Research Highlights From the 243rd Electrochemical Society Meeting

The 243rd Electrochemical Society Meeting was a phenomenal window into cutting-edge research, and an all-around highlight of our year.

Our furnaces are the result of years of painstaking design and testing, so it’s incredibly gratifying to see the findings that they support.

Below are a few (of many) noteworthy projects that we’re eager to highlight.

University of Wisconsin & Department of Energy (USA)

Researchers from the UW–Madison and the DOE’s National Energy Technology Laboratory shared research titled “A New Interstitial Oxide Ion Conductor for Low Temperature Applications.”

An “interstitial oxide ion conductor” means that oxygen ions can move around within the small spaces (or “interstices”) in the material. This kind of movement is essential for many electrochemical processes.

The final pellets promise excellent conductivity thanks to quicker, easier ion movement. They proved especially helpful at lower temperatures, which could help certain fuel cells, batteries, and sensors to run longer and more efficiently.

For similar research, we recommend the SH-FU-MG 1200° C muffle furnace.

University of Birmingham (UK)

A team from England’s University of Birmingham shared a poster titled “Impact of altering the catalyst bed ratio in two reactors in series.”

The objective was to expedite the conversion of carbon dioxide (CO2), a greenhouse gas, into methane (natural gas) using a catalyst.

This work may have interesting implications for environmental science and energy production. The more efficiently we can convert CO2 into methane, the more we can simultaneously reduce CO2 emissions and produce a useful energy source (methane).

For similar research, we recommend:

- The SH-FU-MG 1200° C muffle furnace for calcination.

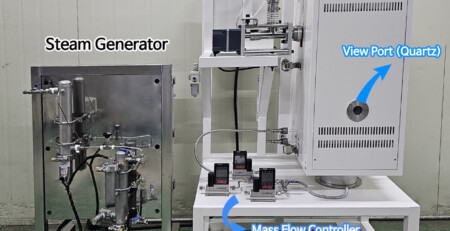

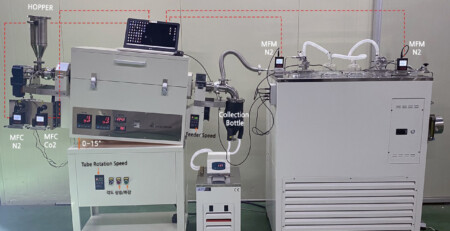

- The SH-FU-STG-WG 1200° C tube furnace + gas supply system for testing catalyst synthesis.

Forschungszentrum Jülich & RWTH Aachen University (Germany)

A team from the Jülich Institute of Energy and Climate Research and the RWTH Aachen University Institute of Physical Chemistry presented research titled “Performance and Electrochemical Behavior of LSM Based Fuel Electrode Materials under High Temperature Electrolysis Conditions.”

They determined that the weight of LSM/8YSZ/LSM+YSZ/LSM (used in fuel cells) changes significantly when exposed to oxidation or reduction at temperatures up to 1000° Celsius.

Their findings expand our understanding of optimal temperatures for these electrode materials, which may help others to design more efficient fuel cells.

For similar research, we recommend:

- The SH-FU-STG-WG 1200° C tube furnace + gas supply system for oxidizing and reducing.

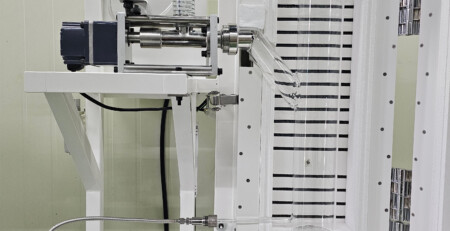

- The SH-FU-TH-WG 1500° C tube furnace + gas supply system for sintering.

Korea Advanced Institute of Science and Technology

Researchers at the KAIST Department of Materials Science and Engineering presented on the “Effect of Acid Leaching Post-Treatment Process on the Structural Stability of Pt-Based Intermetallic Catalysts for Fuel Cell Applications.”

They discovered that annealing improves the efficiency (i.e., current density and mass activity) of platinum alloy catalysts.

This is a useful finding for polymer electrolyte membrane fuel cells (PEMFCs), in particular, which are especially useful in transportation and power generation.

For similar research, we recommend:

- The SH-VDO-NG vacuum drying oven for drying.

- The SH-FU-STG-WG 1200° C tube furnace + gas supply system for annealing.

Kyushu University (Japan)

Kyushu University scientists shared an “Investigation of Surface Oxide Layer Structure to Improve Durability of Stainless Steel Under Humidified Hydrogen.”

They demonstrated that a certain type of stainless steel, JIS SUS430J1L, is exceptionally resistant to water oxidation, and becomes even more durable following thermal pre-treatment.

Domains like chemical processing, energy production (particularly fuel cells), and even space travel put stainless steel through extreme stress. The Kyushu team’s findings suggest a way to improve its lifespan, thereby reducing costs and waste.

For similar research, we recommend the SH-FU-STG-WG 1200° C tube furnace + gas supply system.

University of Tokyo & Tokyo Institute of Technology (Japan)

This Tokyo-based team presented work on “Electrode-Supported Protonic Ceramic Electrolysis Cells for Ammonia Electrosynthesis at Intermediate Temperatures.”

The project focused on ammonia production with PCECs of various materials. Production seemed to be optimal at around 600° C, regardless of current density.

Industries like agriculture and waste treatment use enormous quantities of ammonia, but it also factors into hydrogen storage and fuel cells. These findings clarify the possibilities for producing ammonia at moderate temperatures with electricity, as opposed to the prevailing (and less sustainable) processes with high heat and pressure.

For similar research, we recommend:

- The SH-FU-TS-WTG 1800° C tube furnace + gas supply system for sintering at 1600° C and up.

- The SH-FU-STG-WG 1200° C tube furnace + gas supply system for sintering at up to 900° C.

Technical University of Denmark

Scientists at the Technical University of Denmark’s Department of Energy Conversion and Storage shared findings on “The Effect of Temperature on Galvanostatic Operation of Solid Oxide Electrolysis Cells.”

Apparently, solid oxide electrolysis cells (SOECs) exhibit faster voltage degradation at lower operating temperatures. Degradation was minimal at 900° C, the upper end of their testing range.

These results have the potential to improve more effective energy storage with SOECs. They’re likely applicable to grid stabilization, and perhaps even hydrogen production.

For similar research, we recommend the SH-FU-STG-WG 1200° C tube furnace + gas supply system.

University of Taru (Estonia)

A team from the University of Tartu’s Institute of Chemistry shared learnings from a “Solid Oxide Electrolysis Cell” fabrication project.

SOEC construction techniques have significant performance and durability implications. Their potentially novel technique (the application of a GDC layer) may represent a notable improvement.

For similar research, we recommend the SH-FU-MH 1500° C muffle furnace.

Korea Institute of Energy Research

Representatives of KIER’s High Temperature Energy Conversion Laboratory presented experimental work titled “Nd based Surface Modification to Prevent High Temperature Oxidation of a Ferritic Stainless Steel.”

The findings suggest a novel Nd surface modification that reduces the oxidation of SUS430 steel, especially at temperatures above 600°–800° C (depending on the oxidation compound in question).

This experiment, like several others we’ve shared, may help create more resilient stainless steel products for use in everything from power plans to engine parts.

For similar research, we recommend the SH-FU-MG 1200° C muffle furnace.

Kyushu University (Japan) & University of Illinois (USA)

Kyushu University’s Next-Generation Fuel Cell Research Center and UI–Urbana-Champaign’s International Institute for Carbon-Neutral Energy Research featured their collaboration on “Reversible Solid Oxide Cells: Cycling and Long-term Durability of Air Electrodes.”

In other words, they tested the long-run viability of r-SOCs under realistic working conditions, which include switching repeatedly between SOFC and SOEC operation at high temperatures.

The research furthered our understanding of both SOFC and SOEC reliability, and may ultimately improve energy storage through enhanced r-SOC designs.

For similar research, we recommend the SH-FU-TH-WG 1500° C tube furnace + gas supply system.

King Fahd University of Petroleum & Minerals (Saudi Arabia)

Finally, for now, is an experiment from King Fahd University on “Growth of Carbon Nanotubes on Metallic Substrate: Growth Mechanism and Electrochemical Applications.”

Their goal was to test the feasibility, quality, and (above all) electrical performance of CNTs grown through chemical vapor deposition.

Breakthroughs in energy storage (not to mention sensors and general electronics) depend on radically more efficient battery technology. Novel CNT growth techniques are poised to pave the way.

For similar research, we recommend the SH-FU-STG-3-WG 1200° C tube furnace + gas supply system.

*****

This year’s ECS Meeting was as fascinating and informative as ever. We’ve enjoyed a front-row seat to groundbreaking findings, and can only imagine what 2024’s Meeting will hold!

Until then, there’s a vast amount of work to be done. Countless labs—perhaps including yours—are expanding operations or even branching into new lines of research.

Our Korean-made furnaces deliver outstanding performance at a remarkably accessible price. To learn more or discuss technical details, please reach out today.