The Behind-the-Scenes Report: How Labs Manufacture LK-99, a Potential Breakthrough in Room-Temperature Superconductivity.

Findings around LK–99, a purported room-temperature superconductor (RTSC), have stirred both excitement and skepticism in the scientific community.

If confirmed, the materials science world may be on the cusp of an epochal breakthrough. If not, the discussion is the latest chapter in the fruitless, decades-long pursuit of a RTSC.

A superconductor is a material with virtually no electrical resistance. Among other properties, it conducts electricity with essentially no heat output.

In principle, superconductivity could transform everything from telecom and air conditioning to maglev trains and quantum computing. In practice, it’s limited to more arcane applications, since all known superconductors require extraordinary temperatures and pressures.

That is, perhaps, until recently.

In a July 23rd arXiv preprint and an accompanying patent, Korean researchers claim to have synthesized LK–99 and verified its superconductivity at ambient pressure and temperature.

The team comprised:

- Sukbae Lee – Quantum Energy Research Centre, Inc. (Seoul, South Korea)

- Jihoon Kim – Quantum Energy Research Centre, Inc. (Seoul, South Korea) & ICT Basic Research Lab. ETRI (Daejeon, South Korea)

- Hyun-Tak Kim – Department of Physics, College of William & Mary (Williamsburg, VA, USA)

- Sungyeon Im – Quantum Energy Research Centre, Inc. (Seoul, South Korea)

- SooMin An – Quantum Energy Research Centre, Inc. (Seoul, South Korea)

- Keun Ho Auh – Quantum Energy Research Centre, Inc. (Seoul, South Korea) & Hanyang University (Seoul, South Korea)

Media discussion reached a fever pitch following a video posted on August 1st. In this clip, shared on the Chinese video platform Bilibili, a researcher claims to demonstrate the material’s superconductivity at ambient pressure and a modest temperature.

LK–99, or Pb10-xCux(PO4)6O in chemical notation, was first discovered and produced in 1999 by a team at Korea University in Seoul. However, years of controversial research and a recent flurry of papers have failed to convince researchers.

The backstory of LK–99 and RTSCs in general warrants skepticism. But as scientists worldwide rush to replicate these findings, this rapidly evolving story may reach a conclusion before long.

How is LK–99 made?

The synthesis of LK–99 requires several stages of precise thermal treatment under varying atmospheric conditions. The researchers’ July 23rd paper describes the following process:

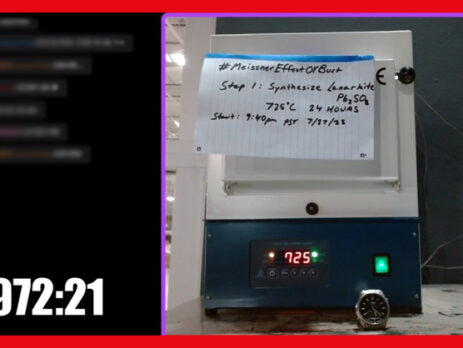

- Obtain Lanarkite by heating mixed (II) oxide and lead(II) sulfate powders in a furnace at 725 °C for 24 hours.

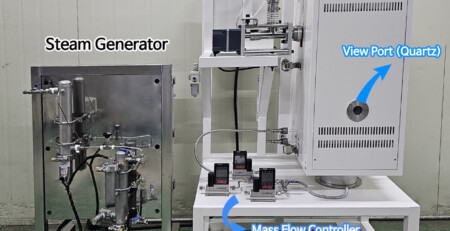

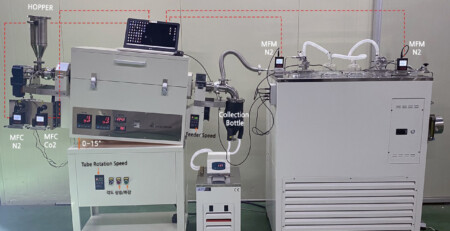

Recommended equipment: standard tube furnace (no vacuum required) or quartz-chamber muffle furnace. - Mix copper and phosphorus powders in a crystal tube, and heat it at 550 °C for 48 hours in a vacuum of 10-3 torr.

Recommended equipment: vacuum tube furnace. - Pulverize the products of the first two steps, seal them in a crystal tube, and heat it at 925 °C for 5-20 hours in a vacuum of 10-3 torr.

Recommend equipment: vacuum tube furnace.

LK–99 production is a delicate and low-yield process. Successful replication and maximum yield demand a high-quality furnace with precise, uniform temperature and consistent vacuum conditions.

That’s a high bar, so we were all the more excited to learn that the team used an SH Scientific muffle furnace for the first step described above.

Trusted by cutting-edge researchers

Leading research facilities have trusted SH Scientific for upwards of four decades. We equip renowned semiconductor and electrochemical labs worldwide.

Specific to RTSC research, we’re proud to supply:

- Seoul’s Quantum Energy Research Centre, including the team behind July’s potential breakthrough.

- Seoul’s Korea University—the very institution affiliated with LK–99’s discovery and initial manufacture, and an ongoing SH Scientific customer and partner.

Our vacuum-equipped tube and muffle furnaces set a new standard in value and customizability.

With uncompromising quality control and US-based support, we make it simple and cost-effective to equip your facility for thermal treatments that enable the materials of the future.

Discover the breadth of applications our customers are pursuing, or reach out directly to discuss technical details, pricing, and customization specifications.