Continuous Vertical Tube Furnaces For Blue Hydrogen Research

Continuous vertical tube furnaces from SH Scientific enable tomorrow’s techniques for sustainable hydrogen production.

With exceptional thermal management and atmospheric control, our furnaces support cutting-edge research on methane pyrolysis for blue hydrogen production.

For instance, a team at the Korea Institute of Energy Research (KIER) used an SH furnace to achieve higher hydrogen yield at lower temperatures than ever before.

This article will briefly discuss the nature of blue hydrogen research, then share how our technology supports KIER in the real world.

Blue hydrogen for green energy

Hydrogen is abundant and clean, but it’s generally difficult to access and utilize.

In practice, as much as 96% is so-called “grey hydrogen,” derived from natural gas or coal through a process called steam methane reforming (SMR).

SMR involves reacting fossil fuels with steam under high temperatures, splitting the feedstock into hydrogen and carbon monoxide. SMR is straightforward, even with existing infrastructure. However, it’s a relatively “dirty” technique that emits roughly 10 kg of CO2 for every 1 kg of hydrogen produced.

Unless or until hydrolysis becomes more scalable, the best alternative is to focus on “blue hydrogen” via improved carbon capture and storage (CCS).

Methane pyrolysis: a cleaner SMR alternative

SMR emits carbon in gas form, which limits CCS efficiency. Emerging blue hydrogen research seeks to create solid carbon byproducts that are relatively easy to capture and store.

The primary technique is methane pyrolysis. It involves the non-oxidizing decomposition of methane into hydrogen gas and solid carbon. Natural gas is still used, but byproducts are readily captured and stored, not freely emitted.

These solid byproducts are useful for carbon black, graphite, or even carbon nanotubes. Depending on exactly how the outputs are sequestered or utilized, the whole process may be carbon-neutral or even carbon-negative.

However, compared to SMR alone, methane pyrolysis requires exceptionally high heat and precise atmospheric management.

A continuous vertical tube furnace is crucial for those conditions.

Equipping researchers for blue hydrogen breakthroughs

The Korea Institute of Energy Research (KIER) is South Korea’s premier center for energy technology R&D. As one of 25 member institutes of the National Research Council of Science and Technology, it’s tasked with advancing living standards and security by developing new energy sources and making existing ones more efficient.

Clean hydrogen—specifically via methane pyrolysis—is one of the institute’s many areas of active research. Blue hydrogen itself is not novel, but it’s been plagued by low efficiency, which piqued the interest of a team at KIER.

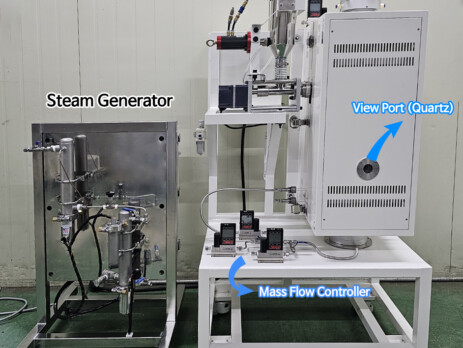

Their work required a continuous vertical tube furnace with several unique features. SH Scientific delivered a turnkey system including the furnace and steam methane reforming (SMR) technology.

In the lab, our collaboration showed significant advancements over existing technologies.

- Lower processing temperatures of just 650°–750° C (vs. ~800° C with existing technology).

- Increased performance of 0.70 A/cm2 at 1.25 V (vs. 0.52 A/cm2 at 1.32 V), meaning more hydrogen and less electricity.

- Increased overall efficiency of 100% at 0.70 A/cm2 (vs. 99% at 0.375 A/cm2).

Supported by our equipment, the KIER team’s findings may lay the groundwork for broader adoption of blue hydrogen as a genuinely sustainable energy source.

Furnace features & customizations

A turnkey package as used by KIER includes:

- Main furnace unit with 2 x gas inlets, 1 x steam outlet, 1 x gas outlet, and 1 x quartz viewing port.

- Moving frame for easy repositioning.

- Feeder capable of about 12–15 g/min, assisted by a clump-reducing vibrating hammer.

- Custom quartz tube, in this case 100 mm ø x 1200 mm with end caps.

- Gas control system with 2 x digital mass flow controllers (for N2 and O2) and 2 x back pressure regulators (upper and lower).

- Chiller and optional low-noise vacuum pump.

- Steam generator for SMR.

The furnace is capable of a maximum temperature of 1200°C via a 600 mm heating zone, with a 220 V, 1-phase, 25 A power supply.

Virtually unlimited customizations are also possible. We realize that needs vary enormously, so we offer in-house design and engineering as well complete control over production.

Why work with SH Scientific?

Your role is to explore and expand energy technology for a more sustainable future. Ours is to provide the equipment you need for meaningful, repeatable, and useful results.

In other words, as your partner in solving real-world problems, we’re here to build the tools that will realize the next great breakthrough.

Whether you’re equipping your lab with a vertical tube furnace, or pushing the boundaries of energy production in other ways, reach out today to discuss how SH Scientific can help.