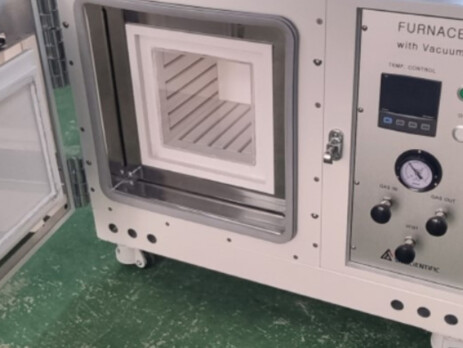

Introducing the Future: SH Scientific’s Exclusive Quartz Chamber Vacuum Muffle Furnaces

Our groundbreaking MGVQ line offers the first and only vacuum muffle furnaces equipped with a quartz chamber.

The quartz upgrade is ideal for delicate or highly corrosive samples, delivering best-in-class cleanroom conditions and an extended heating element lifespan.

Customer Testimonial: Why Choose a Quartz Chamber?

A large part of our clientele is in the battery industry. One such customer recently opted for an MGVQ furnace, and kindly took the time to explain their criteria and priorities.

Heating element & retort/chamber lifespan

“We’ve had innumerable issues with our other furnaces regarding the lifespan of both their heating elements and their retorts. We figured that quartz retort assists with prolonging the lifespan of the heating elements, and would be less susceptible to warping (and thus, eventually cracking) when compared to the alloy retorts in our other furnaces. Another characteristic that’s specific to our process – The byproducts we generate during pyrolysis are actually able to etch into Inconel alloys over time, but they do not etch into quartz.”

Key takeaways:

- Heating elements and retorts often deform and fail over time.

- Quartz resists byproducts that can etch even high-performance alloys like Inconel.

Chamber purity

“We also wanted to find a retort material that was less susceptible to absorbing / adsorbing gaseous byproducts formed during pyrolysis – byproducts which could then be reintroduced into the chamber during the following pyrolysis cycle. Our other furnaces composed of Inconel alloy & ceramic need to be purged not unlike the degassing procedure with this SH model, but we figured that once it’s been degassed, the quartz lining would add an extra layer of protection for our samples from any byproducts that may be absorbed / adsorbed by the surrounding alumina insulation.”

Key takeaways:

Ceramic and Inconel may absorb a tiny amount of gaseous byproducts of pyrolysis.

Quartz will not, which means a much lower chance of exposing future samples to the byproducts of previous cycles.

Cleaning

“We figured it would be easier to clean quartz than it would be to clean Inconel alloy or ceramic.”

Key takeaways:

- Quartz is generally the lowest-maintenance chamber material.

- It’s dust-free (more on this below) and does not leave residues.

Other Advantages Over Alloy or Ceramic Chambers

Standard ceramic chambers are cost-effective and versatile, but they aren’t suitable for all thermal processes.

The main concerns are contamination and combustion. Ceramic materials can release minuscule particles or fibers into the furnace atmosphere, potentially contaminating and/or reacting with the samples. This is of particular concern in oxidizing/reducing atmospheres and around samples that require exceptionally high purity.

There’s also a rare but real possibility of dust combustion, as powdery ceramic residues interact with flammable materials or gases. Intensive cleaning and maintenance protocols are helpful and necessary, but not sufficient to eliminate combustion risk.

Over time, chamber wear and tear can also permit contamination or corrosion of the heating elements. Extreme degradation, like cracking or warping, can even disrupt the chamber’s thermodynamics.

When Do Quartz Chambers Make Sense?

Quartz chambers are costlier, but also non-contaminating, non-reactive, and extremely resilient within their intended temperature range.

These attributes become more valuable as purity requirements become more stringent.

A salient application is battery research. Many battery materials require absolute purity and non-oxidation. To that end, tube furnaces are a standard, effective choice. Unfortunately, cylindrical chambers aren’t conducive to larger samples or higher throughput.

As a solution, battery researchers are turning to our quartz-chamber, vacuum-equipped MGVQ muffle furnaces. With cleanroom-like conditions as well as complete atmospheric management, these are the only devices on the market capable of thermally treating such delicate samples at scale.

Learn More About Our MGVQ Furnaces

Every furnace we deliver has been built in South Korea and tested extensively for consistent, uncompromising performance. Each features:

- Our unique quartz chamber for sample purity and heating element lifespan.

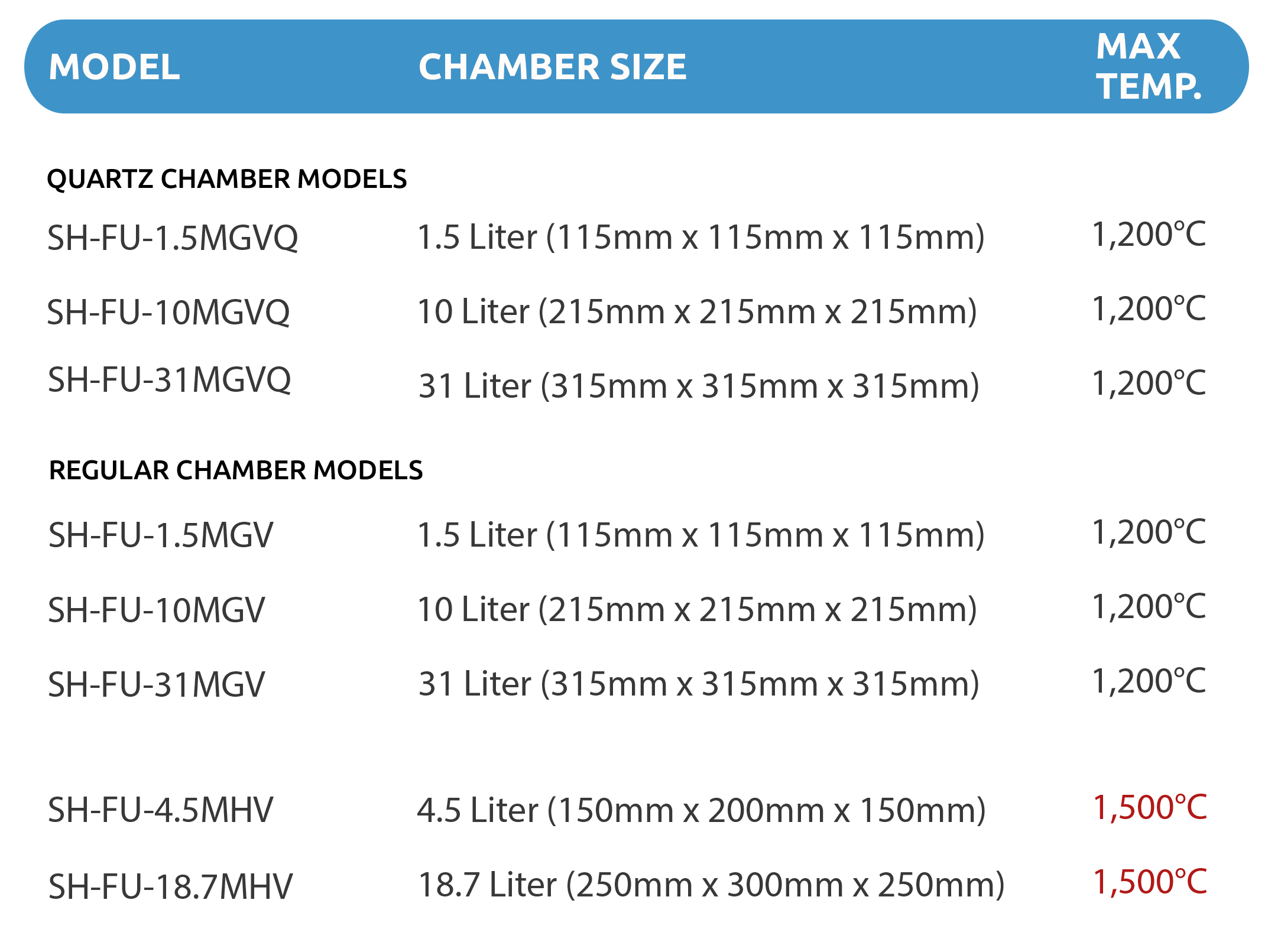

- Chamber volume of 1.3, 9.3, or 29.8 liters.

- A programmable digital controller, optional digital mass flow controller, and optional low-noise vacuum pump for absolute control and repeatability.

Beyond our standard offerings, we can also fulfill almost any custom volume, temperature, or material specs.

To learn more or request a quote, please contact us today.