Our Clients

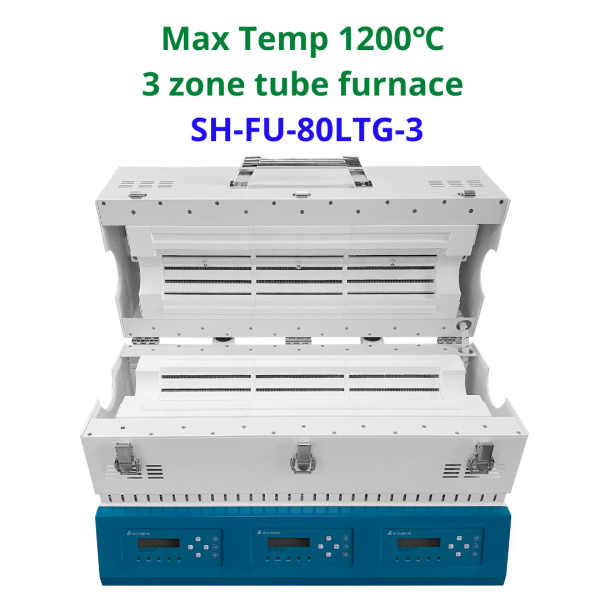

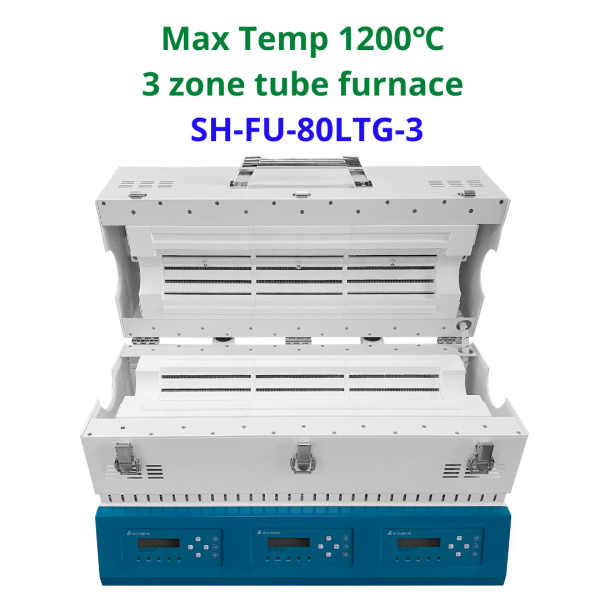

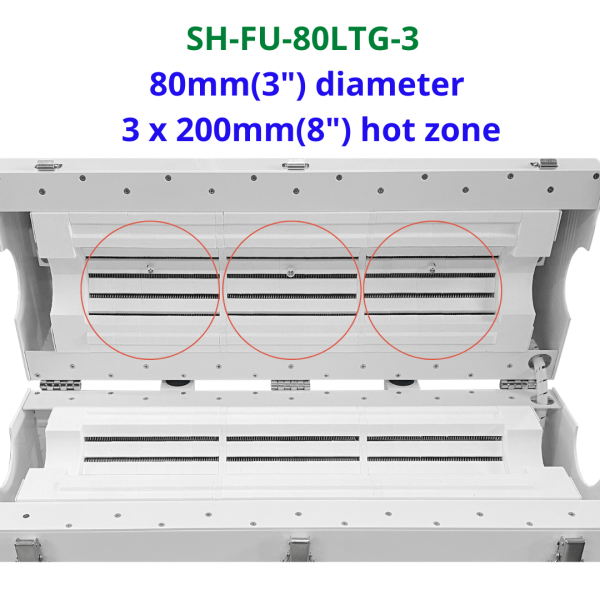

80LTG – 3 – 1200°C – SH Tube Furnace

$7,600

Also available in 50mm tube size, 100mm tube size and 120mm tube size.

- General tube furnace with hinged door

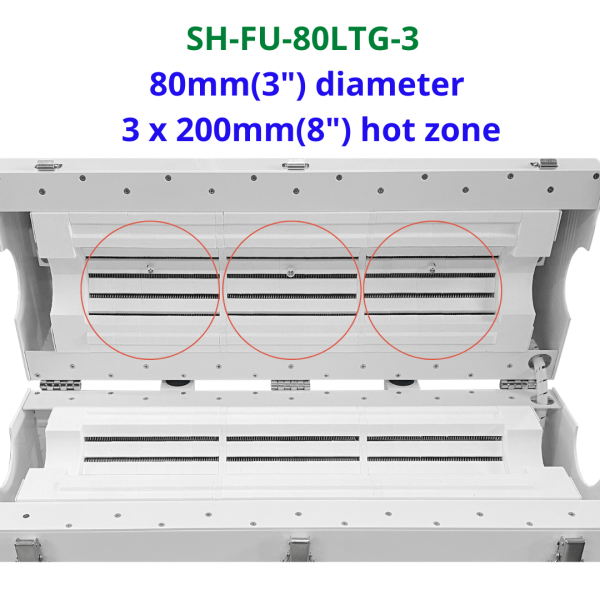

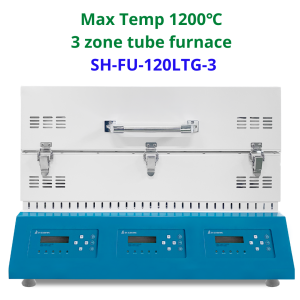

- 80mm (3″) diameter, THREE HOT ZONES, 3 x 200mm (8″), total 600mm (24″) long hot zone

- Max temperature 1200°C. Recommended ideal running temperature is 1000°C or below.

- Double housing and low surface temperature (29~30°C at 800°C)

- Great durability thanks to Kanthal heating element

- Suitable for gas exchange experiment (WG SERIES)

- Light weight and prompt heat up thanks to ceramic insulation

- Convenient design for sample loading

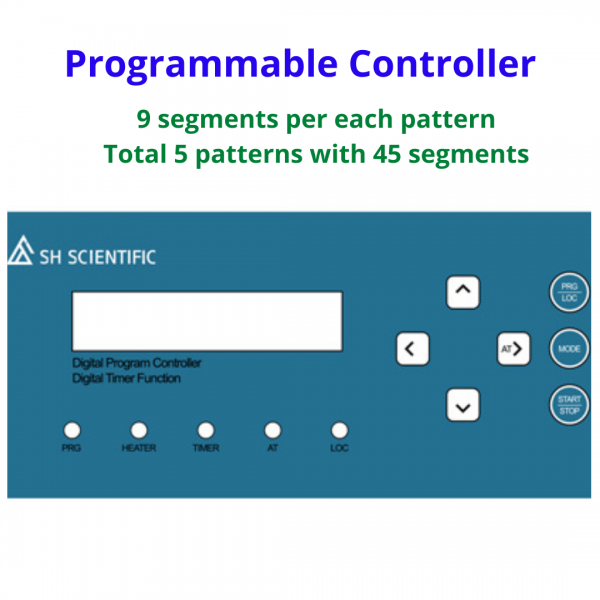

- 3 built in programmable controllers. 5 patterns and 9 segment/pattern. Total 45 segments

- Built in over temp protector

- SSR operation and built in programmable controller provides low noise operation and precise temp control (+/-1°C)

- Wide choice of applicable tube sizes and heating length. 50/80/100/120mm diameter and 300/600mm heating zone

- Wide choice of tube materials. Quartz, ceramic, alumina and alloy

- Description

- Specification

- Documents

- Reviews (0)

- FAQ

Description

Description

You are in the best place if you look for professional tube furnace selection with wanted configuration at the most reasonable prices.

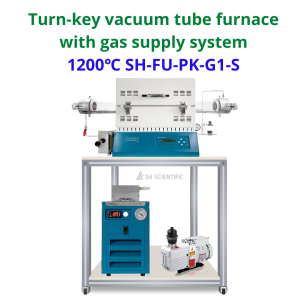

– tube furnace only

– tube furnace with gas flow management system

– tube furnace with gas flow management system bundled with vacuum pump and chiller (in short, vacuum tube furnace turnkey system)

Furnace is our specialty and you can rely on us.

Tube furnaces consist of cylindrical chambers surrounded by heating elements, which enable rapid heat up, recovery and cool down. Tube furnace is the most economical way to treat a small sample, especially where volatile materials need to be captured or atmosphere other than air is required. SH Scientific tube furnaces are designed for a range of applications with features that can include: digital programmable controllers, single hot zone or three hot zones, double-shell construction, variable density insulation and split-hinge or solid door designs to allow horizontal usage. Programmable controller enables you to perform cyclic oxidation and treatment test at ease.

These days the use of tube furnaces are more rapidly growing in the secondary battery and graphene battery, polymer composite, treatment of titanium and ceramic in 3D printing industry.

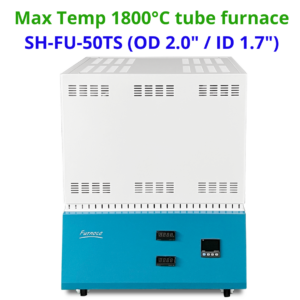

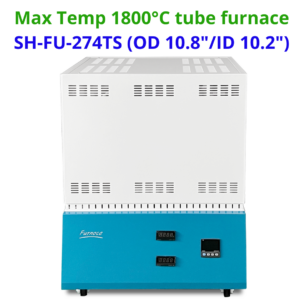

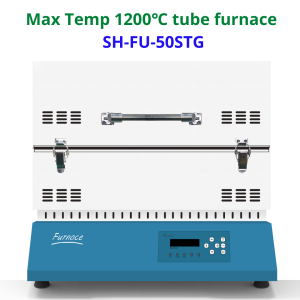

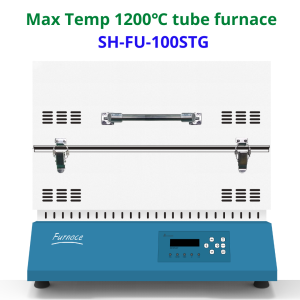

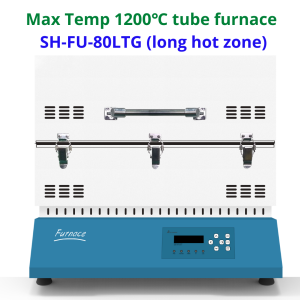

SH Scientific tube furnace STG/LTG series goes up to max 1200°C and the ideal operating temperature is 1000°C. 50mm/80mm/100mm/120mm tube diameters are standard and we can custom larger diameter tubes too.

STG hot zone is 300mm and LTG hot zone is 600mm. Both have built-in 45 steps programmable controller. Do you want to have 3 controllers with 3 hot zones? LTG-3 is the one.

Specification

| Model | SH-FU-80LTG-3 |

|---|---|

| Max Temp | 1,200°C (2,192°F) |

| Temp Controller | Programmable Controller(FC-1000) |

| Sensor | K type |

| Applicable Tube Diameter | 80 Φ |

| Heater Capa | 1.8Kw x 3 Zone = 5.4Kw |

| Dimension Hot Zone | 200mm x 3 Hot Zone = Length 600 mm |

| Dimension External (W×D×H ) |

850x400x570mm 33.46×15.75×22.44″ |

| Weight | 56Kg |

| Heater Element | Kanthal A-1 |

| Insulation | Ceramic Board & Wool |

| Electrical Requirements 220V, 50/60Hz, 1Φ |

23.5 A |

| Cat. No. 50Hz(60Hz) | FU50LTG1-220 |

Documents

Reviews (0)

Only logged in customers who have purchased this product may leave a review.

FAQ

Content missing

Reviews

There are no reviews yet.