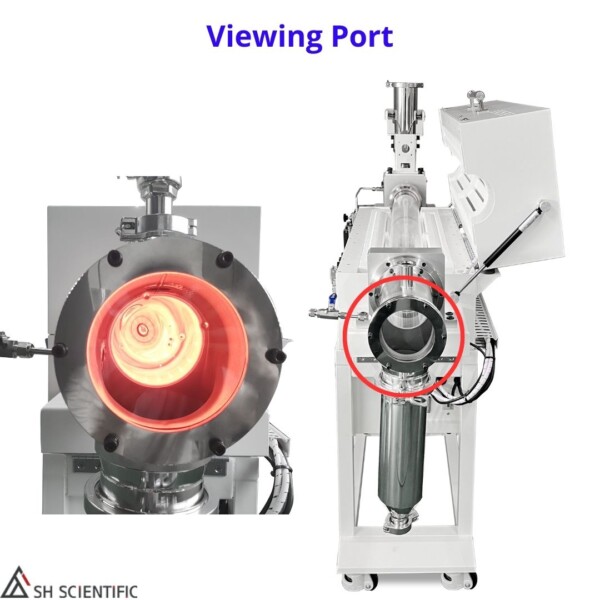

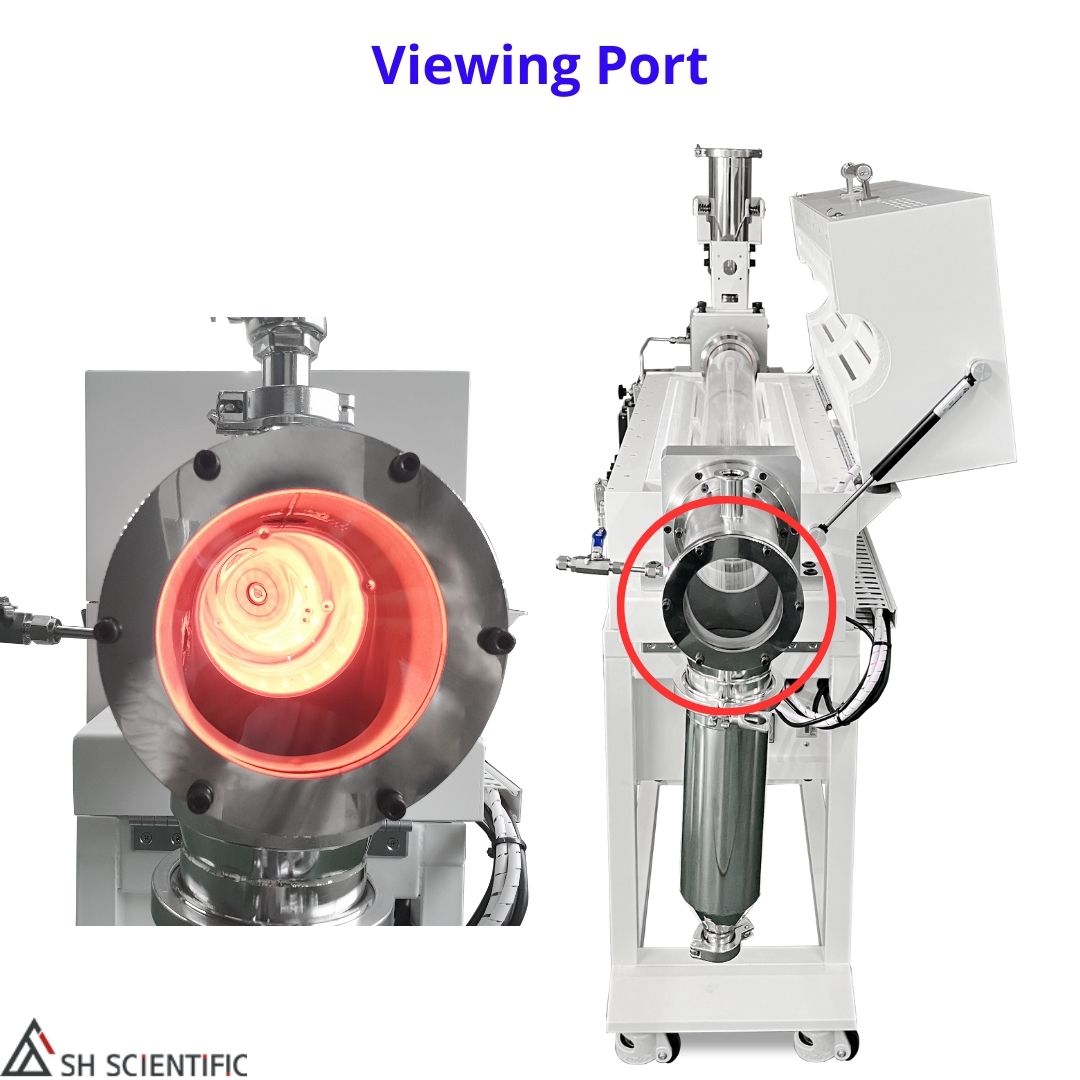

- Monitoring view port (quartz window)

- 1/4″ inert gas in/out port & KF25 outgassing port

- Easy to assemble, easy to replace tube and perfect vacuum sealing

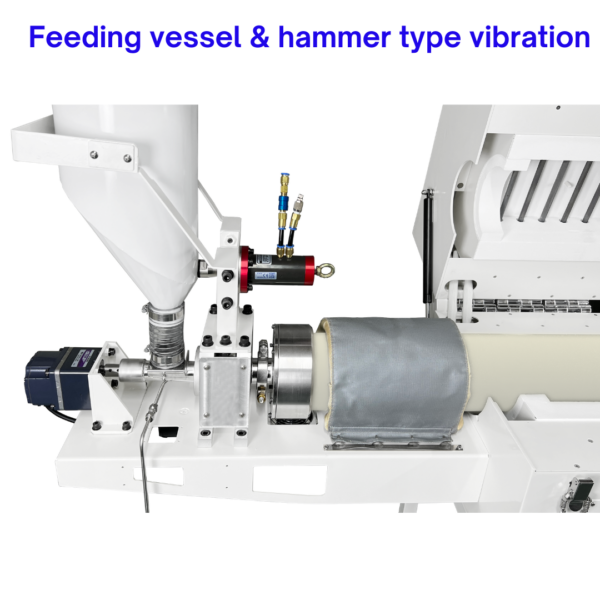

- Optional hopper knocker for high viscosity organic material such as food waste and animal excretions

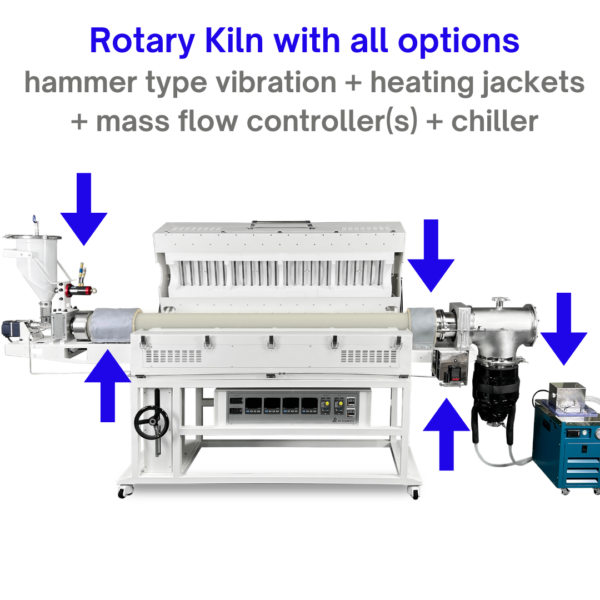

- Optional heating jackets preventing tar condensation

- Double housing and low surface temperature (29~30°C at 800°C)

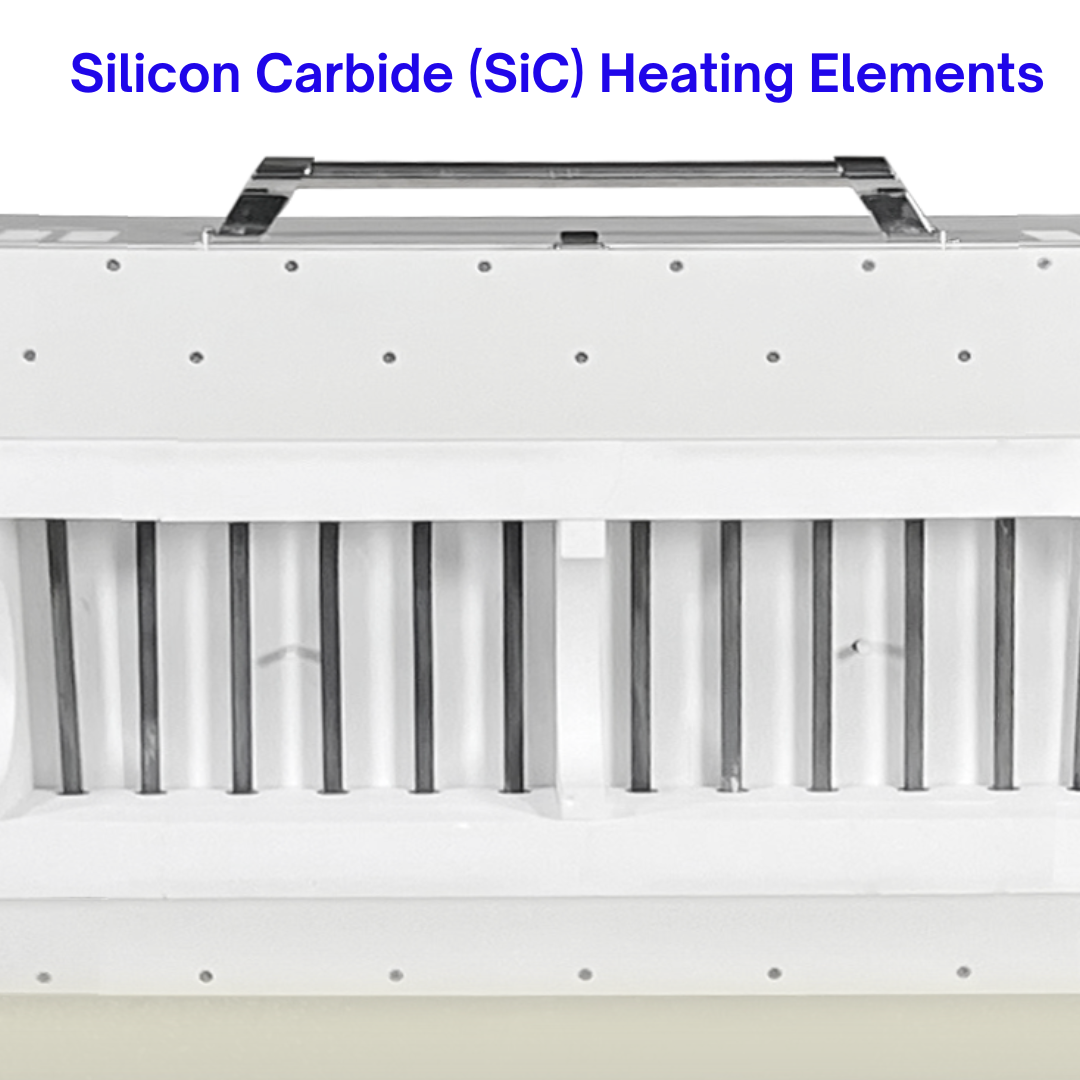

- Great durability thanks to Silicon Carbide (SiC) heating element

- Suitable for gas exchange experiment *co-current & counter-current

- Built in programmable controller. 2 patterns and 15 segment/pattern. Total 30 segments

- Built in over temp protector

- Description

- Specification

- Documents

- Reviews (0)

- FAQ

Description

Description

SH Scientific’s 1500°C Rotary Tube Furnace: Precision and Innovation for Advanced Research

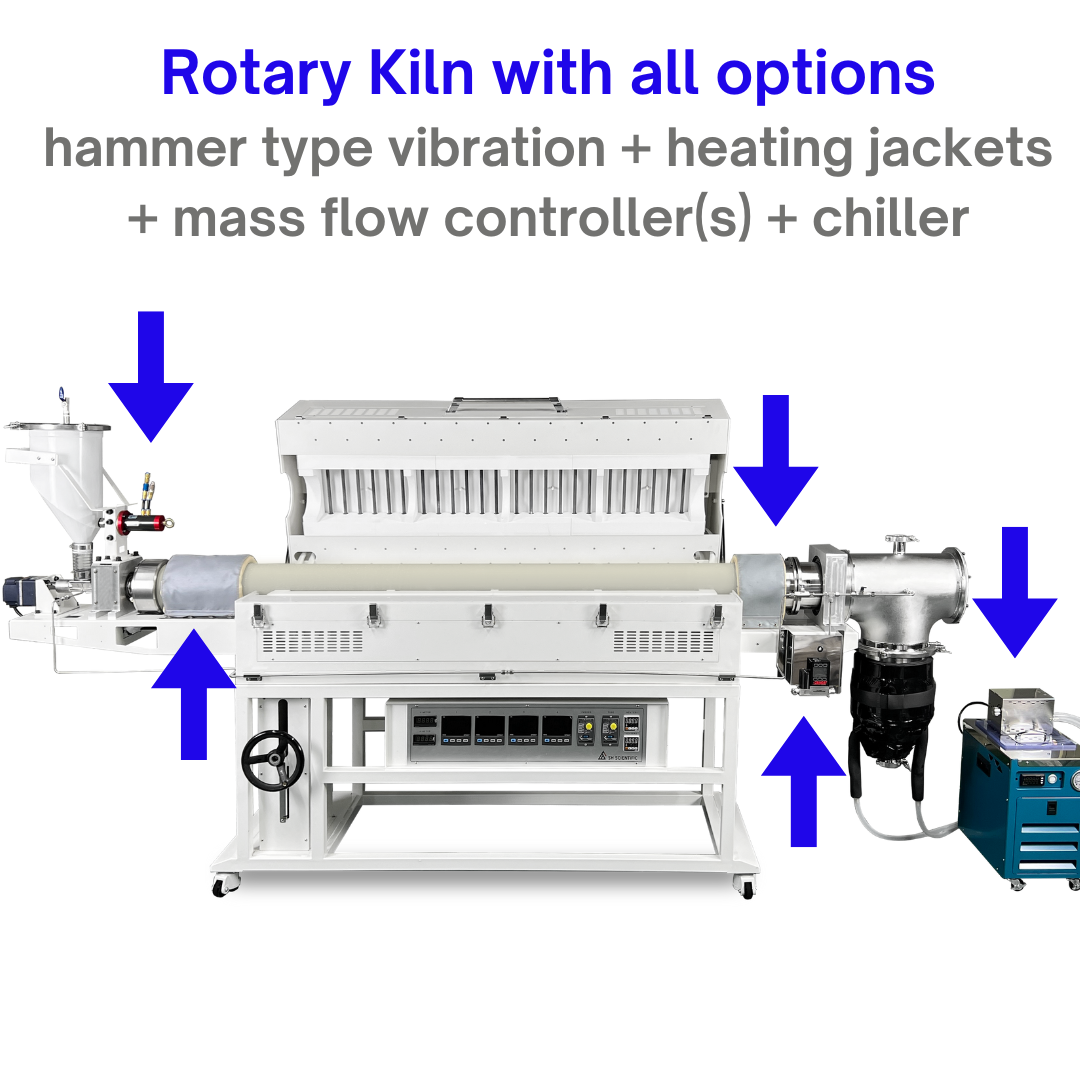

Elevate your research with SH Scientific’s 1500°C high-temperature rotary tube furnace (also known as a lab-scale rotary kiln). Engineered for laboratory and pilot-scale applications, this advanced equipment delivers exceptional efficiency, reliability, and customization, making it a top choice for researchers—particularly in cement research and calcined clay production.

Key Applications

- Limestone sintering, Cement Research & Calcined Clay Production: Perfect for low-carbon cement processing and producing high-quality calcined clay.

- Biochar and biomass conversion

- Battery waste recycling and high-purity battery material synthesis

- Hydrogen fuel cell production

- High-capacity silicone carbon production

- General oxidation, reduction, and carbonization experiments

Innovative Features for Reliable Performance

- Precise Heat Treatment: Uniform heating under oxidation or reduction atmospheres with adjustable tube rotation speed, incline angle, and material flow.

- Continuous & Batch Processing: Flexible configurations tailored to experimental needs.

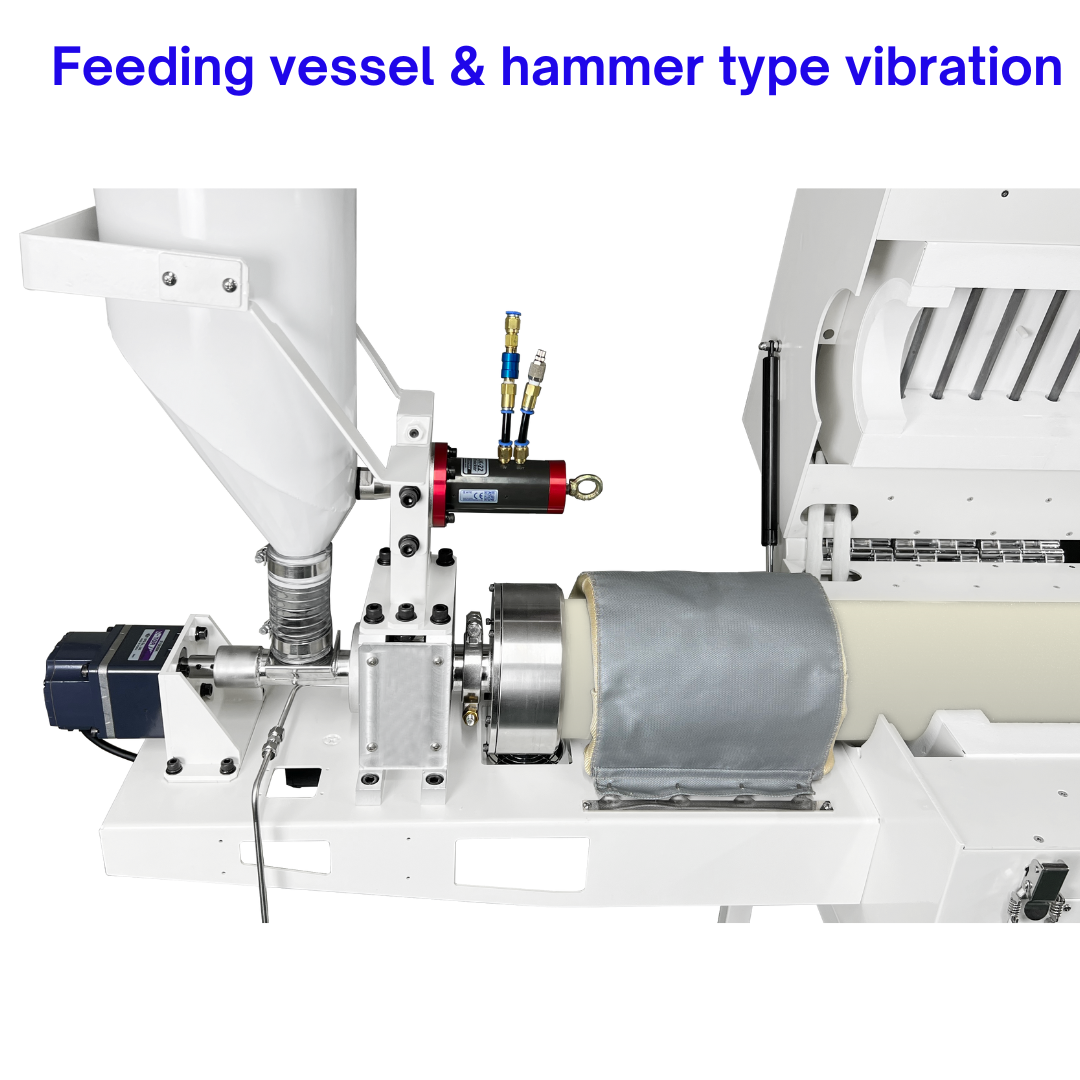

- Efficient Feeding & Receiving System: Smooth material transfer from the feeding tank to the receiving vessel ensures uninterrupted operation.

- Prevention of Tar Condensation: Heating jackets at critical points avoid tar buildup during pyrolysis.

- Anti-Clogging Mechanism: Optional hopper knocker maintain steady flow of viscous materials.

Technical Highlights

- Max Temperature: 1500°C (ideal operating range ≤ 1350°C).

- Tube Options: Standard models with 100mm or 120mm OD alumina tubes; industrial options available up to 800mm diameter.

- Heating Zones: Configurations include 2-zone (600mm) or 3-zone (900mm) for enhanced control.

- Gas Exchange Compatibility: Supports co-current and counter-current flow experiments.

- Programmable Controller: Up to 30 programmable segments for precise temperature control.

- Durable SiC Heating Elements: High-performance, long-lasting heating.

- Vacuum Sealing & Gas Ports: Perfect vacuum sealing with inert gas inlets/outlets and outgassing features.

- Safety & Convenience: Low surface temperature housing (29–30°C at 800°C), built-in over-temperature protection, and easy tube replacement.

Why Choose SH Scientific?

SH Scientific’s lab-scale rotary kiln is highly preferred by industries focused on cement research and calcined clay production due to its precise heat treatment capabilities and customizable features. Each furnace undergoes rigorous testing for rotation, heating, and vacuum retention to ensure optimal performance.

From standard models to fully tailored solutions, SH Scientific’s rotary tube furnaces provide the innovation and reliability required for cutting-edge research. Explore custom options and unlock your research potential today.

Specification

| Model | SH-FU-100RTH-2 | SH-FU-120RTH-2 |

| Max Temp | 1500℃ (2732℉) | |

| Temp Controller | Programmable Controller (SP590) | |

| Sensor | R type | |

| Hot Zone | 2 x 300mm(12in), total 600mm (24in) | |

| Applicable Tube Diameter & length | 100 Φ x 1480 mm | 120 Φ x 1480 mm |

| Dimension (W x D x H) | 2330 x 510 x 1345mm | 2330 x 530 x 1545mm |

| 91.7 x 20.1 x 53.0″ | 91.7 x 20.8 x 60.8” | |

| Heater Capa | TBD | TBD | |

| Heating Jacking (option) | Max 400℃ | |

| Feeding Vessel | 2L (Stainless Steel) | |

| Receiving Vessel | 2L (Stainless Steel) | |

| Tube Rotation Speed | 0.7 ~ 14 RPM | |

| Feeder speed | 0.5 ~ 10 RPM | |

| Tube Angle | 0 ~ 15˚ | |

| Heating element | Silicon Carbide (SiC) | |

| Insulation | Ceramic Board & Wool | |

| Gas port | ¼” tube lock valve | |

| Gas Exhaust port | KF25 with ball valve | |

| Electrical Requirements | 220V, 50/60Hz, 1p hardwire | 220V, 50/60Hz, 1p hardwire |

Documents

Reviews (0)

Only logged in customers who have purchased this product may leave a review.

FAQ

Content missing

Reviews

There are no reviews yet.