Large Scale Vacuum Drying Oven Turnkey System

$0

Introducing SH Scientific’s Custom Developed Vacuum Drying Oven.

Operating within a temperature range of 250 to 350°C, the national forest research lab required a vacuum drying oven featuring a spacious and deep chamber to facilitate their research in biomass torrefaction, also known as mild pyrolysis.

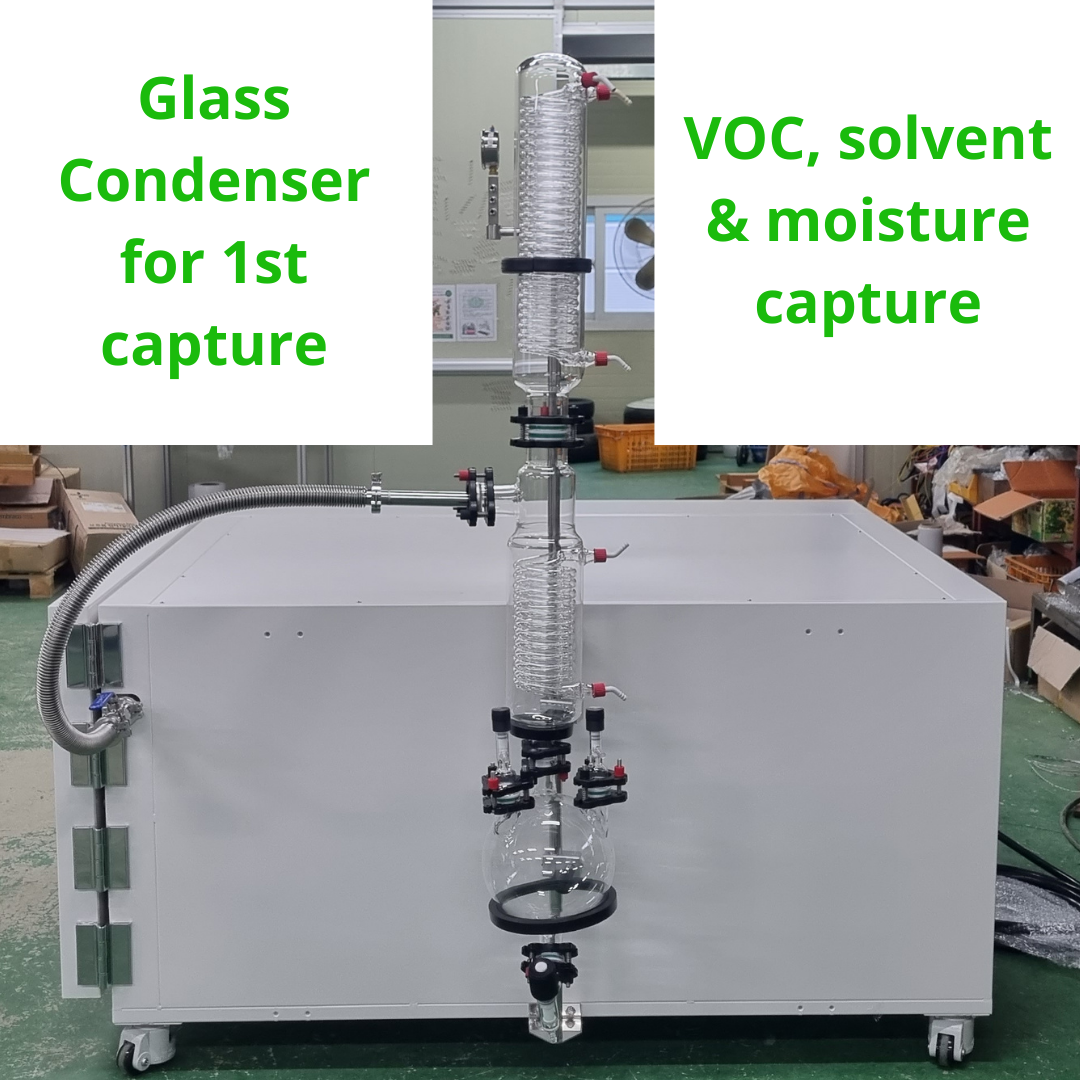

Crucially, the process of drying biomass releases significant quantities of water, bio-oil, and various organic volatiles, including organic acids, alcohols, and phenolic compounds, all in the liquid phase. Therefore, it was imperative to integrate a multi-stage capture apparatus into the system, positioned before the vacuum pump, to efficiently condense and remove these substances.

Key Features:

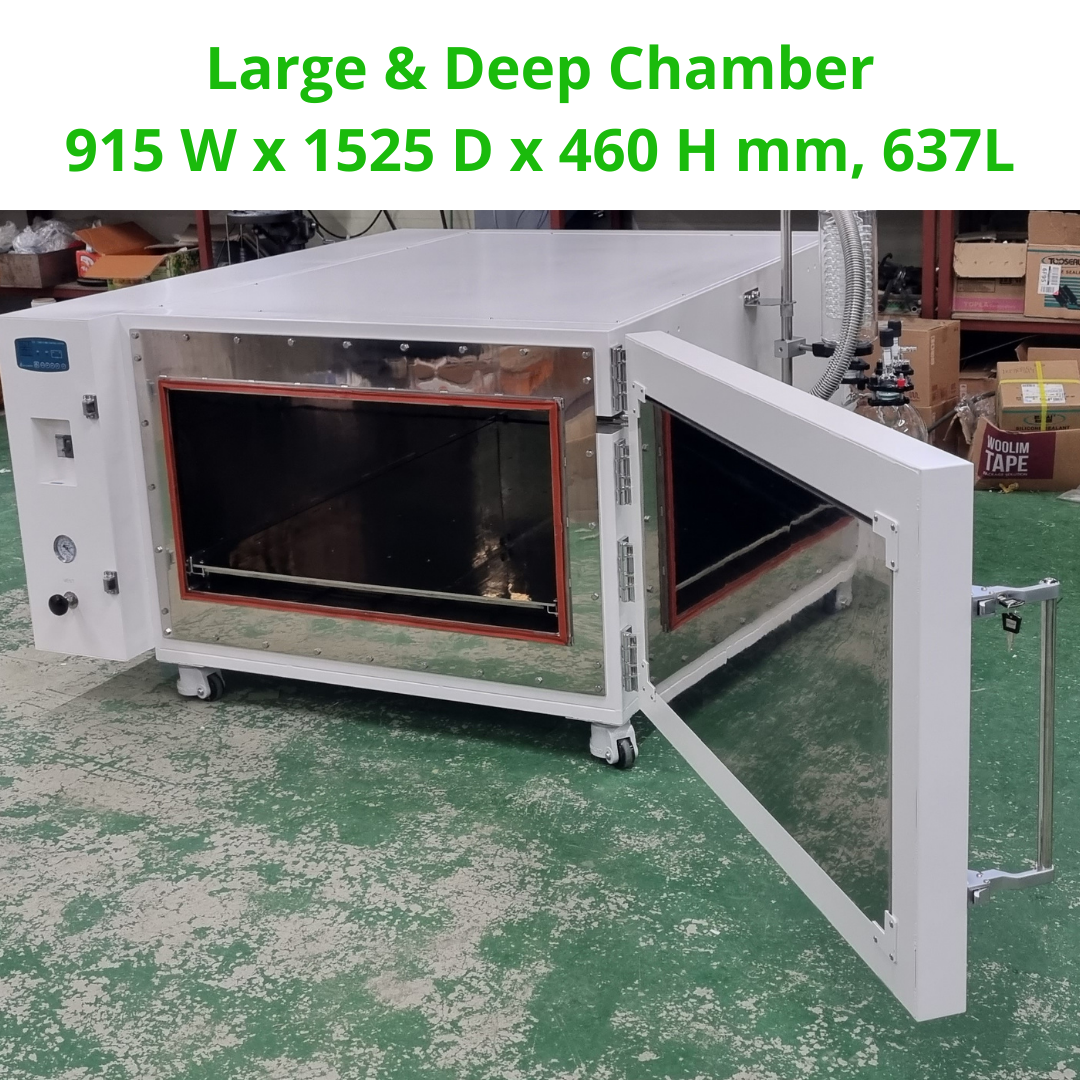

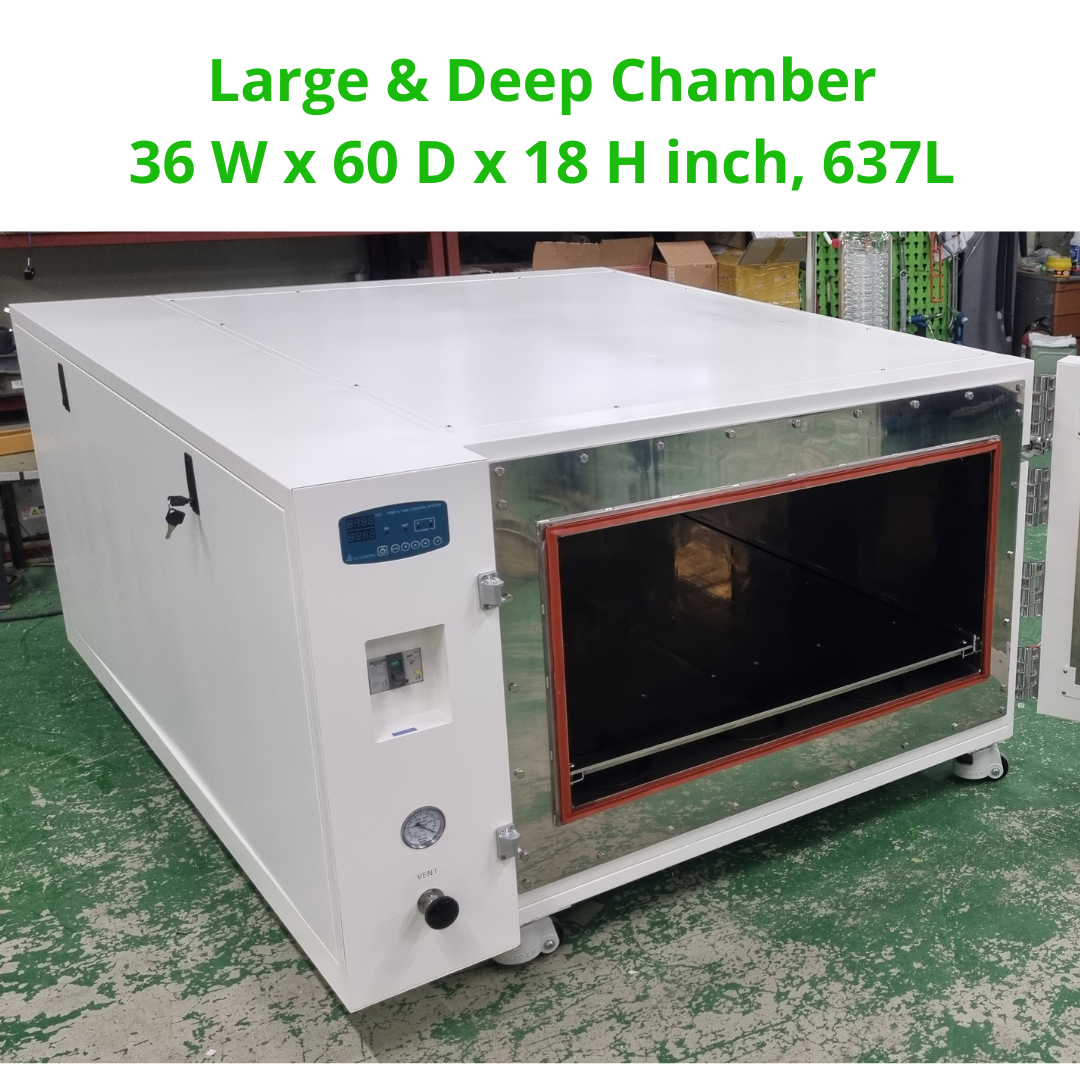

- Large and Deep Chamber: With a capacity of 637 liters (36 W x 60 D x 18 H inches), our oven accommodates substantial quantities of biomass, facilitating large-scale experiments and speeding up the research process.

- Enhanced Heating System: The oven features a directly heated shelf, ensuring prompt and uniform heat distribution across all materials, a critical factor for achieving consistent torrefaction results.

- Heavy Load Capability: Designed to withstand heavy loads, the shelf can support up to 100 lbs of material weight, allowing for versatile research applications.

- Advanced Capture Apparatus: Recognizing the release of water, bio-oil, and other organic volatiles during the drying process, we incorporated a multi-stage capture apparatus. This includes a glass condenser and a -30°C chiller for the first stage of VOC and moisture capture, capable of condensing 1.5 to 3 liters per hour, followed by a -75°C industrial-scale cold trap bath with four 3.5-liter glass traps for the second stage, ensuring a clean and safe operating environment.

- Power Efficiency: Powered by 220V 3P, the system is engineered for energy efficiency without compromising on performance.

- Description

- Specification

- FAQ

Description

Description

SH Scientific’s Tailored Solution for a Prestigious National Forest Research Lab

In the quest for advancing sustainable energy sources, a leading national forest research lab sought a highly specialized piece of equipment: a vacuum drying oven capable of conducting biomass torrefaction (mild pyrolysis) research. Understanding the intricacies of this request, SH Scientific embarked on developing a one-stop turnkey system that not only meets but exceeds the lab’s expectations, marking a significant milestone in research and development in the field of renewable energy.

Our client approached us with a need for a vacuum drying oven capable of operating at temperatures ranging from 250°C to 350°C. The project’s core requirement was a large and deep chamber oven to support their research into biomass torrefaction, a mild form of pyrolysis aimed at enhancing the properties of biomass as a renewable energy source. This process, crucial for advancing renewable energy technologies, demands precision equipment to handle the complex dynamics of biomass processing.

The core challenge was to design an oven with a large and deep chamber that could ensure uniform heat distribution across the shelf, despite its spacious interior. This was crucial for the accurate and efficient processing of biomass materials. Additionally, the oven needed to be robust enough to support up to 100lbs of material weight, accommodating substantial quantities of biomass for torrefaction.

Recognizing the complexity of the process, which involves the release of a considerable amount of volatile organic compounds (VOCs) and moisture, it was imperative to incorporate a multi-stage capture system. This system is essential for efficiently condensing and capturing these by-products, ensuring a clean and safe research environment.

To address these requirements, SH Scientific delivered a holistic turnkey solution comprising a large-scale vacuum drying oven with a directly heated shelf to ensure even heat distribution, a glass condenser paired with a -30°C chiller for the initial capture of VOCs and moisture, followed by a -75°C industrial-scale cold trap bath equipped for the secondary capture phase, and a vacuum pump. This comprehensive setup exemplifies SH Scientific’s commitment to supporting cutting-edge research through the provision of customized, precision-engineered laboratory solutions.

Specification

| Category | Description |

| Model | SH-FU-637NS-PK |

| Max Temperature | 450℃ |

| Continuous Running Temperature | 350°C |

| Chamber size | 915 W x 1525 D x 460 H mm, 637L

(36 W x 60 D x 18 H inch) |

| Controller | 30 steps programmable controller |

| Heating method | Shelf direct heating |

| Heater | 12.0kW |

| External Dimension & Weight | 1700 W x 2100 D x 1080 H mm, 1030kg

(67 W x 83 D x 43 H inch, 2290lbs)

|

| Internal Material | Stainless steel |

| External Material | Steel plate with powder coated |

| Custom Feature |

|

| Power | 220V 3P 33A * vacuum oven

220V 1P * chiller, cold trap & pump |

FAQ

Content missing