Tube Furnaces for Wafer Oxidation

SH Scientific tube furnaces provide tight thermal and atmospheric control for precise, predictable wafer oxidation.

With chambers for wafers from 2″ to 8″ and up, our line is equally suited to R&D use, instructional labs, academic use, and pilot fabrication.

Turn-key packages also provide a quick start for wet oxidation, dry oxidation, diffusion, and more.

In Brief: Wet vs. Dry Wafer Oxidation

Oxidation turns a silicon wafer into a semiconductor by introducing a thin layer of silicon dioxide.

This process typically runs at 800°–1200° C. The temperature must be tightly controlled because slight inconsistencies may create irregular SiO2 layers that impair the wafer.

Two oxidation methods are widely used.

Dry oxidation occurs in a dry oxygen (O2) environment. It’s the preferred technique for gate oxide application, where thinness and uniformity are more important than application speed.

A tube furnace and gas management system are sufficient for dry oxidation.

Wet oxidation occurs in the presence of water (H2O) vapor. It’s a quicker technique that produces a thicker layer, suitable for barrier layer application.

Wet oxidation also requires a steam generator or, for budget-conscious instructional labs, a heating mantle. We can supply either system as part of a turn-key solution.

Efficient Tube Furnaces for Wafer Oxidation

Our tube furnaces deliver uncompromising performance for researchers while remaining cost-effective for education. For instance, we recently provided a 100-mm diameter furnace to Kennesaw State University for 3” wafer fabrication, as well as two 200-mm diameter furnaces to two private companies for 4” wafer fabrication.

These organizations, among dozens of others, are actively researching oxidation techniques using 3″–6″ wafers.

Why do academic and for-profit customers alike choose SH Scientific?

- Large-diameter chambers: Accommodate wafer sizes from 2″ up to 8″ or even larger, catering to everything from educational experiments to standard commercial boules.

- Exceptional thermal control: Choose from 1 or 3 heating zones, with excellent uniformity at maximum temperatures up to 1800° C. Automatic sliding is a popular upgrade for even more consistent control over heat exposure.

- Turn-key gas and steam management packages: Handle multiple gas flow protocols for dry oxidation, wet oxidation, and diffusion processes, including O2, H2O, and N2 + O2. For wet oxidation, select a stream generator or heating mantle to suit your budget and scale. Several sizes of wafer boats are available.

- Stackable configuration: Install 2–4 units in an optional custom cabinet.

- Uniquely efficient doors and seals: A hinged and water-cooled door assembly makes the entire tube diameter accessible. Our end seals are exceptionally quick to open—no disassembly required—making them a popular tube furnace upgrade in their own right.

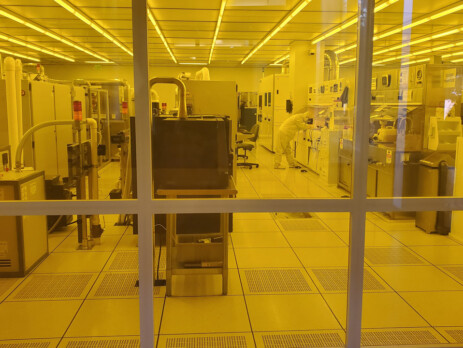

Equipment for the Future of Semiconductor Research

In an increasingly regulated world with mounting trade tensions, domestic semiconductor research is a critical commercial and security objective. This adds up to unprecedented demand for high-performance lab equipment—including tube furnaces.

Thanks to in-house engineering and total control over manufacturing, SH Scientific offers cost-effective furnaces that support today’s research and procurement priorities.

In fact, as the semiconductor industry moves towards larger wafer sizes, we’re one of the few to offer chambers for 10″ wafers as well as virtually limitless customization—even for one-off orders.

If you’re planning to outfit or improve your research or instructional lab, then reach out today to review technical details, discuss custom requirements, or learn more about our business and clientele.