- "Power Voltage Option" is a required field.

- "Add Vacuum Pump" is a required field.

Our Clients

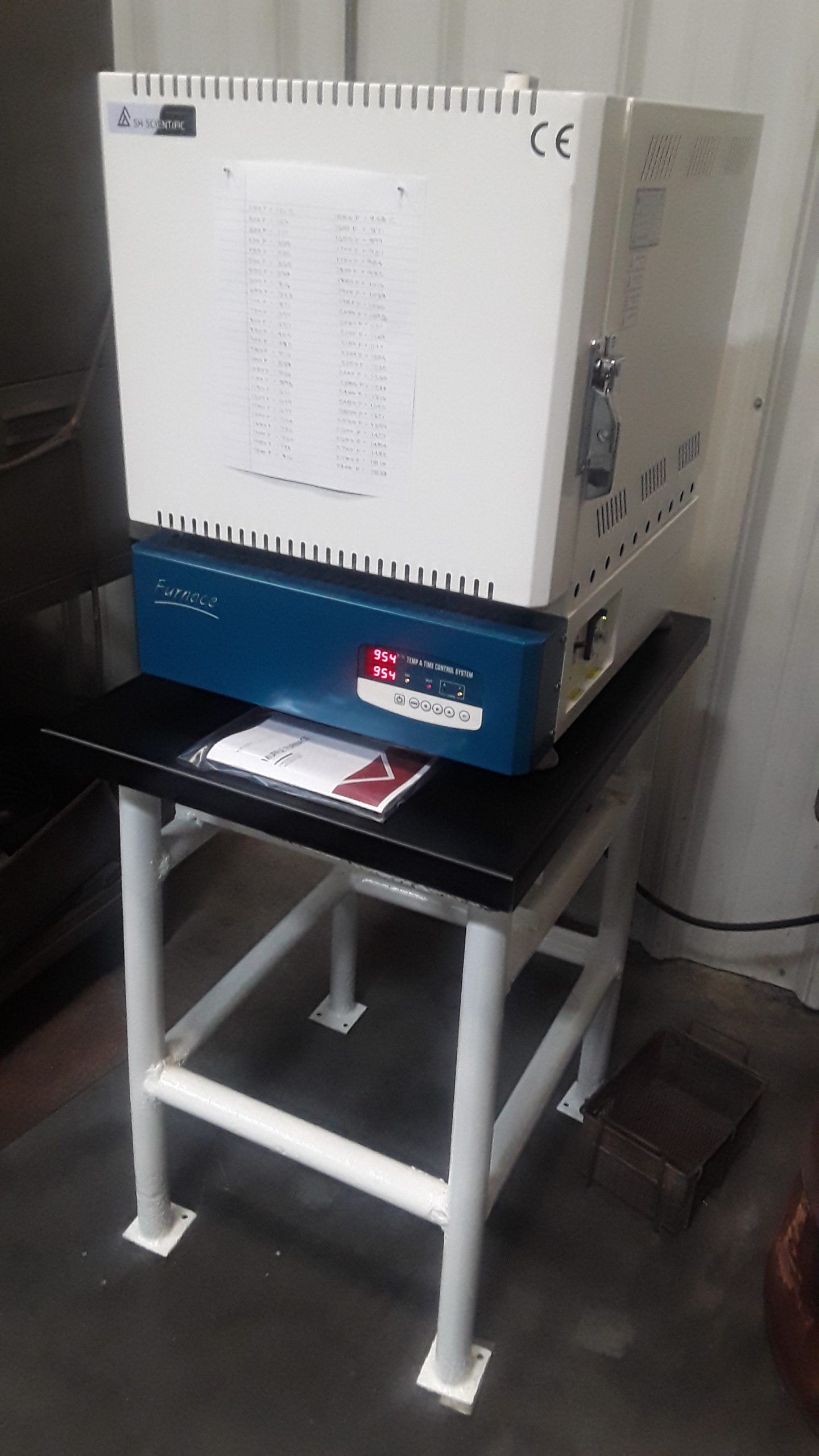

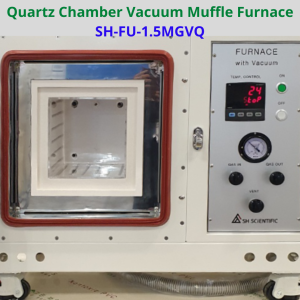

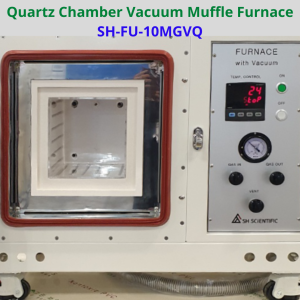

31MGVQ – 1,200°C – SH Quartz Chamber Vacuum Muffle Furnace

$24,330

- Harmful gas & fume removal protects laboratory air quality

- Three-stage filtration system. Pre-filter, HEPA filter and VOC filter

- Adjustable airflow. 10 levels of air intake and exhaust volume adjustment

- Ductless operation

- (Optional) Testo 300 Combustion Gas Analyzer for Monitoring Oxygen-free atmosphere inside the chamber or tube and measure combustion gas and synthetic gas components – Contact us for available options

- (Optional) Laboratory Gas-Drying Unit by Drierite™ with Connector

- (Optional) Quartz Shelf Designed to Maximize Available Space in the Chamber

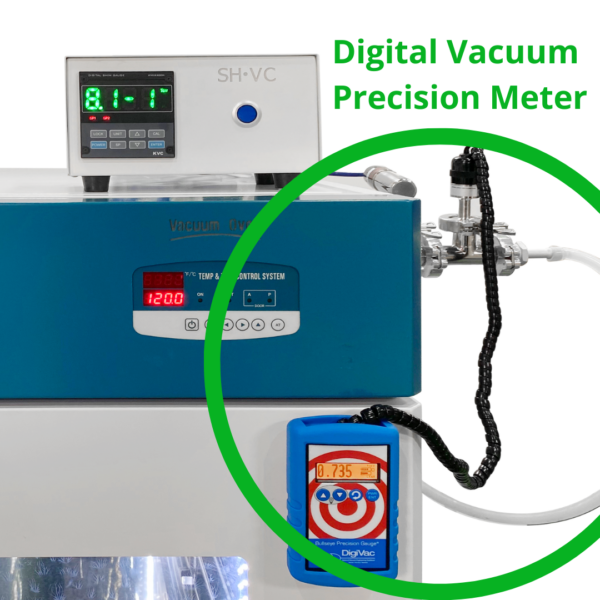

- (Optional) Digital Vacuum Precision Meter by DigiVac

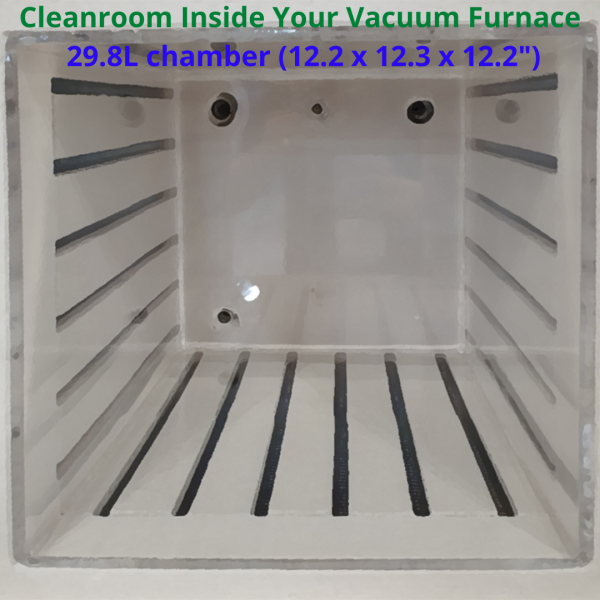

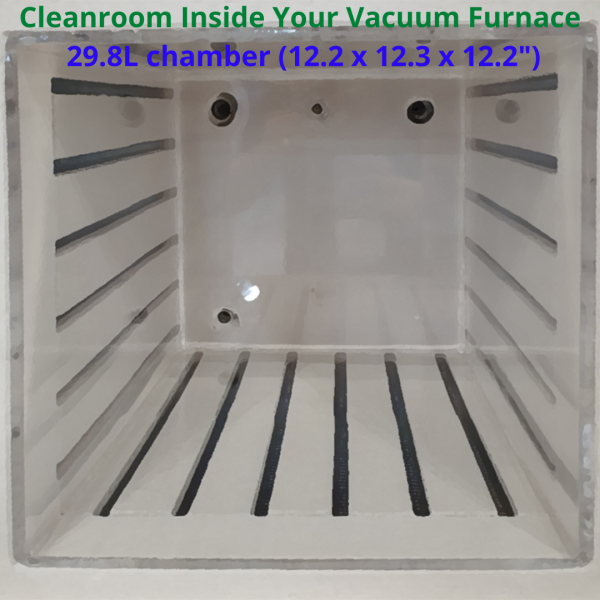

- 29.8L (12.2 x 12.3 x 12.2″) Quartz chamber vacuum muffle furnace.

- Non-contaminating CLEANROOM condition.

- Maximize SAMPLE PURITY and HEATING ELEMENT LONGEVITY.

- Complete atmospheric control for non-oxidation environment.

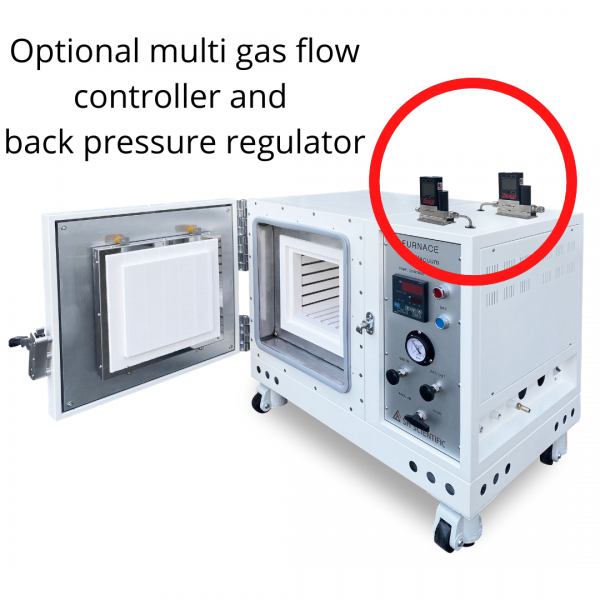

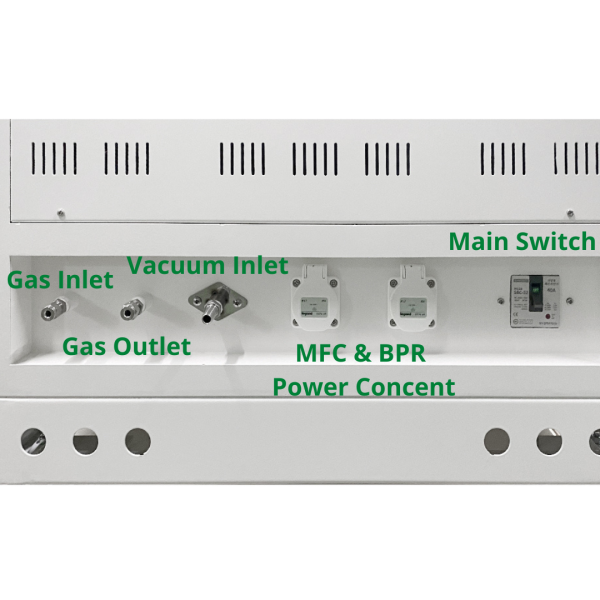

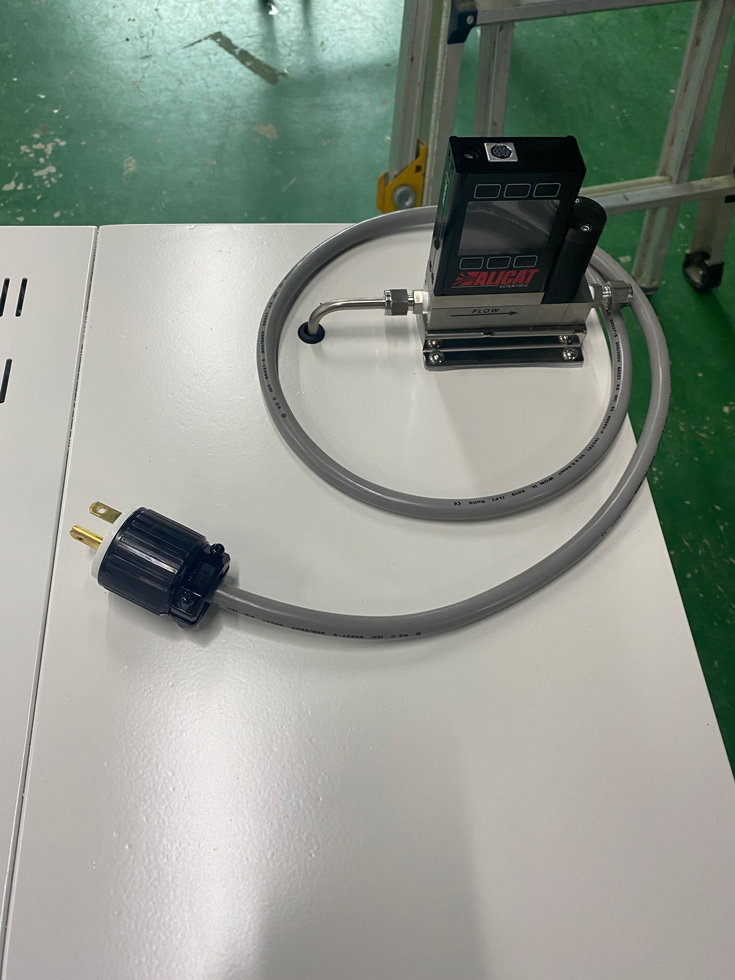

- An optional mass flow controller for precise, responsive and stable gas management across 98 inert gas presets, supported by a back pressure regulator to maintain positive pressure inside the chamber

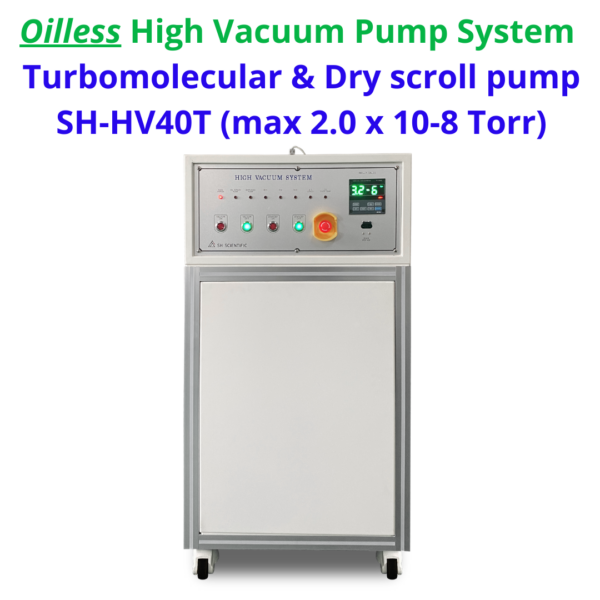

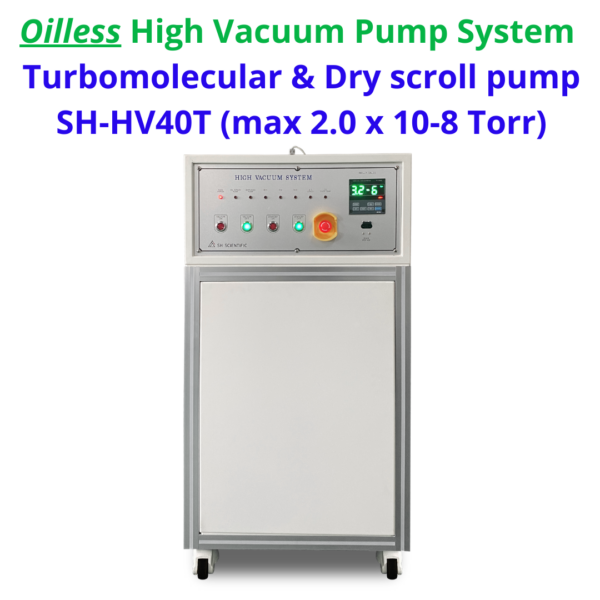

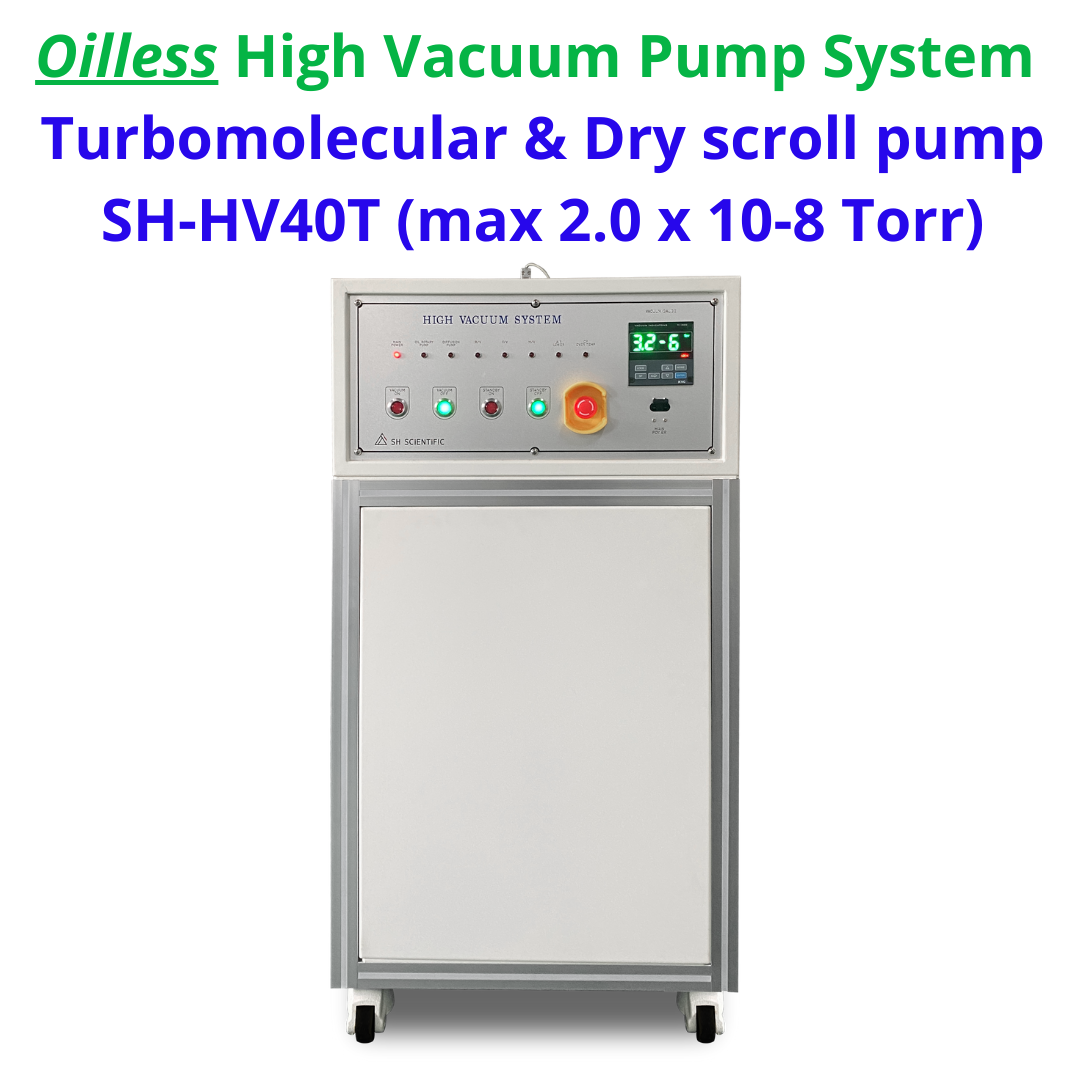

- An available vacuum pump with flow speed of 596L/min (21cfm)

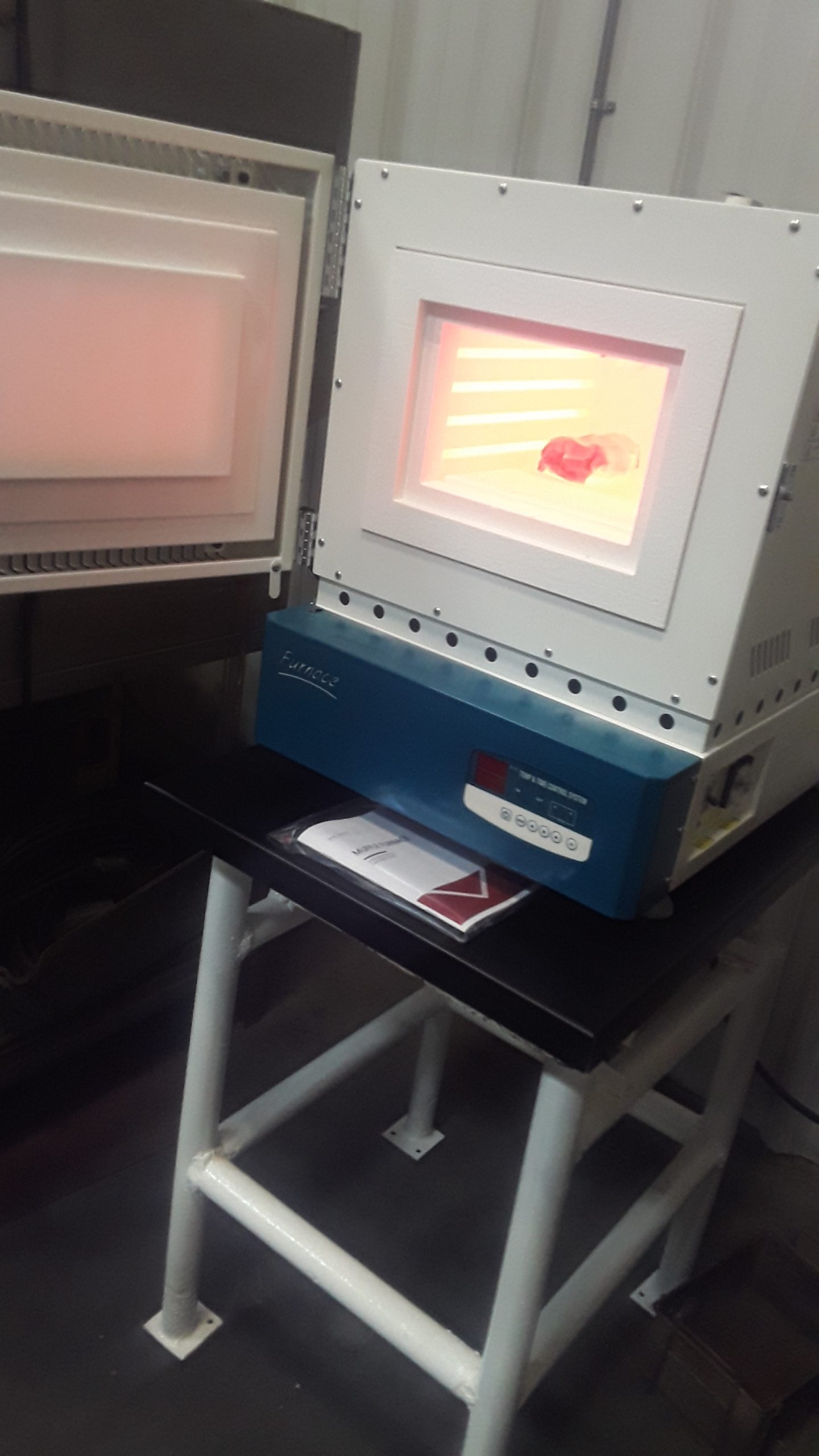

- Creating your multiple atmospheric environment (burning in air, purging air and pulling vacuum, flowing inert gas and sintering)

- No limitation on materials sizes compared to the ones with tube furnace

- Support hardening, annealing, tempering, brazing and sintering with or without vacuum

- Vacuum heat treating and vacuum brazing

- Recommended ideal running temperature is below 1000°C

- Description

- Specification

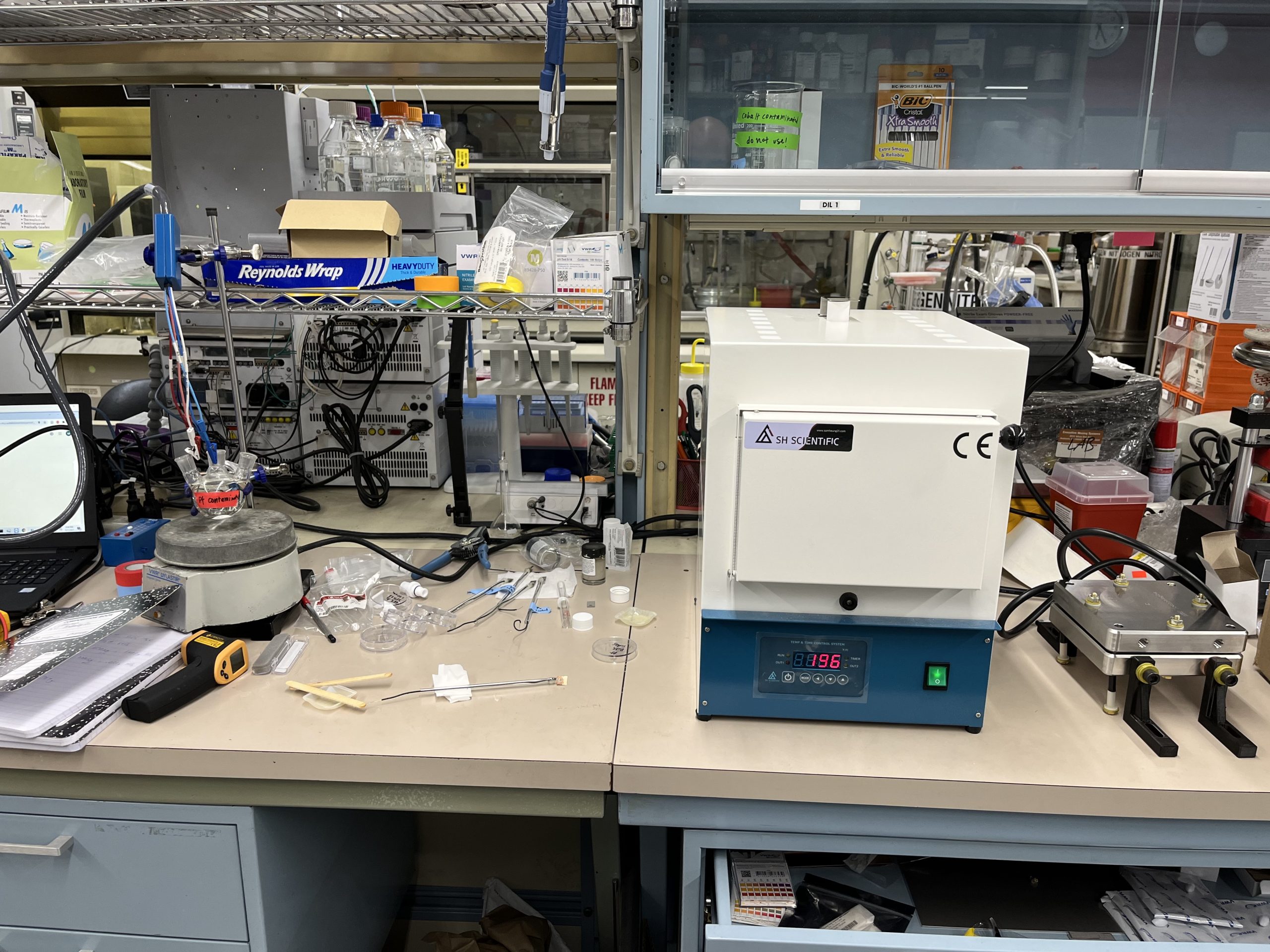

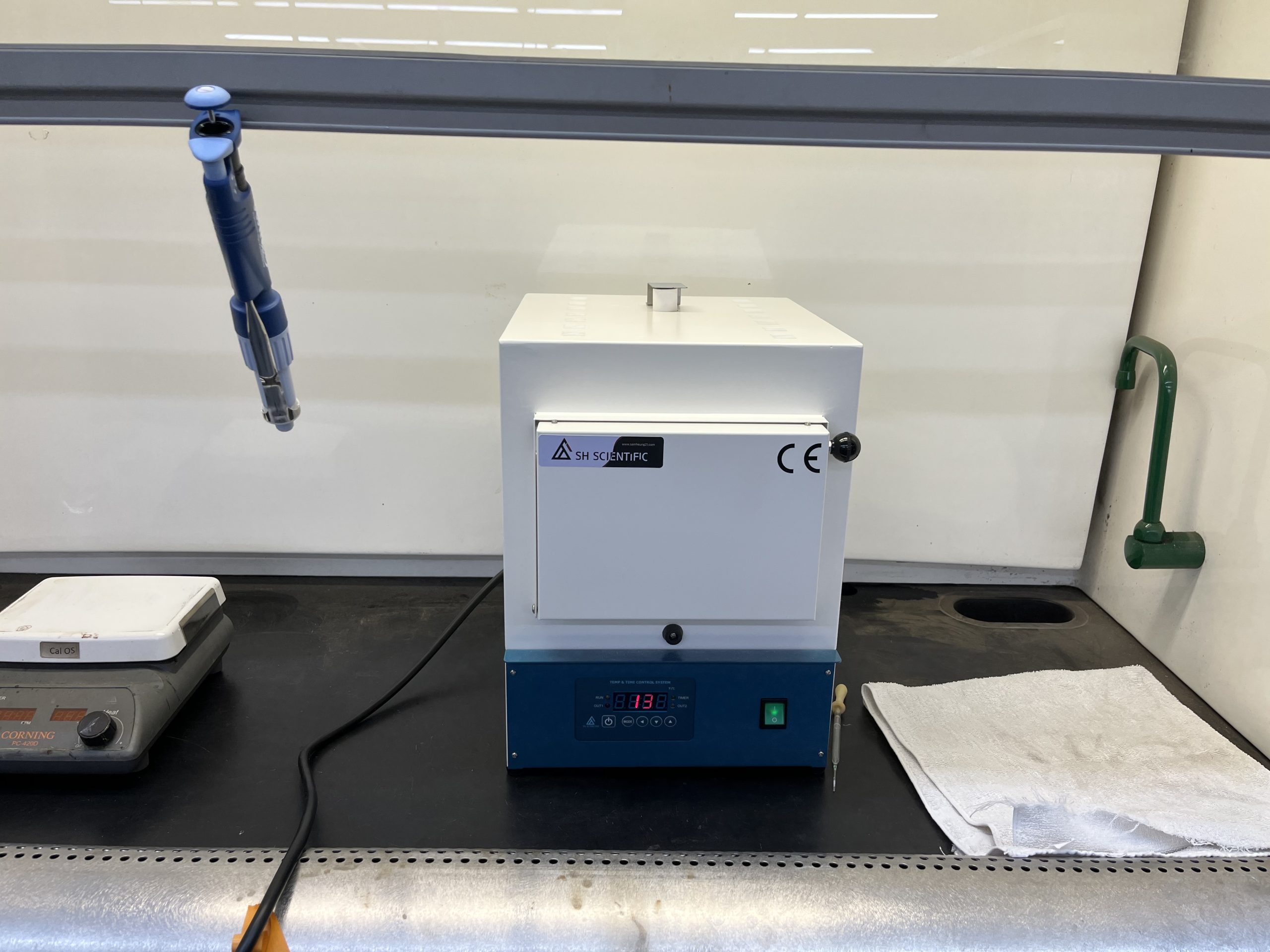

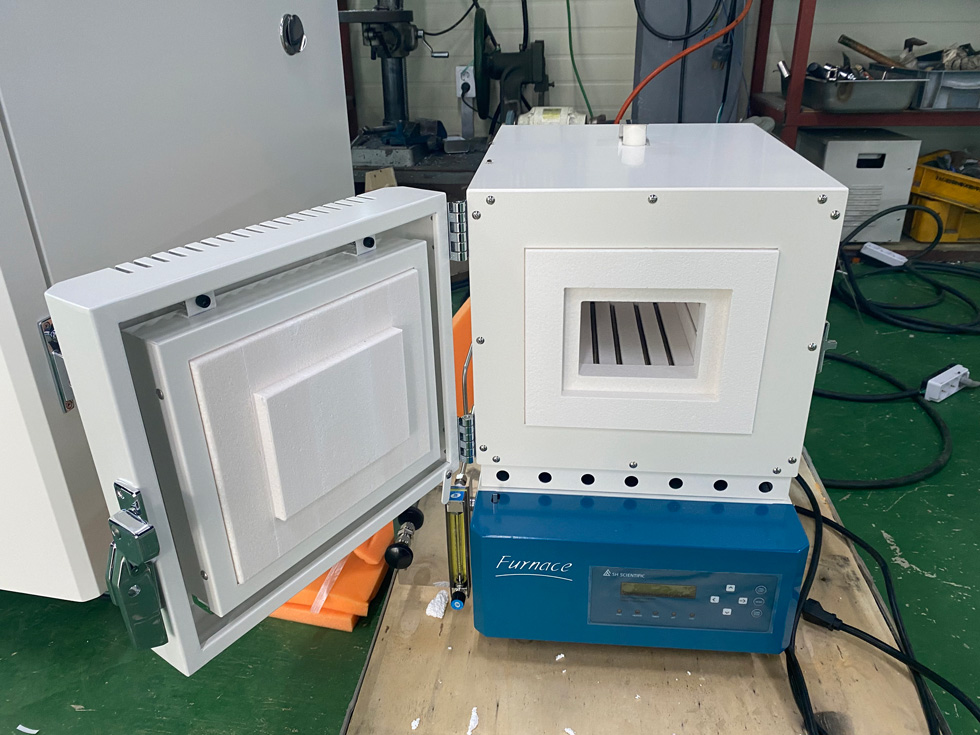

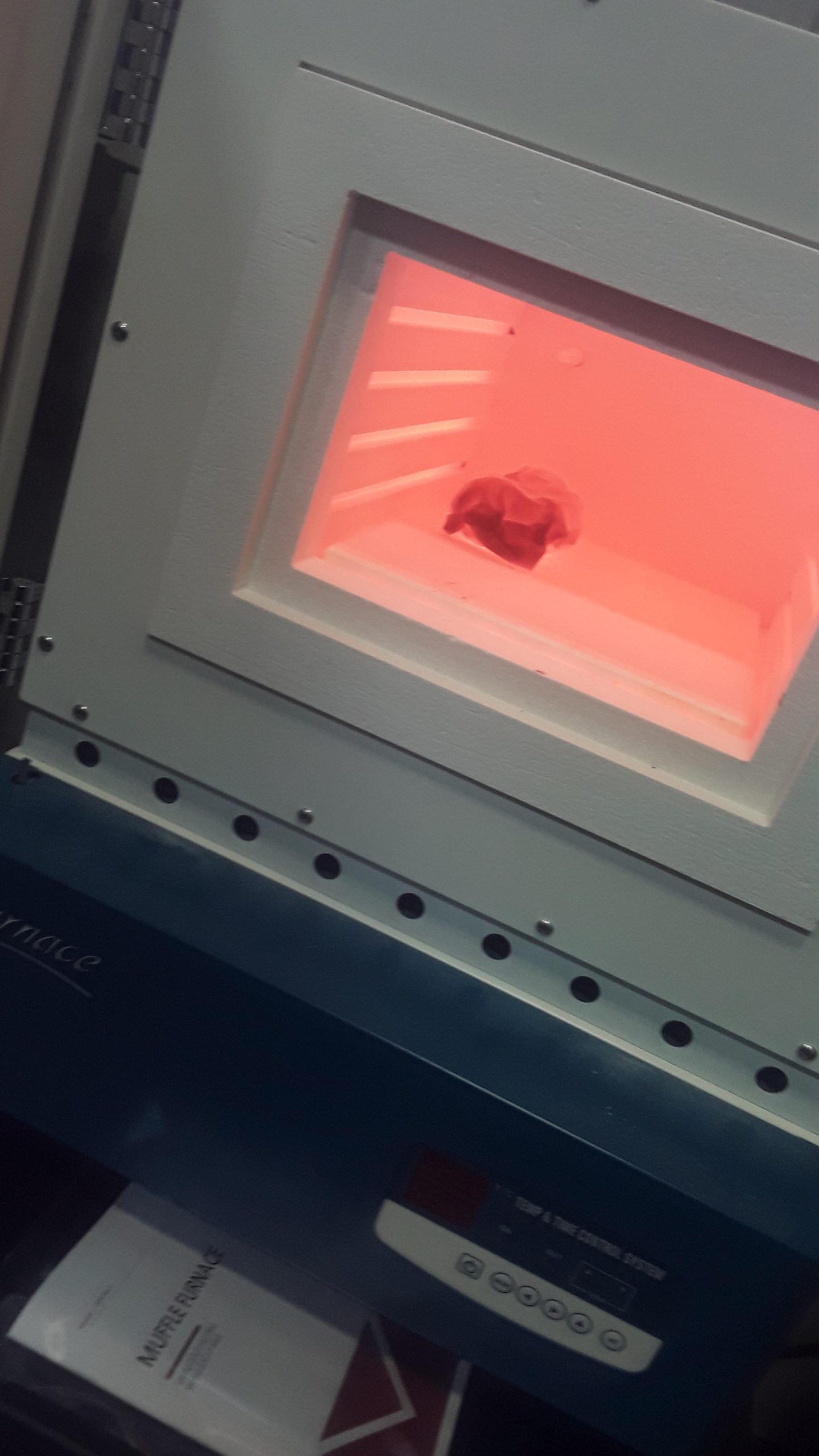

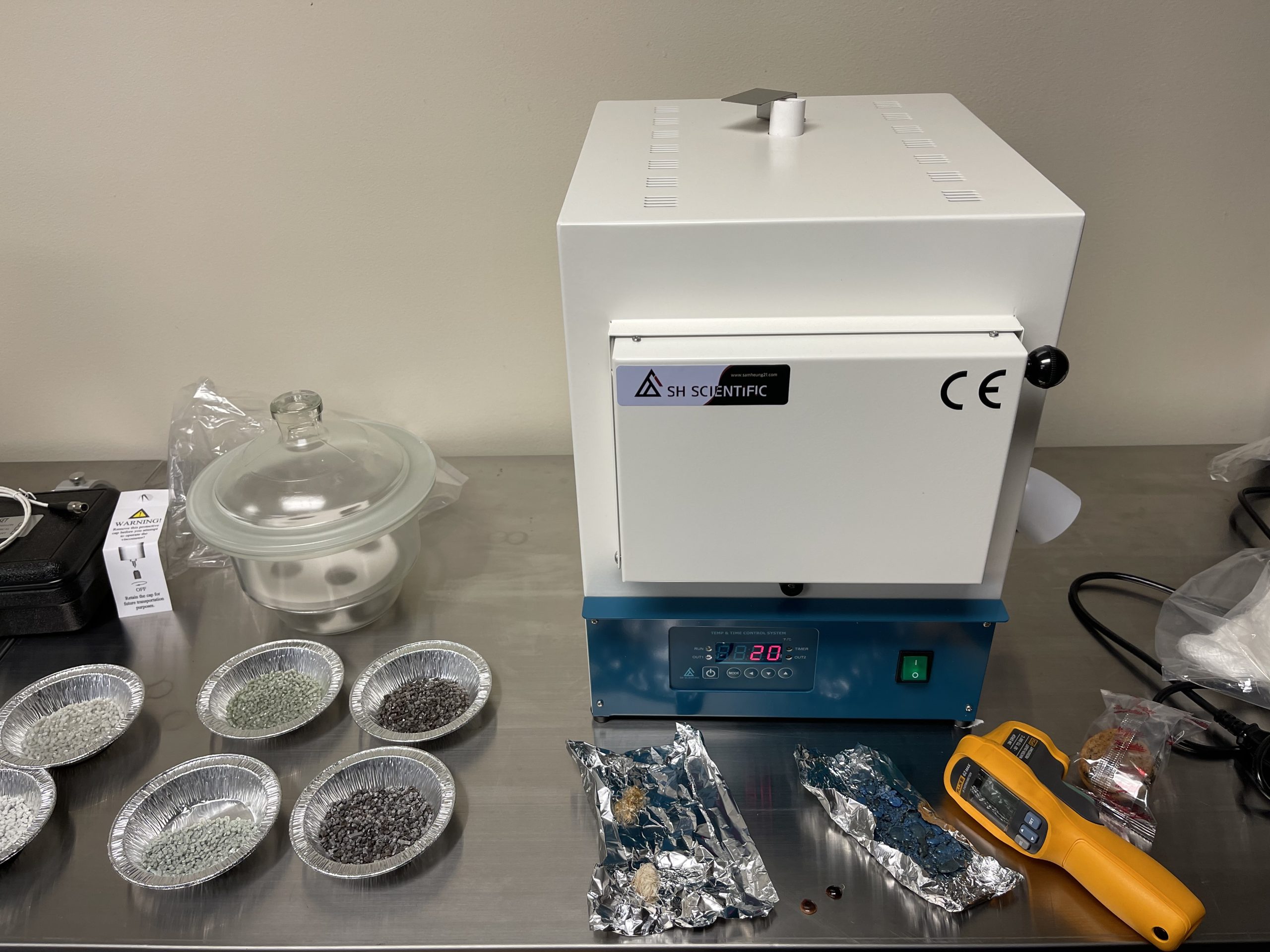

- Customer Photos

- Documents

- Reviews (0)

- FAQ

Description

Description

CLEANROOM INSIDE YOUR VACUUM MUFFLE FURNACE!

New MGVQ Series!

Our MGVQ line of QUARTZ CHAMBER vacuum muffle furnaces provide a cleanroom right inside your furnace’s chamber.

This series brings comprehensive programmability and complete gas flow control-ideal for calcination, sintering, and annealing.

What’s more, the high-performance quartz interior delivers three distinct advantages:

- ENSURE NON-CONTAMINATING cleanroom conditions for delicate samples

- EXTENDS THE LIFE of the heating elements

- ENHANCES TEMPERATURE CONTROL for even more precise thermal treatment

WHAT IS A VACUUM MUFFLE FURNACE?

A muffle furnace contains a rectangular central chamber surrounded by electrical heating elements, which are generally connected to a programmable, digital controller. This space-efficient chamber design offers terrific capacity per dollar.

But standard muffle furnaces have a limitation: perfect inert gas saturation is elusive. Oxygen levels can remain stubbornly high near the corners, due to the non-crossing streamlines phenomenon.

We have solved this problem by fitting a vacuum pump to our proven, benchtop muffle furnace design. This ensures complete atmospheric control without space constraints of a tube furnace.

Most muffle furnaces also have a ceramic interior, which incurs a small risk of contamination or, rarely, dust combustion. We offer a quartz interior for absolute sample purity: unlike ceramic, it is inherently free of any powdery surface or residue. In addition, quartz increases heating element lifespan in the presence of inert gases.

Tube furnaces for battery research remain popular as well. They don’t rival the space-efficiency of a muffle furnace, but they often make sense for extreme temperature and/or very small treatment.

We equip battery, semi-conductor, and other ceramic/metal material research labs with:

- A quartz chamber to maximize sample purity and heating element longevity

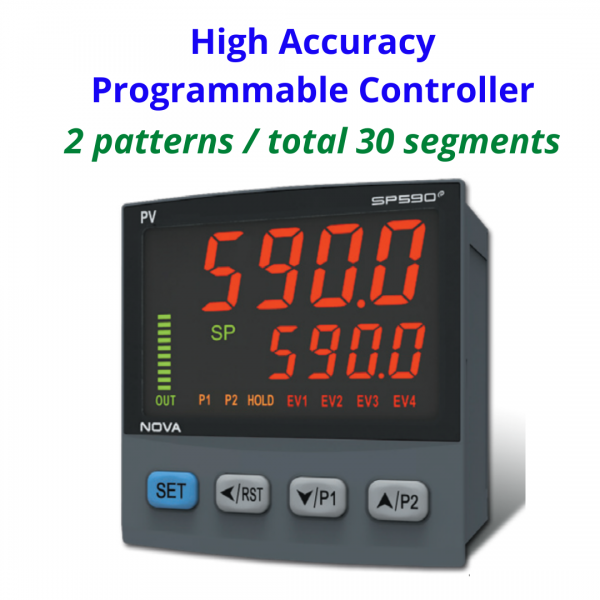

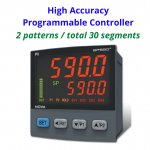

- A programmable digital controller

- An optional mass flow controller for precise, responsive and stable gas management across 98 inert gas presets, supported by a back pressure regulator to maintain positive pressure inside the chamber

- An available vacuum pump with flow speed of 596L/min (21cfm)

Specification

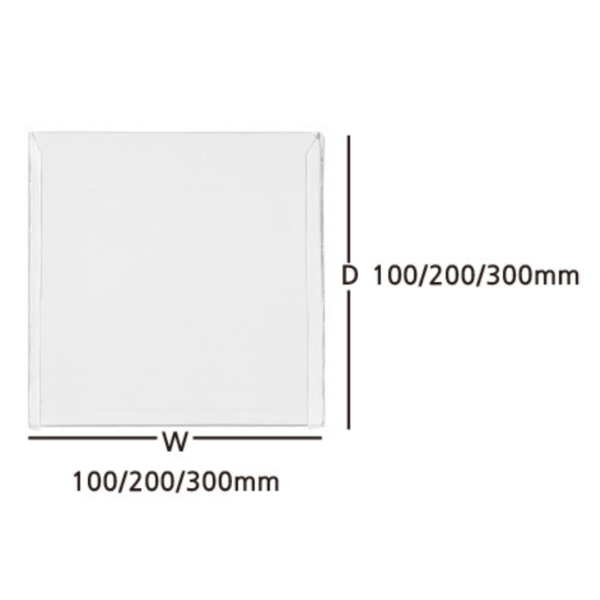

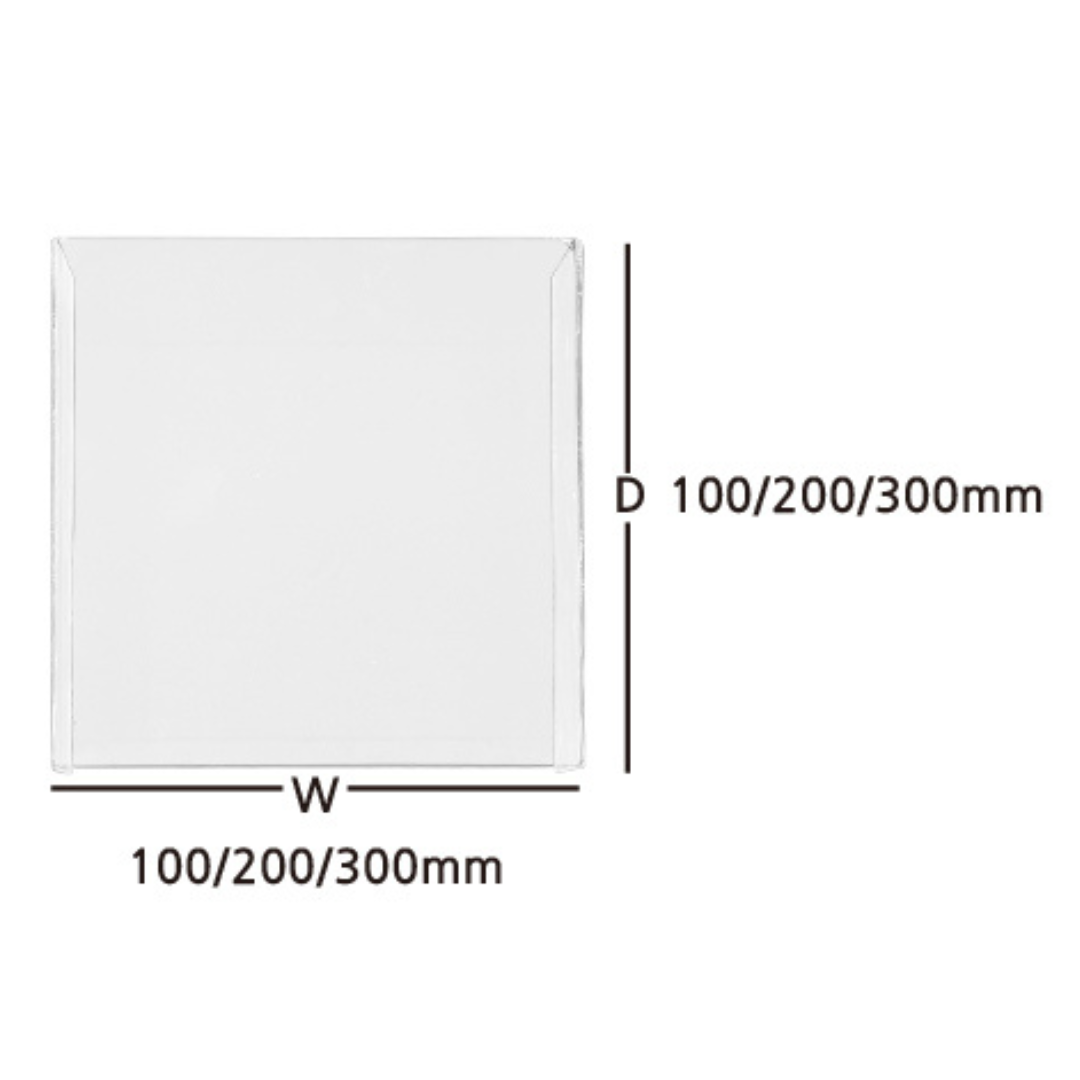

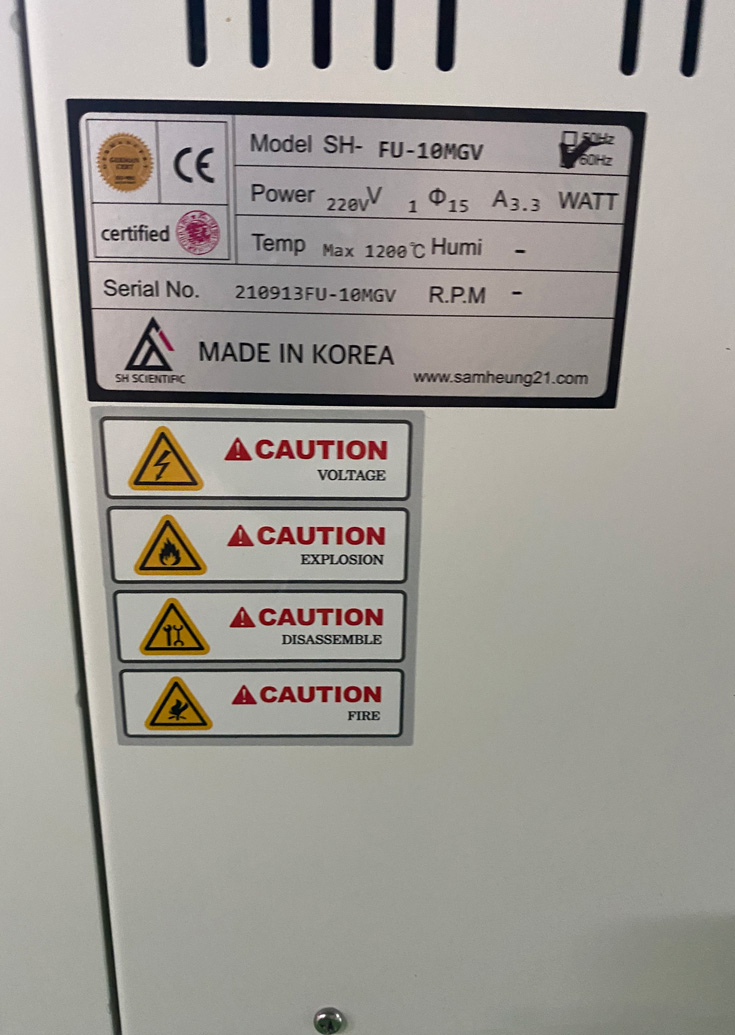

| Model | SH-FU-1.5MGVQ | SH-FU-10MGVQ | SH-FU-31MGVQ |

|---|---|---|---|

| Max temperature | 1200°C | 1200°C | 1200°C |

| Continuous running temperature | 1000°C | 1000°C | 1000°C |

| Chamber volume | 1.3liters | 9.3liters | 29.8liters |

| Controller | SP590 programmable controller | SP590 programmable controller | SP590 programmable controller |

| Heater | 0.8kW | 3.3kW | 6.0kW |

| Sensor | K type | K type | K type |

| Heating element | KANTHAL A-1 (ceramic heating) | KANTHAL A-1 (ceramic heating) | KANTHAL A-1 (ceramic heating) |

| Insulation | Ceramic board & wool (ceramic fiber) | Ceramic board & wool (ceramic fiber) | Ceramic board & wool (ceramic fiber) |

| Chamber size | 109x112x109mm | 209x212x209mm | 309x312x309mm |

| External size | 530x490x730mm | 630x590x830mm | 730x690x930mm |

| Option | Digital vacuum meter Mass flow controller Back pressure regulator |

Digital vacuum meter Mass flow controller Back pressure regulator |

Digital vacuum meter Mass flow controller Back pressure regulator |

| Power supply | 220V, 50/60Hz, 1p, 6A | 220V, 50/60Hz, 1p, 14A | 220V, 50/60Hz, 1p, 26A 220V, 50/60Hz, 3p, 15A |

Customer Photos

Documents

Reviews (0)

Only logged in customers who have purchased this product may leave a review.

FAQ

Content missing

Reviews

There are no reviews yet.