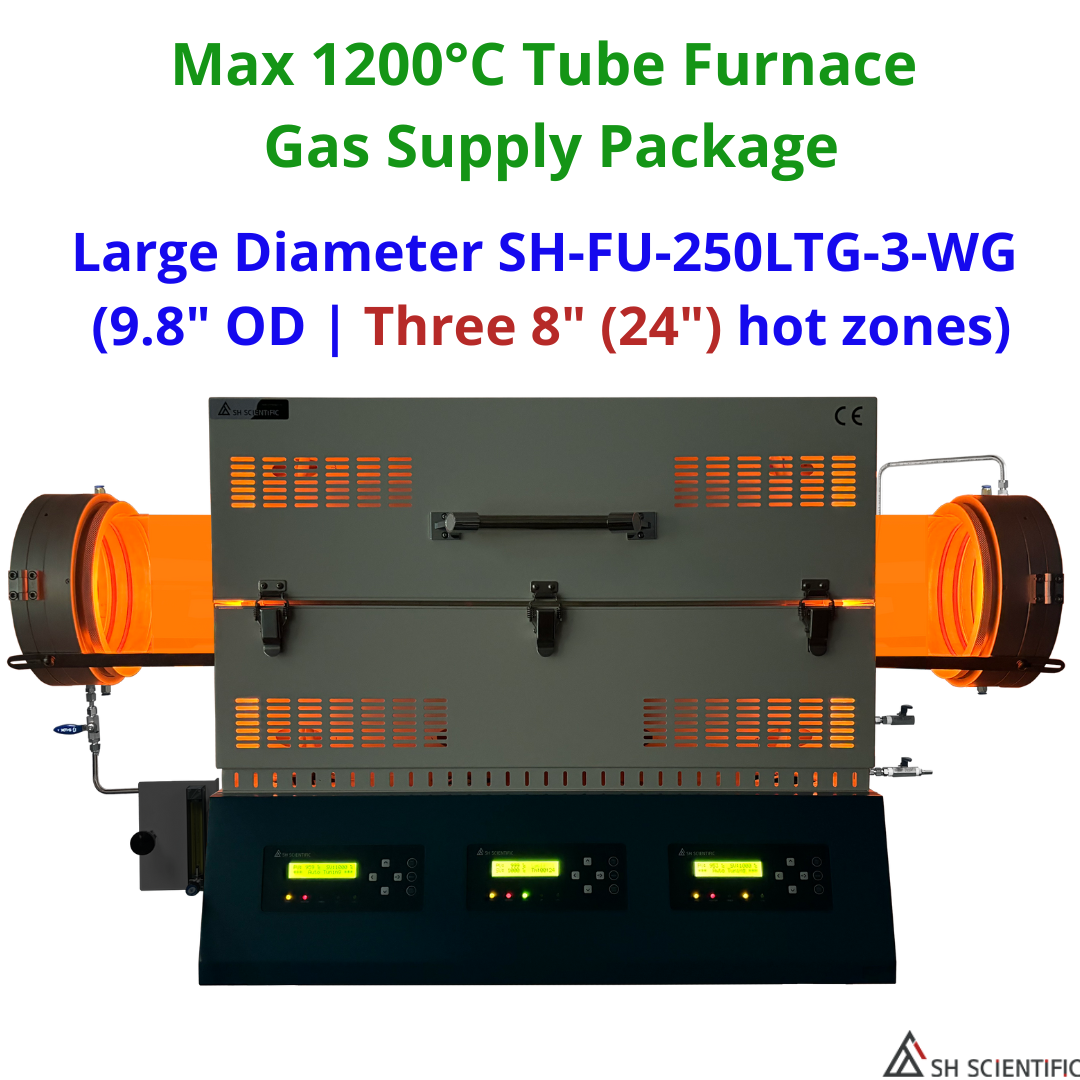

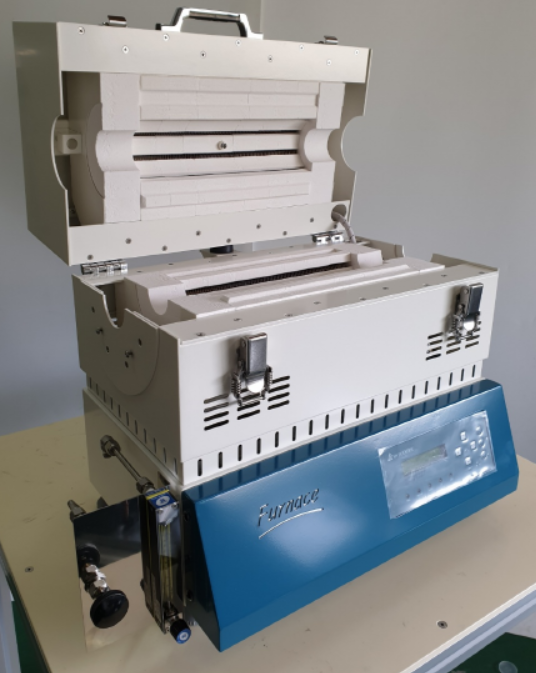

250LTG–3–WG – 1200°C – Large Diameter 3 Zone Tube Furnace w/ Gas Supply System

$34,770

- Harmful gas & fume removal protects laboratory air quality

- Three-stage filtration system. Pre-filter, HEPA filter and VOC filter

- Adjustable airflow. 10 levels of air intake and exhaust volume adjustment

- Ductless operation

- (Optional) Testo 300 Combustion Gas Analyzer for Monitoring Oxygen-free atmosphere inside the chamber or tube and measure combustion gas and synthetic gas components – Contact us for available options

- (Optional) Laboratory Gas-Drying Unit by Drierite™ with Connector

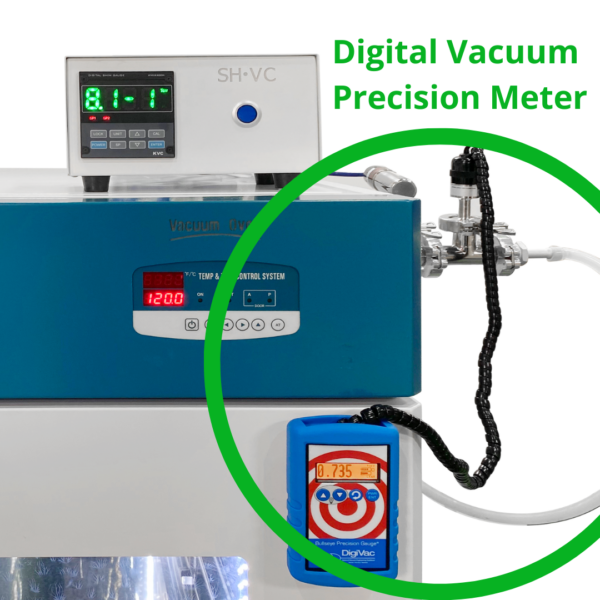

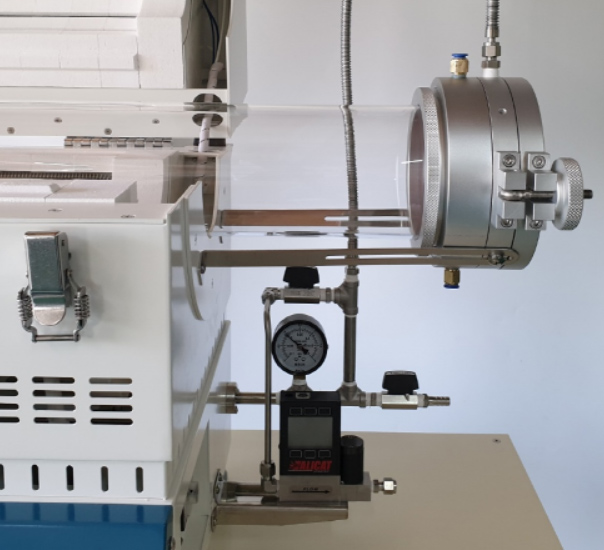

- (Optional) Digital Vacuum Precision Meter by DigiVac

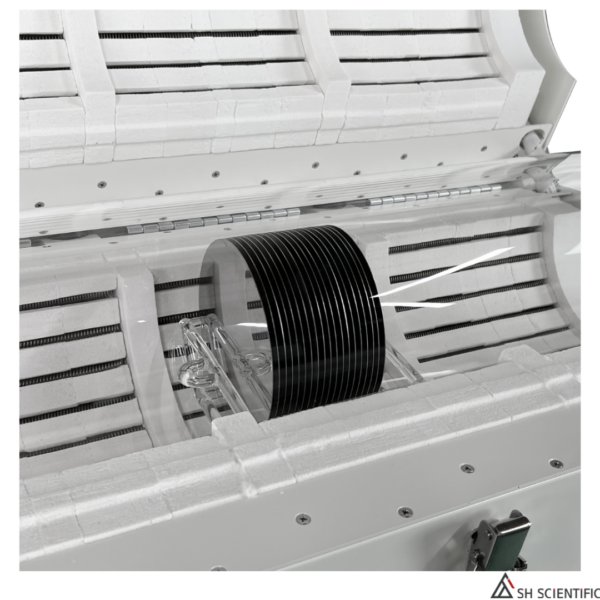

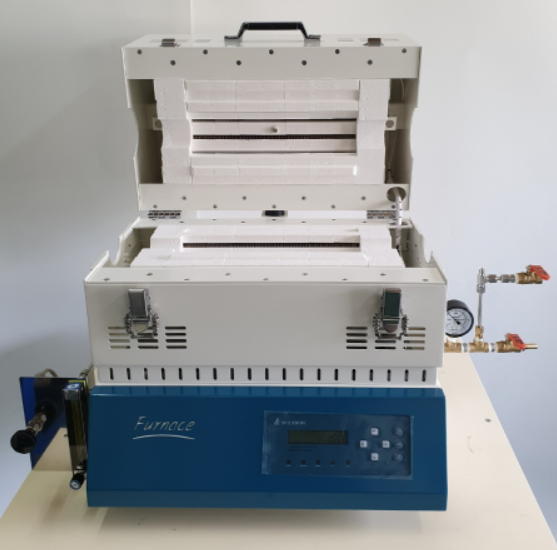

The 250LTG-3-WG model is a large-diameter tube furnace with an inert gas flow management system, designed for versatile and precise thermal processing in non-oxidation environments.

Key Specifications

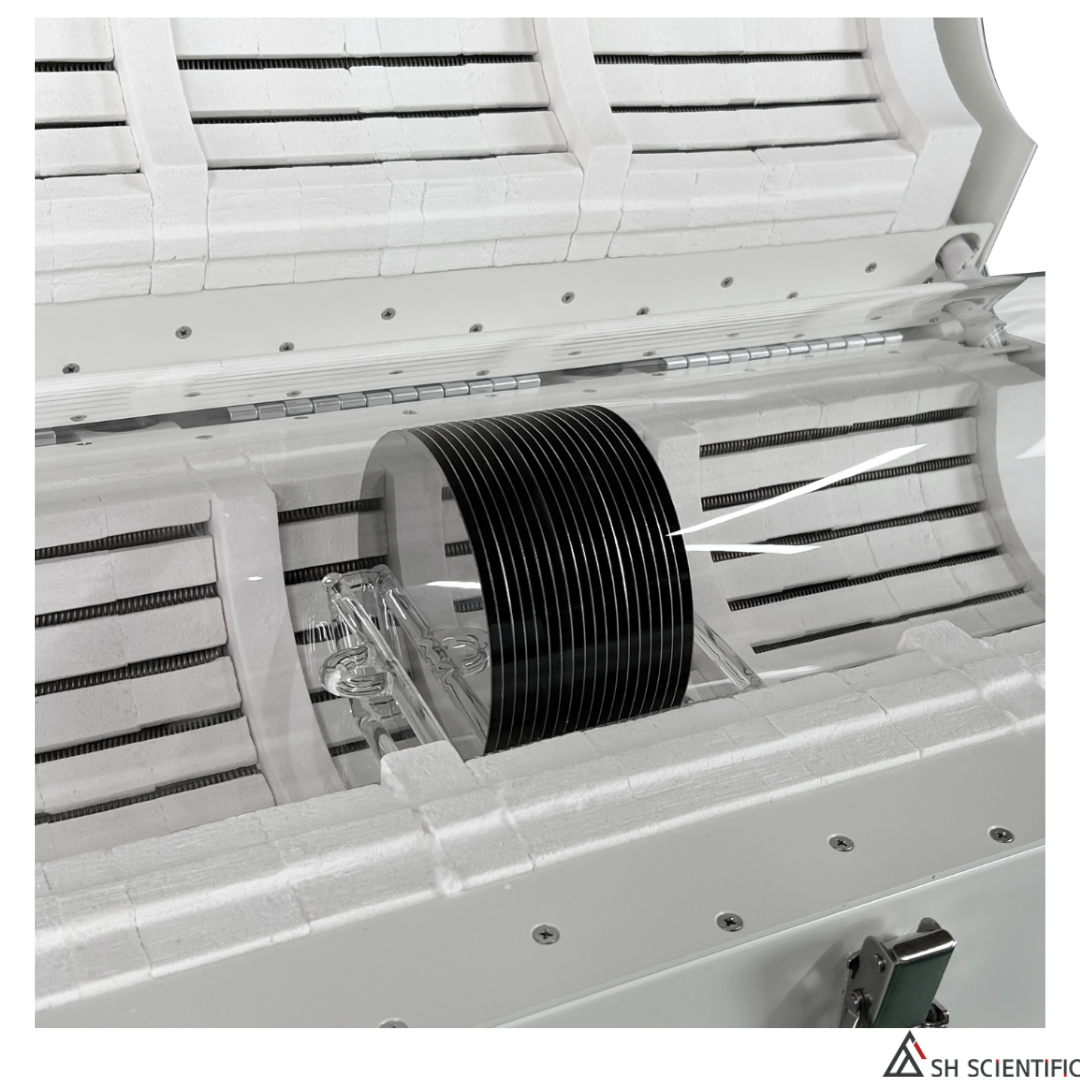

- Large Diameter: 250mm (9.8″ OD, 9.5″ ID) quartz tube, ideal for handling bulky materials, 8″ wafers, and large quantities of powder.

- Temperature Range: Maximum temperature of 1200°C, with an ideal operating range of 1000°C or below for optimal performance.

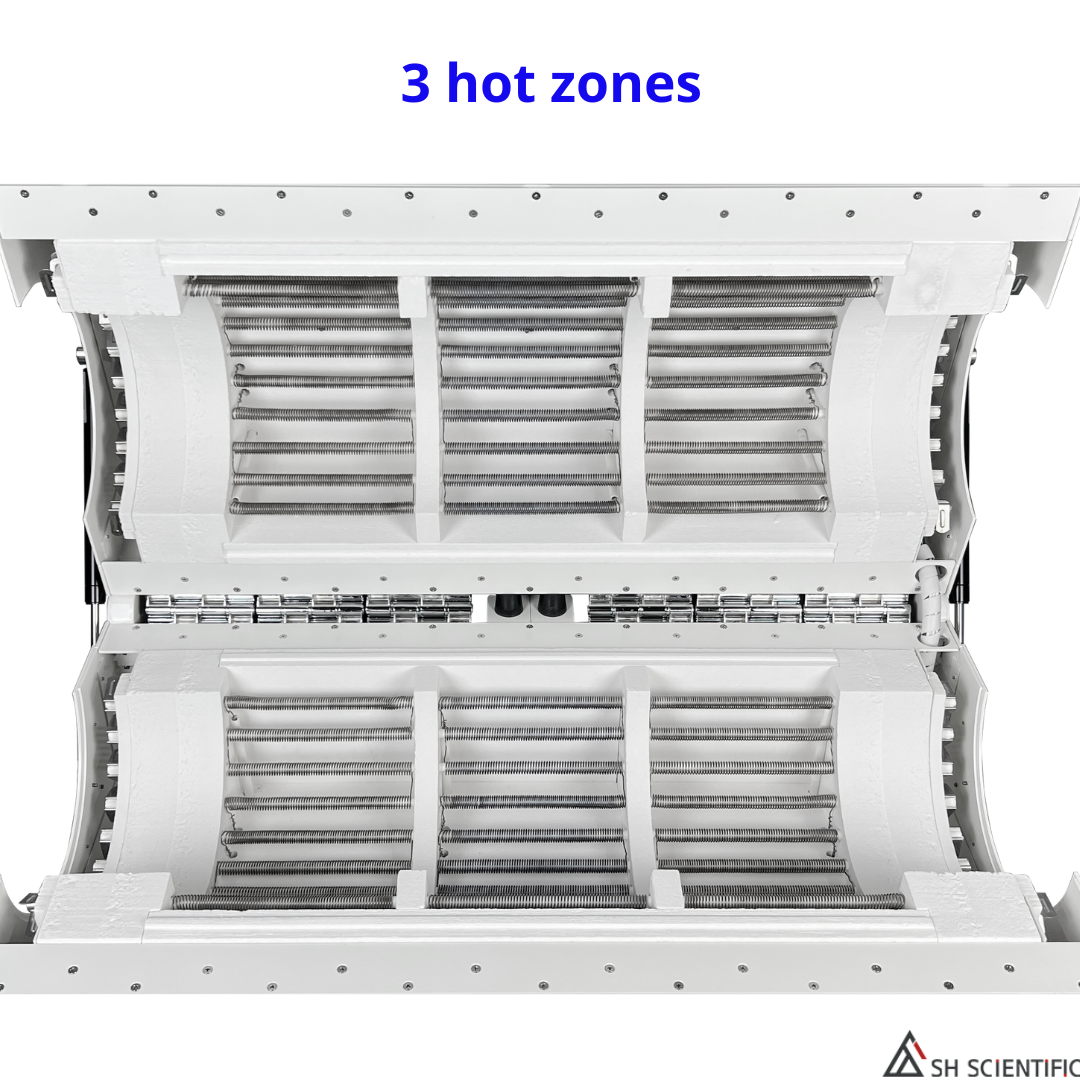

- Heating Zones:

- 3 Independent Hot Zones: Each 200mm (8″) in length, providing a total hot zone length of 600mm (24″).

- Precise Control: 3 independent controllers for custom heating profiles.

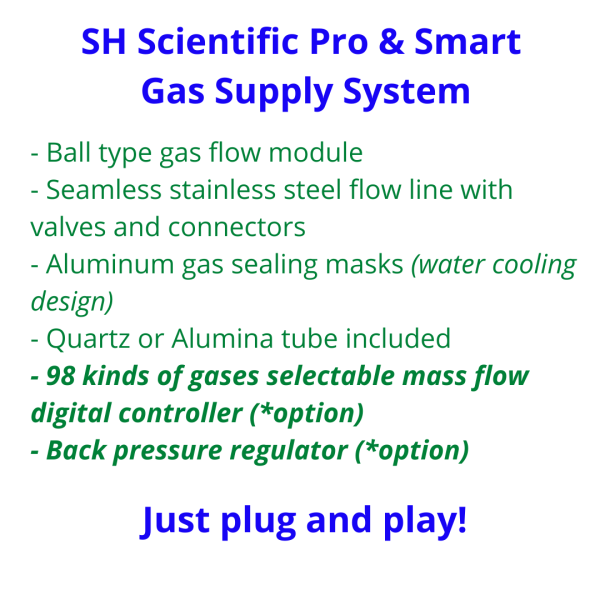

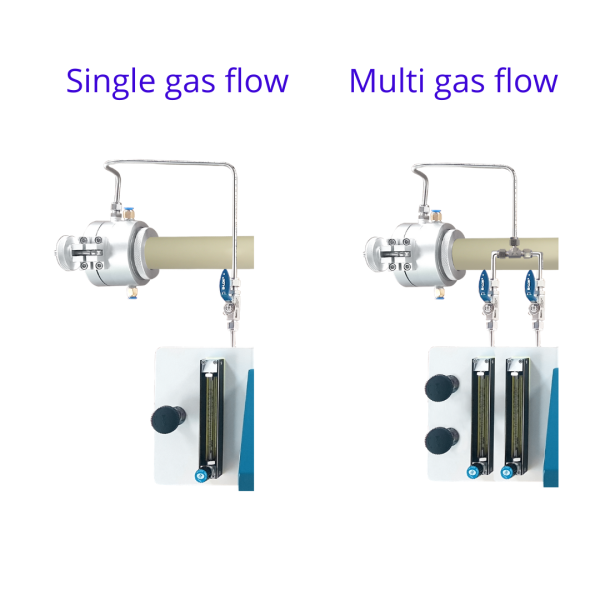

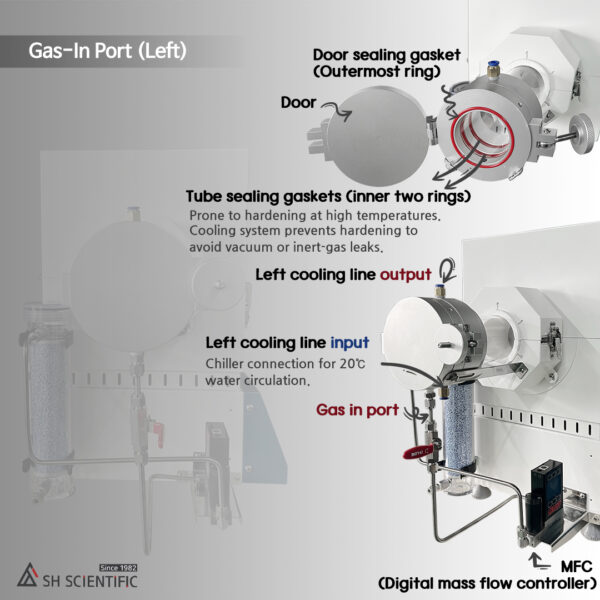

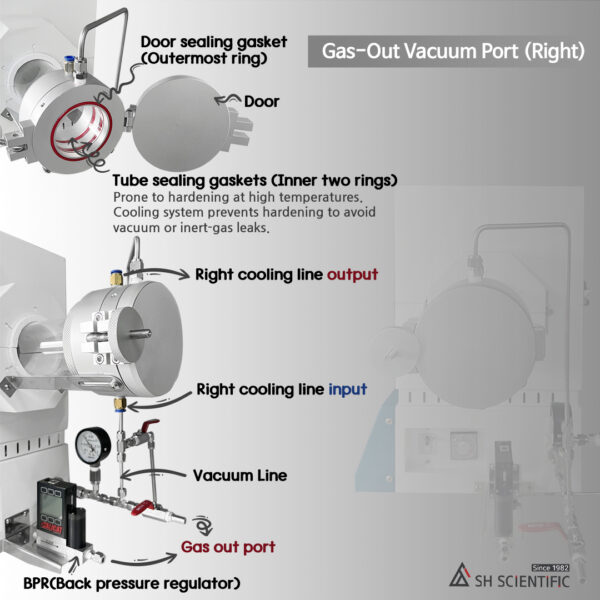

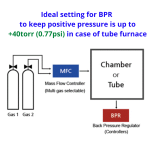

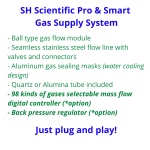

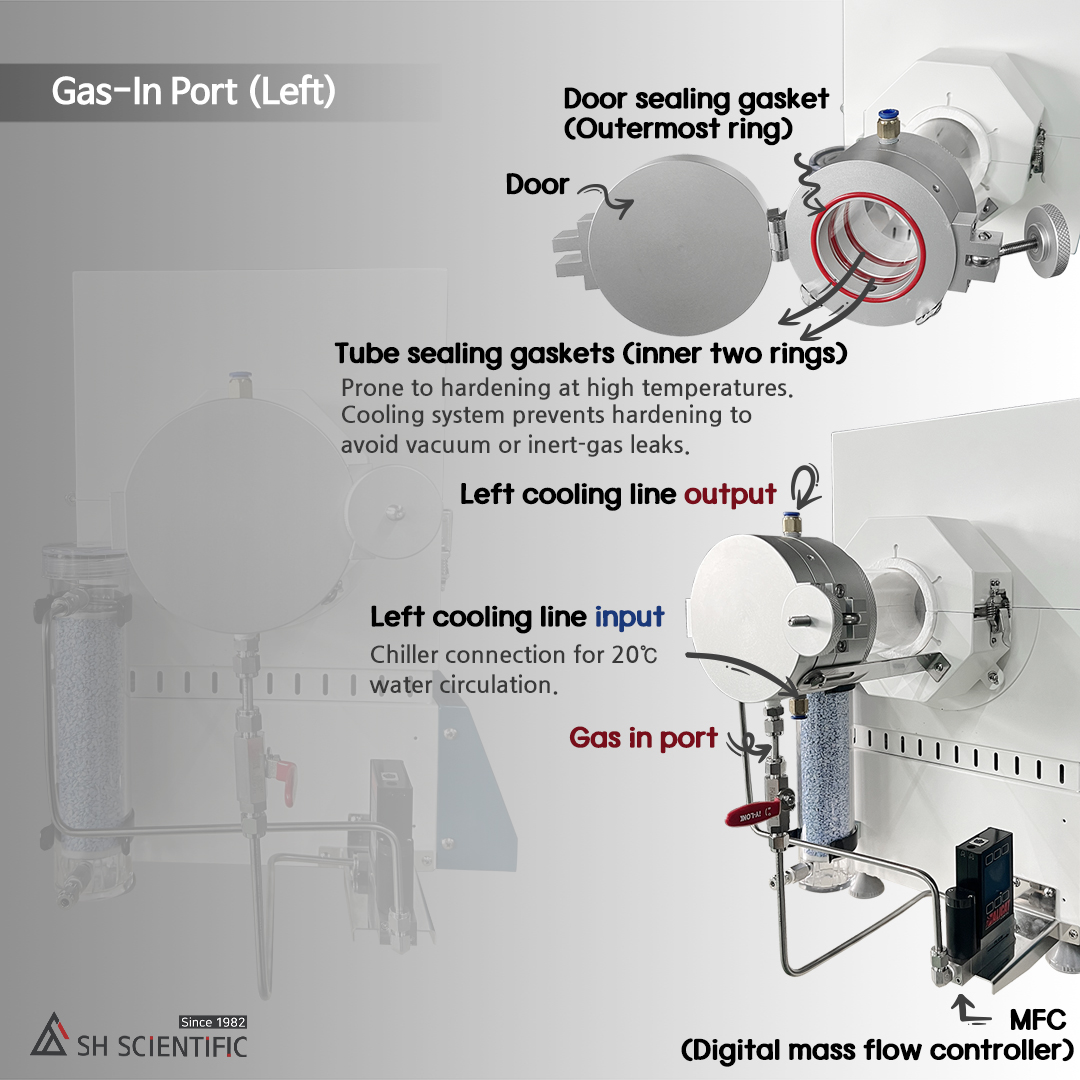

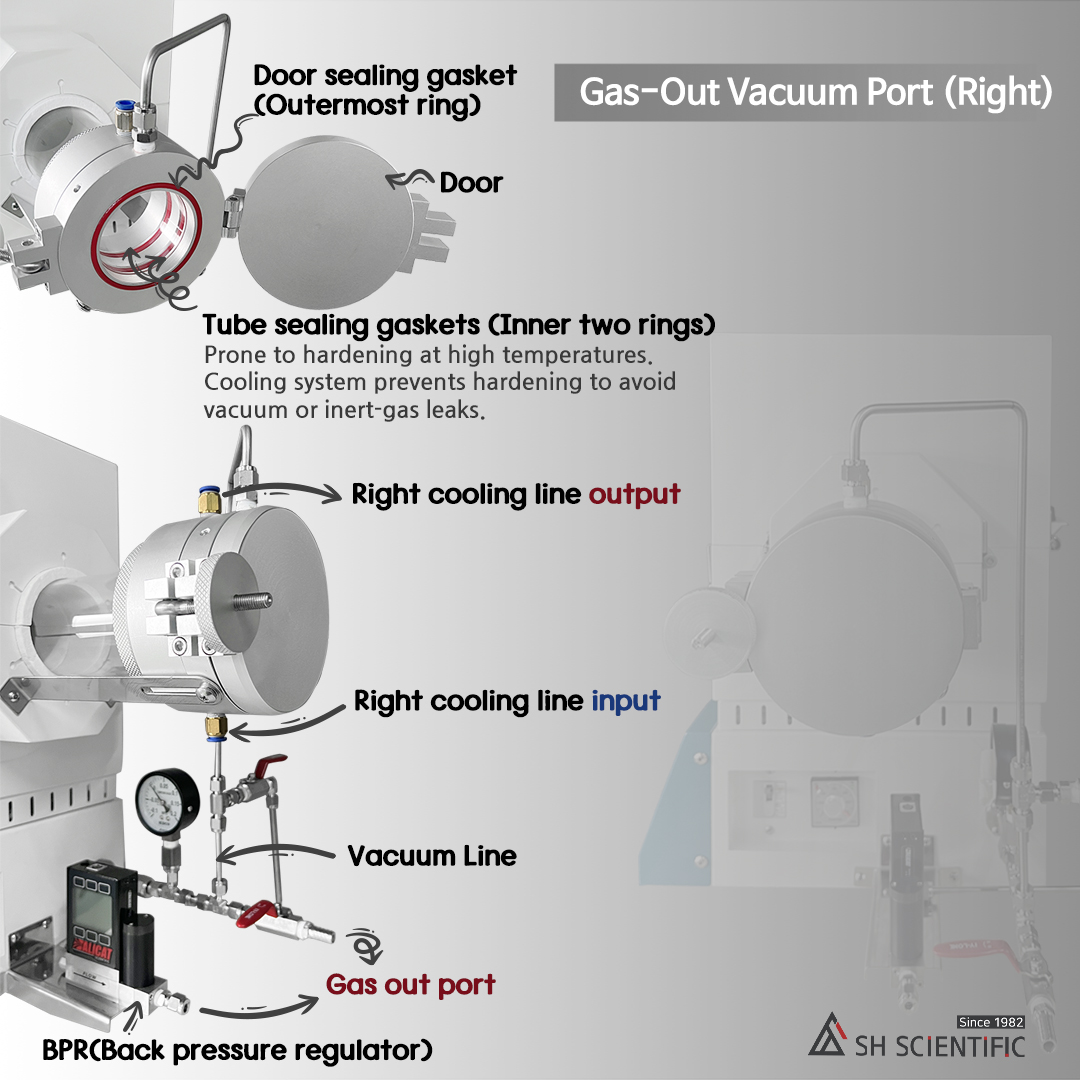

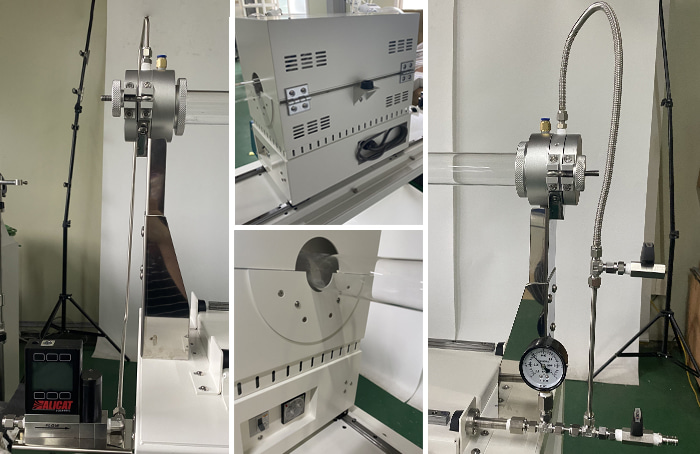

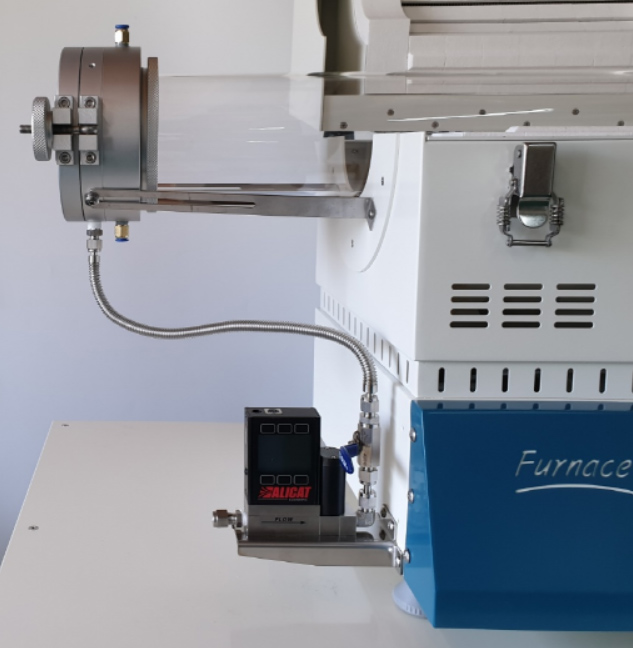

- Advanced Gas Flow System: Includes:

- 1 quartz tube

- 1 ball-type gas flow meter

- 2 aluminum sealing masks

- Stainless steel 316 valves, pipes, and fittings

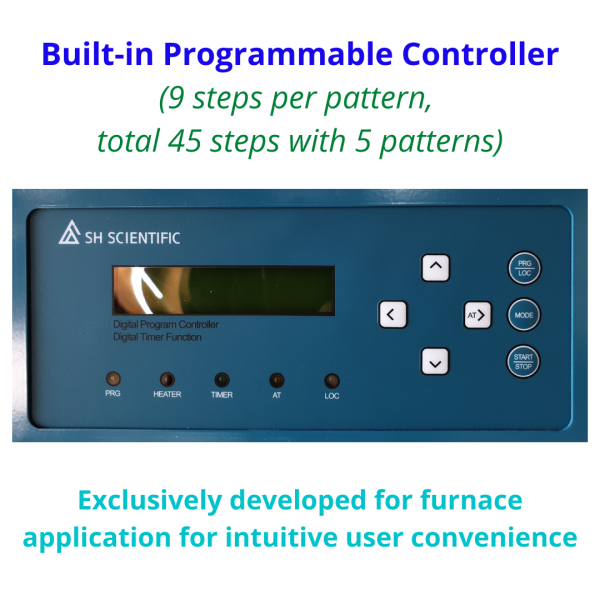

- Programmable Controller: Built-in controller with 5 patterns and 9 segments per pattern, for a total of 45 segments to manage complex thermal cycles.

- Fast Cooling: Efficient cooling with inert gas flow for reduced downtime.

- Convenient Design:

- Advanced end caps for easy sample loading and unloading.

- Easy assembly with plug-and-play functionality.

- Versatile Tube Options: Available in 50/80/100/120mm diameters with 300mm or 600mm hot zone options.

Additional Features

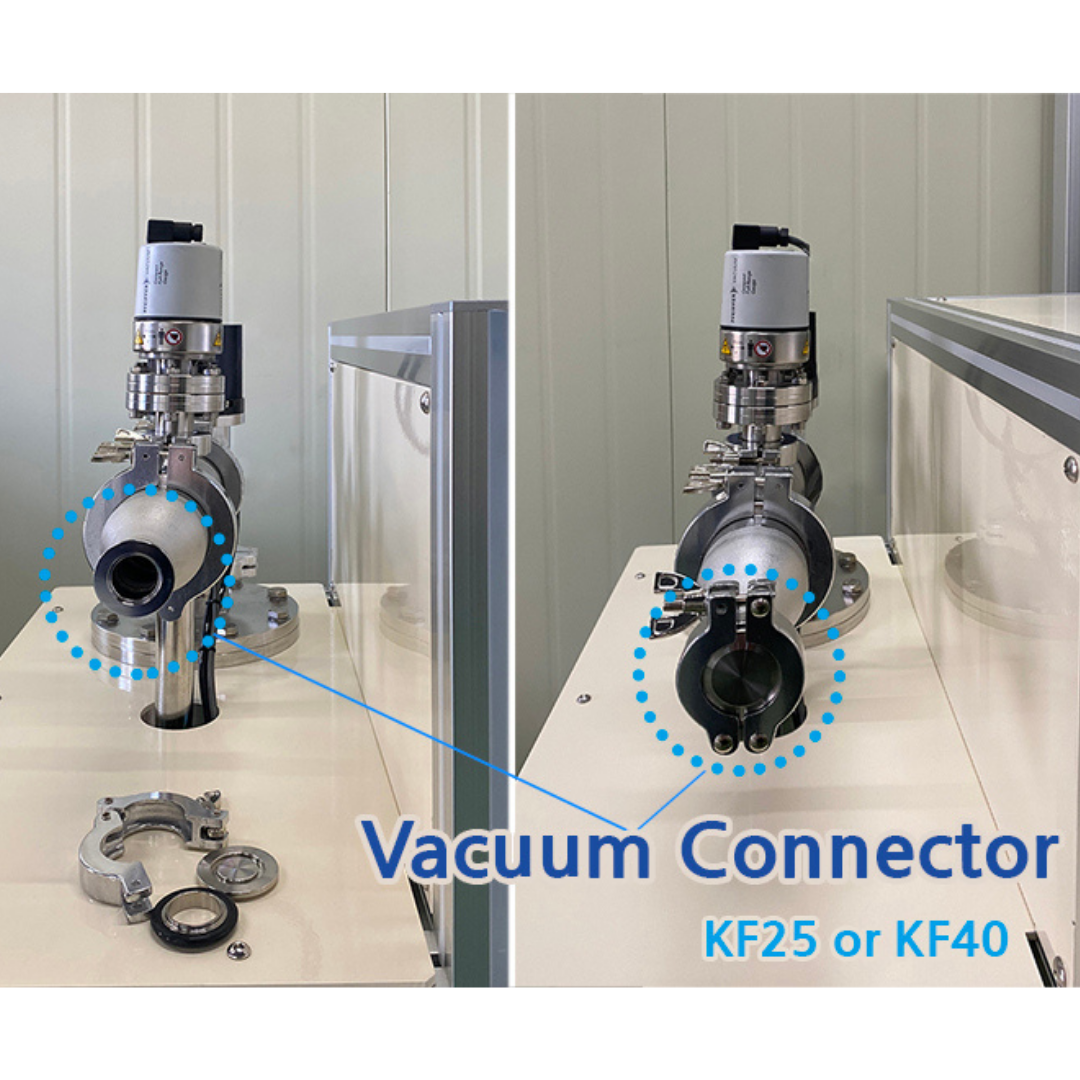

- Turn-Key Compatibility: Can be bundled with a vacuum pump and chiller for a comprehensive turn-key vacuum tube furnace system.

- Safety and Durability:

- Built-in over-temperature protection for safe operation.

- Kanthal heating elements ensure long-lasting performance.

- Double housing design with low surface temperatures (29~30°C at 800°C).

- Precise Temperature Control: SSR operation and a programmable controller offer low noise and temperature precision of ±1°C.

Ideal Applications

- Non-oxidation atmosphere experiments and treatments.

- Advanced research in materials science, including wafers, powders, and bulky sample processing.

The 250LTG-3-WG offers unmatched efficiency, precision, and flexibility for your thermal processing needs. Contact us for customization options or to learn more about our turn-key solutions.

- Description

- Specification

- Customer Photos

- Documents

- FAQ

Description

Built in South Korea, the 250LTG-3-WG model tube furnace showcases SH Scientific’s dedication to efficiency, versatility, and affordability. With a large 250mm diameter and advanced 3-zone heating, this furnace is an exceptional choice for applications requiring precise temperature control and atmospheric customization.

Key Features

- Wide Temperature Range: Operates up to 1200°C with optimal performance at 1000°C, suitable for both standard and advanced heating processes.

- Three Programmable Heating Zones: Features a built-in 45-step controller with heating zones of 3 x 200 mm, enabling precise and complex cyclic treatments.

- Gas Flow Management: As part of the WG series, this model offers advanced control over atmospheric conditions, ideal for sensitive experiments.

- Customizable Tube Sizes: Standard 250mm diameter, with options for other sizes available upon request to meet diverse experimental needs.

- Efficient Thermal Management: Rapid heating and cooling reduce wait times, improving productivity.

- Robust Construction: Double-shell design ensures stability, while digital controllers and customizable options enhance usability.

Applications

SH Scientific’s tube furnaces are widely used in cutting-edge fields such as:

- Secondary and graphene battery research

- Polymer composites processing

- 3D printing material treatment

Available Models

The 250LTG-3-WG is part of a comprehensive range of tube furnaces designed to meet varying research and industrial needs:

- Standalone Tube Furnace (STG/LTG Series): Ideal for basic applications requiring precise heating.

- Tube Furnace with Gas Flow Management (WG Series): Enhances control over atmospheric conditions, making it perfect for sensitive experiments.

- Turn-key Vacuum Tube Furnace System (PK-G Series): A complete solution, including a gas flow management system, vacuum pump, and chiller for advanced research requirements.

Why Choose SH Scientific?

- Customization: Tailored configurations to suit specific requirements.

- Economical Operation: Cost-effective for small-sample processing and specialized atmospheres.

- Comprehensive Solutions: Turn-key systems with advanced accessories for seamless setup and use.

Customization and Support

Our expertise in gas flow management systems ensures optimal performance for demanding applications. Need something unique? Contact us to discuss fully customized solutions designed to meet your needs.

Elevate your research and industrial processes with the 250LTG-3-WG model tube furnace and other models in SH Scientific’s innovative furnace lineup.

|

Model |

SH-FU-250LTG-3-WG |

|

Max temperature |

1200℃ |

|

Continuous running temperature |

1000℃ |

|

Tube diameter |

250mm (9.8″ OD, 9.5″ ID) |

|

Controller |

45 Segments Programmable Controller FC-1000 |

|

Sensor |

K type |

|

Heater |

4.6kW x 3 zones, total 13.8kW |

|

Hot zone |

200mm x 3 zones, total 600mm |

|

Heating element |

Kanthal A-1 with ceramic molding |

|

Insulation |

Ceramic |

|

External size |

850 L x 600 D x 880 H mm

33.4 L x 23.6 D x 34.7 H inch |

|

Weight |

|

|

Power supply |

220V, 50/60Hz, 3P, 35A 380V, 50/60Hz, 3P, 21A |

Content missing